Rice University’s Ralph S. O’Connor Building for Engineering and Science, which opened in September 2023, is a 250,000-gsf center for advanced materials sciences designed to facilitate interdisciplinary collaboration by bringing together researchers in the fields of chemistry, biomolecular engineering, physics, and nanoengineering who had previously been scattered across 13 different buildings around the campus.

“The new O’Connor building replaces a 1940s facility that was top-of-the-line when it was built, but had since exceeded its useful lifespan,” says Angie Chen, senior project manager at Rice. “Building modern, resilient core lab facilities and collaborative spaces can be an important factor in the recruitment of the principal investigators that Rice seeks to attract and hire.”

Indeed, Rice has big plans for the future. The university aims to double both its undergraduate and graduate enrollment over the next four to five years. In the same timeframe, the university expects to add about 200 full-time faculty members, including dozens of principal investigators for the School of Engineering and Natural Sciences, approximately 30% of whom are expected to focus on materials science research.

Rice plans to use the O’Connor building to house three research centers:

- Rice Advanced Materials Institute, which will focus on designing innovative, energy-efficient materials for applications including information and communication technologies, sustainable water supplies, and energy systems.

- Rice University National Research Accelerator, which involves a partnership with the Army Research Lab on developing advanced materials and next-generation networks with applications in intelligence, surveillance, and reconnaissance.

- Nanosystems Engineering Research Center for Nanotechnology Enabled Water Treatment, part of a multi-university collaborative effort to find ways to treat water more affordably using fewer chemicals and less electricity with the help of engineered nanomaterials.

Three Lessons Learned from Another Research Building

Prior to the O’Connor building, Rice’s newest large research facility was the 10-story, 488,000-gsf Bioscience Research Center (BRC) built in 2009. As Rice designed the new O’Connor building, Chen and her colleague Jennifer Koranek, project manager, Facilities and Capital Planning, were eager to incorporate elements that had worked especially well in the BRC and to see where they could make improvements.

One thing they discovered was that researchers were very enthusiastic about the open-concept lab modules in the BRC, with its many open lab bays connected by a central corridor, strategic lab support rooms, and specialty equipment rooms on the other side of that corridor. “The researchers like the ability to feel connected with the whole research floor,” says Koranek.

BRC researchers were generally pleased with the shared resources in their building, including nitrogen, natural gas, CO2, vacuum, compressed air, and autoclave spaces, but they did encounter some constraints over the years with capacity for fume hoods and other chemical exhaust systems. “Rice is very focused on growing engineering and materials labs that need these sorts of exhaust capabilities, so we made sure to include a very high capacity of 250 fume hoods in the O’Connor building,” notes Koranek. She emphasizes that Rice worked with the manufacturer to make sure these new fume hoods were state of the art, with piped-in connections to high-pressured vacuum pump cabinets that eliminated the need to drill holes in horizontal work surfaces.

There were two other ways that Rice wanted to improve on the BRC as it designed the O’Connor building. First, they decided to move student seating closer to the lab space so that entire research groups—including faculty, post-docs, and grad students—could be together in the same area to facilitate better communication.

Also, while BRC itself offered a collaborative environment for researchers in multiple disciplines—including biomolecular engineers, computer engineers, and psychologists—very little of that science was on display. “The science in BRC was very cut off from the public view,” says Koranek. “Even researchers at the BRC can’t necessarily see what their colleagues on other floors are working on.”

By contrast, Rice put architectural and design elements in the O’Connor building central atrium that allow people on any level of the building to see up to the fourth floor or down to the basement. The atrium brings light into all levels of the building and allows researchers and visitors to get a sense of the building as a single unified space.

There’s also a set of stairs at the front of the building behind a glass façade that allows people to walk up into collaboration spaces on each floor while also getting a sense of how the building relates to the rest of the 300-acre campus.

“In the months since the O’Connor building opened, we’ve had the privilege of walking a lot of prospective faculty through the space,” notes Chen. “The robust facilities get a head nod, but the real ‘Wow!’ factor and the thing that draws them in are the collaboration areas and the science on display.”

Getting the Scale Right

One of the major concerns early in the design of the O’Connor building was how to incorporate this advanced materials research center into the rest of the campus. The building sits in an engineering quad nearby the physics, computer science, and chemistry buildings. As such, the goal was to make sure the new building facilitated circulation around campus and enabled students and researchers to access various places around the quad. “We wanted to design a building that would encourage people to pass through and to stop in,” says Chen. “A lot of our design revolved around this idea of attracting both students and the public into a space in the midst of the Rice University campus.”

There was also the matter of making sure the building was the right scale for its location. “One of the main questions we asked ourselves was: How big does this building need to be?” recalls Chen. “What is the massing and stacking that would allow for the types of research that will take place there?”

Ultimately, the university decided that the building’s budget would allow construction of a 250,000-gsf structure, which was distributed between a full basement and five upper floors, with Levels 2 through 4 holding research labs.

The building has breakroom and collaboration areas on each floor, four large conference rooms, 14 smaller meeting rooms, two 100-seat classrooms, a penthouse event space and board room that can hold up to 150 people, and an outdoor event terrace.

Most of the building’s mechanical equipment is on the top floor, freeing up the basement to use as storage space for hazardous materials and as a vibration-mitigated research space, explains Koranek.

This is important because advanced materials research involves equipment where excessive vibration can interfere with accurate measurement. As such, the concrete O’Connor building was designed to have vibration levels below 2,000 mips (micro inches per second) throughout the structure, but the basement performs even better than that. Vibration levels below 500 mips in the basement make that level a suitable place to perform research with ultra-sensitive equipment, such as scanning electron microscopes and transmission electron microscopes.

