The research infrastructure department at the Biodesign Institute, Arizona State University’s showcase research center, employs a dedicated facilities service organization with considerable in-house expertise, and granular benchmarking tools that track utilities and facilities costs in multiple categories of lab space, from LEED-certified green building features to general wet labs to secure ABSL-3 labs with a select agent program. In a state-sponsored research environment, where operating costs can go as high as $170 per net sf, optimizing building efficiency is critical. The direct result of these visionary initiatives is a multi-tasking, responsive facilities team that has reduced annual energy expenditures by $1.3 million.

“The facility must operate properly,” says Michael McLeod, director of research infrastructure at Arizona State University (ASU). “Safety is our number one priority, and research is number two. Energy is a critical component to help meet ASU’s carbon-neutral 2025 campus goal. We have discovered that as these buildings mature, we have been able to improve our processes and systems with fewer personnel while still maintaining a very high level of service.”

Streamlined and Nimble Organization

Representing Arizona’s largest bioscience investment to date, the 350,000-gsf Biodesign Institute is projected to grow to 800,000 gsf on maturity. The first two components of its master plan, Buildings A and B, opened in December 2004 and January 2006 and are certified LEED Gold and LEED Platinum, respectively. Total construction cost was $150 million.

The Institute currently comprises 14 centers, each run by a center director preeminent in his or her field. The main scientific focus is on improving health, sustainability, and defense, especially in use-inspired research following nature as a model. (The most visible example is the serum developed through the production of therapeutics in tobacco plants that was successfully used in the treatment of some Ebola patients in the U.S.)

The need for a nimble, responsive facilities organization to support Biodesign occupants was recognized early on.

“Our scientists, many of whom are world renowned, including a 2001 Nobel laureate in medicine, are an intensely focused, dedicated group, and our goal is to make life as easy as possible for them,” says McLeod.

One of the ways to accomplish that was for the research infrastructure group to establish its own work order system and employ a small in-house crew of technicians. While the university’s centralized facilities group, FacMan, still takes care of the “heavy lifting”—long-scheduled projects like a big motor replacement, for example—more immediate tasks, such as office moves, lab equipment installation, and utility connections, are handled internally.

Making extensive use of email communications, this direct approach streamlines the request process for users, offering strict tracking mechanisms, immediate follow-up, and fast response time.

“This is where we broke out of the box,” says McLeod. “Our organization is very customer-service focused. The cost, effort, and inconvenience of a campus-wide system went away. We are somewhat decentralized but not totally decoupled.”

“In my experience, Biodesign facilities responds quickly and efficiently, which allows researchers to stay focused on their science,” says Nobel laureate Dr. Lee Hartwell, who serves as the Virginia G. Piper Chair in Personalized Medicine and the Institute’s chief scientist.

Multi-Tasking

The deployment of personnel in the research infrastructure group represents a marked departure from the traditional university facilities organization. In addition to self-performing shipping, receiving, and delivery functions, the Institute has its own tradespeople (electrician, plumber, and mechanical technician) on staff, a feature warmly applauded by the many operations managers who tour the facility each year, points out McLeod.

“We handle mostly what is in and around the lab, and then, of course, we respond to emergencies if needed,” he says. “It has worked wonders. When you have a massive, monolithic central group with hundreds of technicians, it is easy for small things to fall through the cracks. In contrast, our small team is geared to be very fast and efficient. Researchers love it.”

Multi-tasking and cross-training are common themes in research infrastructure. The electrician doubles as project manager, taking care of permit submissions, while the HVAC technician is also in charge of energy management. When the health and safety position was reduced to half-time as the result of improved operations, the employee received training in space planning and now occupies dual roles.

“The downside is that if you lose a person trained for two spots, you lose both functions,” says McLeod. “But for personnel, they find this approach more rewarding, and it helps to inspire and motivate our staff to learn more and improve their craft. Turnover has been almost zero.”

Blending Scientists into the Operations Group

Extending the concept of cross-functionality, the Institute also tapped the expertise of a research scientist who has been hired to oversee the lab safety program and recertifications, budgeted to run about $20,000 annually. The same scientist recently took on the duties of biocontainment facilities manager, leveraging her expertise and understanding of sophisticated ABSL-3 environments in a blended position.

