The 350,000-sf Duan Family Center for Computing & Data Sciences at Boston University (BU) brings 3,000 students, faculty, and staff together daily inside a LEED platinum-certified 19-story structure that sits at the heart of the university’s main campus. By replacing most of the building’s Portland cement with other supplementary cementitious materials, installing triple-glazed windows and fins to reduce the solar load, and heating and cooling the building with geothermal boreholes paired with active chilled beams, the project team created one of the largest sustainable and operationally fossil-fuel-free buildings in Boston.

Stack ’Em High

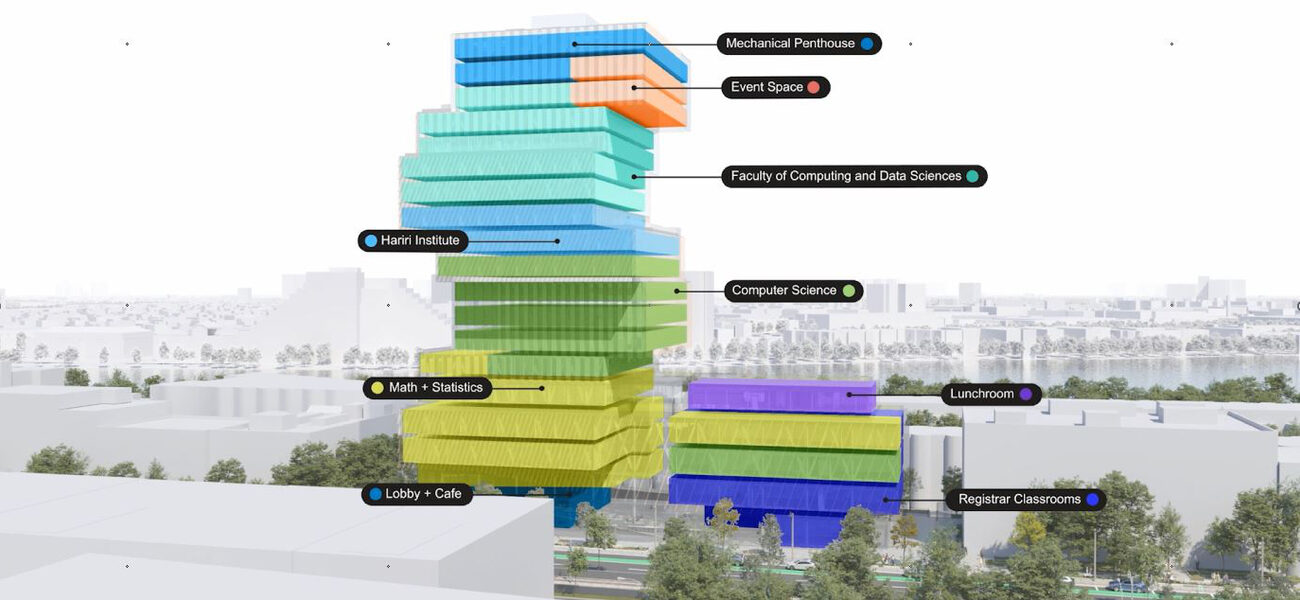

With a daring design that has been compared to a stack of books or a tower of Jenga blocks, the Duan Center was intended from the start to serve as a vertical campus that encourages interactions by blending open, shared gathering and meeting spaces with classrooms, laboratories, and collaborative research areas.

Although the building primarily accommodates the computer science, mathematics, and statistics departments, and the Rafik B. Hariri Institute for Computing and Computational Science & Engineering, it also contains teaching spaces that are bookable by any BU department. As a result, it’s likely that “all students on campus will spend some time in this building,” according to Paulo Rocha, partner at KPMB Architects.

Rocha highlights the fact that the building was designed around a series of two-story and three-story research neighborhoods that shift by one structural bay as they rotate clockwise around the core. This rotational shifting creates the space for a total of eight outdoor terraces that allow people on the upper floors of the building to access the outdoors and connect with nature. The terraces not only provide aesthetic benefits, they also feature green roofs intended to moderate the flow of rainwater, reduce ambient temperature, contribute to air purification, boost the thermal performance of the structure, and extend its lifespan.