True Success through Flexibility

Rice committed to construct the O’Connor building as a center for advanced materials sciences, but while they knew what sort of research would take place there, they didn’t know who the researchers would be. “There were no specific principal investigators (PIs) or researchers who were identified in advance as people who would be assigned to specific lab space,” says Chen. “As such, we prioritized flexibility and adaptability. We considered not only how the building could support the current researchers we have at Rice who work on nanomaterials, quantum materials, plasmodic materials, photonic materials, and more, but also how the building could change to meet their needs as their research grows and evolves.”

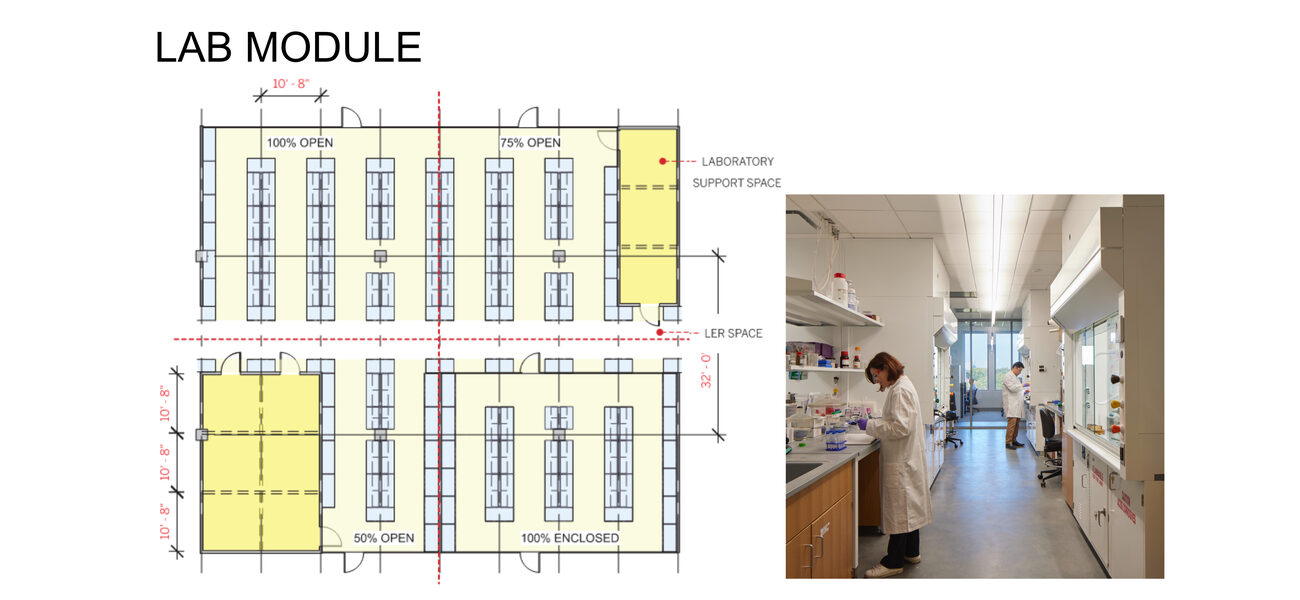

Accordingly, Rice worked with a designer to build lab floors featuring 10-foot-8-inch lab modules with a variety of layouts. Some are typical chemistry labs with fume hood lab benches, while other labs are paired with support spaces, specialty rooms, computational spaces, optics rooms, and other types of dedicated spaces for various materials science disciplines.

Rice also ensured that the ceiling heights were capacious enough to accommodate researchers’ needs. Floor-to-floor ceiling heights are 20 feet on Level 1, 18 feet in the basement, and over 15 feet on Levels 2 through 4. “These ceiling heights are important for some researchers who need the vertical flexibility for equipment that requires higher clearances,” says Koranek. Similarly, Rice made sure that the freight elevator was large enough to fit an 8-foot-by-10-foot laser table used in optics labs.

Benchmarking for the Future

At its opening, the O’Connor building was only 50% built out. The university plans to continue building out the remaining shell spaces to accommodate new hires between now and 2026, so it deliberately put a lot of shutoff controls and shared utilities into linear equipment corridors with open ceilings that provide easy utility access, says Chen. “Having this equipment in the corridors allows to us build out adjacent lab spaces without disrupting and shutting down work in labs that are already active,” she explains.

Rice is already thinking about how to design its next engineering and science building. A benchmarking study showed that the total floorplate efficiency in the O’Connor building—the percentage of floor space devoted to research activities—stood at 65%, which met the goal that Rice had set for itself and compared favorably to representative buildings at other R1 doctoral granting institutions.

The benchmarking did reveal, however, that an average floor in the O’Connor building had only 143 nsf of shared lab support space, which was dramatically lower than the comparable figure for research buildings at peer institutions. “Culturally, at Rice, I think we can drive home the point of having shared equipment,” says Chen. “As we think about our next building, we know this is one of the areas where we want to improve.”

By Aaron Dalton

| Organization | Project Role |

|---|---|

|

Skidmore, Owings & Merrill

|

Architect

|

|

Anslow Bryant Construction Ltd.

|

Construction Manager

|

|

Scientia Architects

|

Programming and Lab Planning

|

|

Jacobs Consultancy

|

Lab Planning

|

|

Wylie Engineering

|

MEP Engineering

|

|

IMEG

|

Structural Engineering

|

|

Walter P. Moore and Associates, Inc.

|

Civil Engineering

|

|

Ulrich Engineers, Inc.

|

Geotechnical Engineering

|

|

Charles M. Salter

|

Acoustics and Vibration

|

|

Loisos + Ubbelohde

|

Lighting and Daylighting

|

|

Stanton Engineering Group, LLC

|

IT/AV/Security

|

|

Edgett Williams Consulting Group

|

Vertical Transportation

|