Let There Be Just Enough Light

The Duan Center uses multiple strategies to reduce its environmental footprint. Renewable energy to power the building is sourced from a mix of on-campus solar plus off-campus wind. A high-performance building envelope, enhanced HVAC systems, heat recovery, and energy-efficient lighting all combine to minimize energy consumption by 30%.

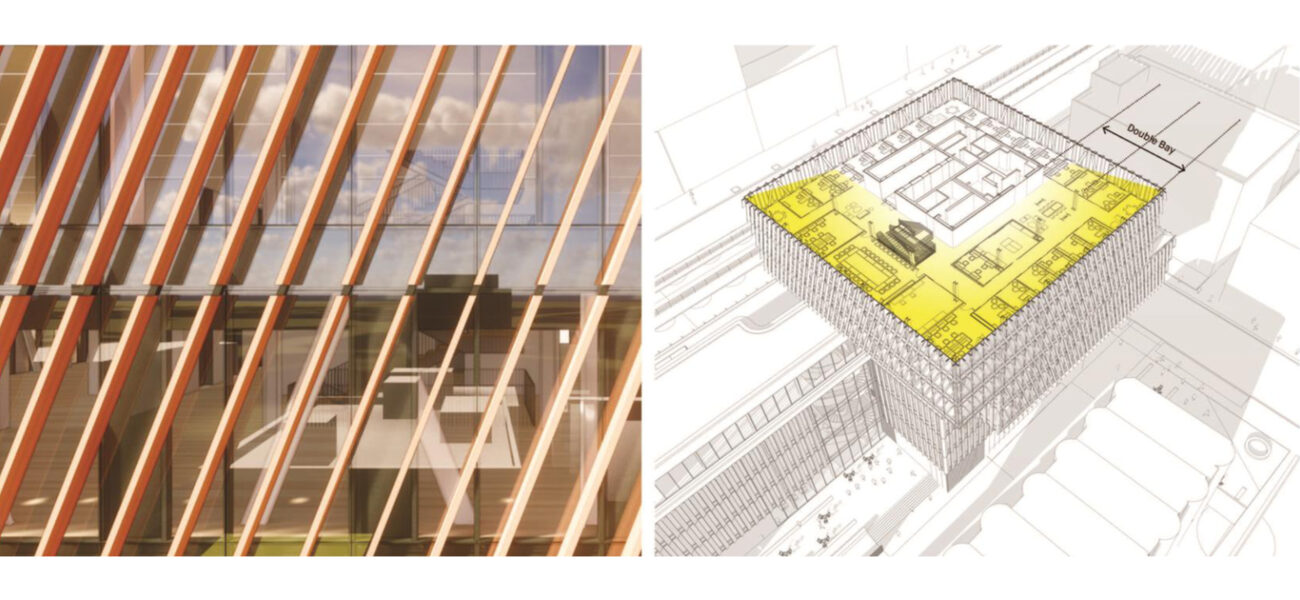

The façade uses a combination of tripled-glazed glass, diagonal louvers, and mirroring in different areas to control the transmission of light and heat, while still providing access to natural light and scenic views.

“As a rule of thumb, horizontal louvers are an effective shading device for southern exposures, while vertical louvers are effective for east and west exposures,” says Rocha. “These two opposing shading strategies posed a challenge for us, because we wanted continuity of the façade… So, we asked our engineers if we could meet in the middle with a diagonal louver. Through 3D modeling and testing, we were able to optimize the angle of the louvers and determine that they would effectively optimize thermal performance and lower solar heat gain during the cooling season.”

Faculty floors feature an abundance of spaces designed to host both formal and informal gatherings. Instead of corner offices, there are open and bookable spaces where all users can meet to collaborate. Many of the rooms are modular with the flexibility to accommodate single, double, triple, or quadruple occupancy.

The designers used color as a primary wayfinding tool. Spaces that face the Charles River are color-coded blue, while those that face Fenway Park are colored green. Floors and neighborhoods within the tower are connected by a stairway along the perimeter of the building which encourages movement, interaction, and serendipitous encounters among occupants.

The design features architecturally exposed structural steel framing, which necessitated the use of an intumescent coating for fire resistance. [Intumescent paint expands rapidly when exposed to high heat to protect the material it covers.] At the time, this was the largest intumescent construction project in the United States. In fact, the construction manager ended up bringing on a second trade partner to handle the volume of intumescent application that the job required.

A Building on a Raft

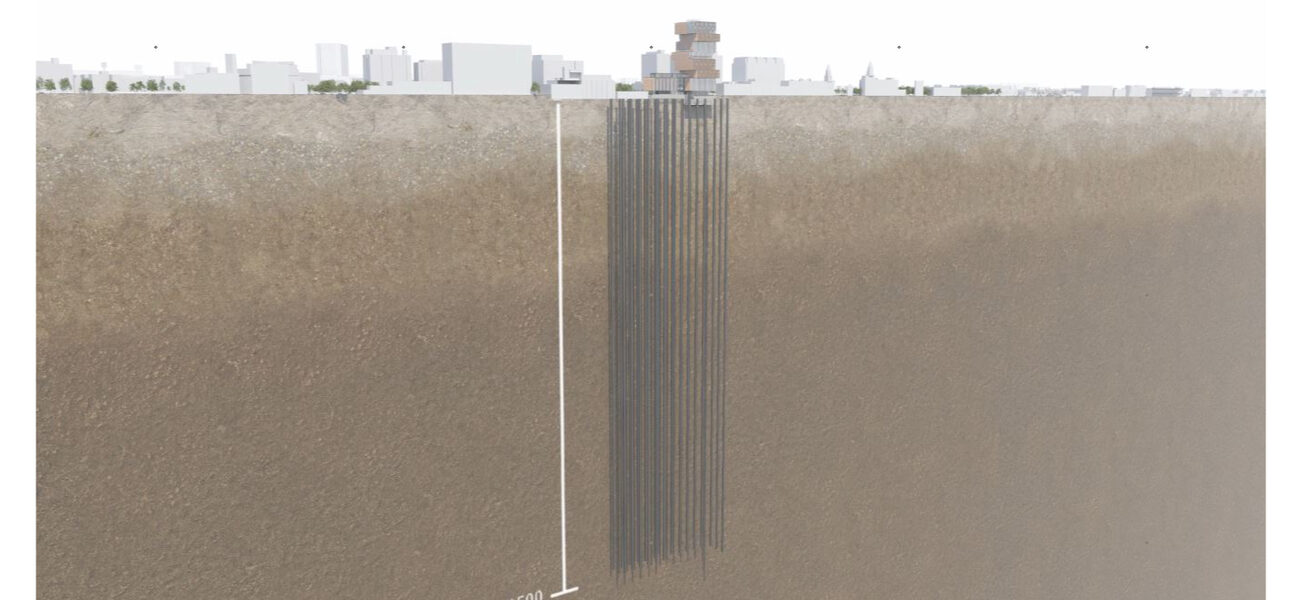

The Duan Center is built in Boston’s Back Bay neighborhood, a former tidal flat. Below grade was 10 feet of fill—bricks and dirt from leveled hilltops—on top of 10 feet of decomposing organic material that had lined the bottom of the bay. Underneath that layer was 10 feet of sand, sufficient to support the five-story brownstone buildings constructed on timber piles that are common in the Back Bay, but not nearly sturdy enough to support a modern Boston high-rise.

“Below the sand is about 170 feet of clay, which makes the site one of the deepest in Boston to get to bedrock,” says Nathan Roy, principal at LeMessurier. “In designing a 300-foot tall building on top of soft clay, our first goal was figuring out a cost-effective way to avoid building another 200 feet down to construct deep foundations.”

The solution was to “float” the building on top of a raft foundation. “Basically, we built a boat and put it into the clay,” explains Roy. “The way a mat foundation works is by balancing the load of the soil that is removed with the weight of the building so that the clay does not ‘know’ any difference.”

To do this required building a concrete mat that ranges in thickness from 3 feet 6 inches to 9 feet. “That’s a lot of concrete, so to reduce the embodied carbon in the building, we worked with local ready-mix suppliers to replace more than 70% of the Portland cement with supplementary cementitious materials (SCMs) that have a much lower carbon footprint,” says Roy. “Ultimately, this became the largest Portland cement replacement ever for this type of project in Boston, and reduced the global warming potential of the building by 6%.”

The floating foundation approach presented a challenge: During a 500-year flood event, hydrostatic pressure could lift the lighter five-story podium. To address this, the team incorporated hold-down piles on the podium side to securely anchor the structure in a flood event.

Managing Electrical and Ventilation Loads

“Traditionally, we would design plug loads to support 4 watts per sf of private office for a building like this,” says Joshua Michaud, associate principal at BR+A Consulting Engineers. “Since this was a data science building, we considered actual metered data from other buildings, held user interface discussions, and considered diversity of occupancy to set a target for total internal design plug load of 1.2 watts per sf.”

To minimize ventilation load, the team reduced its reliance on central systems that are large energy drivers with high static pressures. “We decoupled the ventilation air by using active chilled beams paired with fan-powered boxes,” notes Michaud. “These beams provide a thermal system based on water, which is far more efficient at transferring BTUs than one based on air movement alone.”

Meanwhile, the central ventilation system not only pulls air into the building, it also exhausts air, which creates an opportunity to recover waste heat. The Duan Center uses a dual enthalpy wheel arrangement to reduce both heating and dehumidification loads.

The building relies on geothermal boreholes to supply its heating and cooling needs. The original design called for 100 geothermal boreholes, but given the congested site footprint hemmed in by city streets, BU had concerns about putting so many boreholes underneath the building. So, the number was ultimately revised downward to 31 geothermal boreholes.

“To go from 100 geothermal boreholes down to 31 boreholes and still put the same heat and cooling load into the ground on a sustainable long-term basis, you have to go deeper,” says Michaud. “Most commercial geothermal installations these days go down between 600 and 800 feet. We went 1,500 vertical feet deep. That’s nearly twice the height of the John Hancock Tower, which is the tallest skyscraper in Boston at 790 feet tall.”

The use of High Performance Geo Exchange (HPGX®) fiberglass pipes from the Rygan Corp with corrugated features increases the transfer efficiency of the geothermal borefield. “By making the necessary investments to get every possible BTU from the borefield, we were able to have the geothermal system take care of 90% of our annual heating load,” says Michaud. “To cover the last 10% of heating needs, we have a backup system with electric boilers.”

The geothermal system was also designed with resiliency in mind. Although engineers say that geothermal boreholes tend to outlast the buildings they support, the pipes are theoretically susceptible to damage from excavation or severe earthquakes. Accordingly, the team designed the building so that the heating and cooling system could continue to operate without any major issues, even if the building lost the use of up to eight of its geothermal boreholes.

In the unlikely event that more than eight boreholes fail, the building can accommodate the installation of additional standard mechanical cooling tower equipment to cover its HVAC needs while repairs to the borefield or horizontal piping are performed.

Impressively, all of the choices that were made to improve the project’s sustainability not only gave BU more usable floor space, they only increased the total construction cost for the project by less than 1% over a standard design option.

By Aaron Dalton

| Organization | Project Role |

|---|---|

|

KPMB Architects

|

Architecture, Interiors

|

|

BR+A Consulting Engineers

|

MEP, IT

|

|

Entuitive

|

Structural Engineering, Building Envelope

|

|

LeMessurier Consultants Inc.

|

Structural Engineering

|

|

Compass/Vertex

|

Owner's Project Manager

|

|

Turner & Townsend

|

Cost Estimating

|

|

Richard Burck Associates, Inc.

|

Lansdcape Architecture

|

|

Dot Dash

|

Lighting

|

|

Transsolar

|

Climate Engineering

|

|

The Green Engineer

|

LEED Consulting

|

|

Nitsch Engineering

|

Civil Engineering

|

|

Soberman Engineering

|

Vertical Transportation

|

|

Jensen Hughes

|

Accessibility

|

|

Haley & Aldrich

|

Geothermal

|

|

Acentech, Inc.

|

Acoustics, AV

|

|

RWDI

|

Environmental Engineering

|

|

Learch Bates

|

Façade Access

|

|

Robbie McCabe Consulting

|

Hardware

|

|

Ricca Design Studio

|

Food Services

|

|

Entro Communications

|

Signage

|

|

Norm Li

|

Renderings, Animation

|

|

Brian Ballantyne Specifications

|

Specifications

|