“Not just anyone can go strolling into a lab to change a light bulb,” says McLeod. “We need someone who knows the systems and can bridge the gap between facilities and research. This is not about cost savings but quality and customer service.”

While there were a few HR hurdles to overcome with reporting relationships, in the end the scientist was able to become a functioning part of the research infrastructure group.

“At ASU, Biodesign is expected to do things differently. Part of our value is the ability to take risks.”

McLeod anticipates that now that this precedent has proved successful, similar provisions can be made for other blended positions that benefit from a combined knowledge of research and facilities operation, such as managing a core lab facility.

There is also more cross-over between research infrastructure technicians and the animal care groups, an area characterized by frequent interaction, cooperation, and learning. These activities occur without the financial stipend of a formal position.

Benchmarking Numbers

As a mixed-use facility, the Institute’s 112,414 nsf of lab space includes a wide variety of lab types:

- Vivarium: 20,270 nsf, 18 percent of the total

- Biological research: 87,636 nsf, 78 percent

- ABSL-1: 4,525 nsf, 4 percent

- ABSL-2: 10,272 nsf, 9 percent

- ABSL-3 (select agent): 1,755 nsf, 1.6 percent

- BSL-1: 20,241 nsf, 18 percent

- BSL-2: 49,139 nsf, 44 percent

- BSL-3 (select agent): 1,704 nsf, 1.5 percent

McLeod emphasizes that calculations are based on net, rather than gross, square footage, a standard that generates more comparable measurements. Costs for debt service, construction, and start-up are not included.

Five major cost categories and their components are used to create operating cost benchmarks per nsf, as illustrated by these numbers for the general wet lab:

- EHS (labor, expenses): $4.08/nsf, 5.8 percent of total

- Security (from a contract provider): $2.84/nsf, 4 percent

- IT (labor, expenses, connectivity, cameras/equipment, computers, intrusion system): $11.60/nsf, 16.4 percent

- Facilities (labor, expenses, O&M, custodial, contractors, service contracts, grounds): $30.36/nsf, 43.1 percent

- Utilities (electrical, chilled water, steam, emergency generators, water): $21.64/nsf, 30.7 percent

- (Animal Care, spread out over 1,700 sf in ABSL-3 labs, averages $36.78/nsf.)

While EHS and security costs are constant across all lab types, higher IT, facilities, and utilities costs significantly drive up the operating totals for the more specialized spaces:

- General wet lab cost, $70.52/nsf.

- BSL-3 lab total cost without select agent program, $88.48/nsf.

- BSL-3 lab total cost with select agent program, $128.70/nsf.

- ABSL-3 lab total cost without select agent program, $128.92/nsf.

- ABSL-3 lab total cost with select agent program, $169.14/nsf.

For example, the utilities cost benchmark for the general lab is $21.64, but, with 83 percent more energy use, the BSL-3 lab benchmark rises to $39.60/nsf. The ABSL-3 uses 100 percent more energy, for a benchmark of $43.28/nsf.

In addition, the select agent program significantly pushes up costs in the facilities and IT categories. Facilities costs are $30.36 for the general, BSL-3, and ABSL-3 labs, compared to $57.78/nsf in select agent spaces. IT costs are $11.60/nsf and $24.40/nsf, respectively.

“War on CFMs”

The Institute is staunchly committed to reducing energy consumption, a real challenge given the rigorous ventilation requirements of biocontainment labs.

“We are moving much more air in those facilities,” notes McLeod. “We figure every CFM costs us around $5. So we are waging a war on CFMs in the building.”

A robust—and almost unprecedented—scheme of metering and monitoring mechanical and electronic equipment not only generates accurate measurements but also provides feedback so malfunctions can be identified and remedied quickly.

“Ubiquitous monitoring allows for our continuous improvement strategy to take flight,” he continues. “Being entrepreneurial, Biodesign was able to secure funding to put meters everyplace we can, recording data in any way possible. For example, we meter electrical usage down to the distribution panel. We have portable metering to measure a room or piece of equipment on a temporary basis, even to the component level, such as an A/C or exhaust pump.

“With that and good charts, we can calculate the costs of an individual room. Almost no one else can really tell you the energy cost of a 12-by-20-foot BSL-3 lab.”

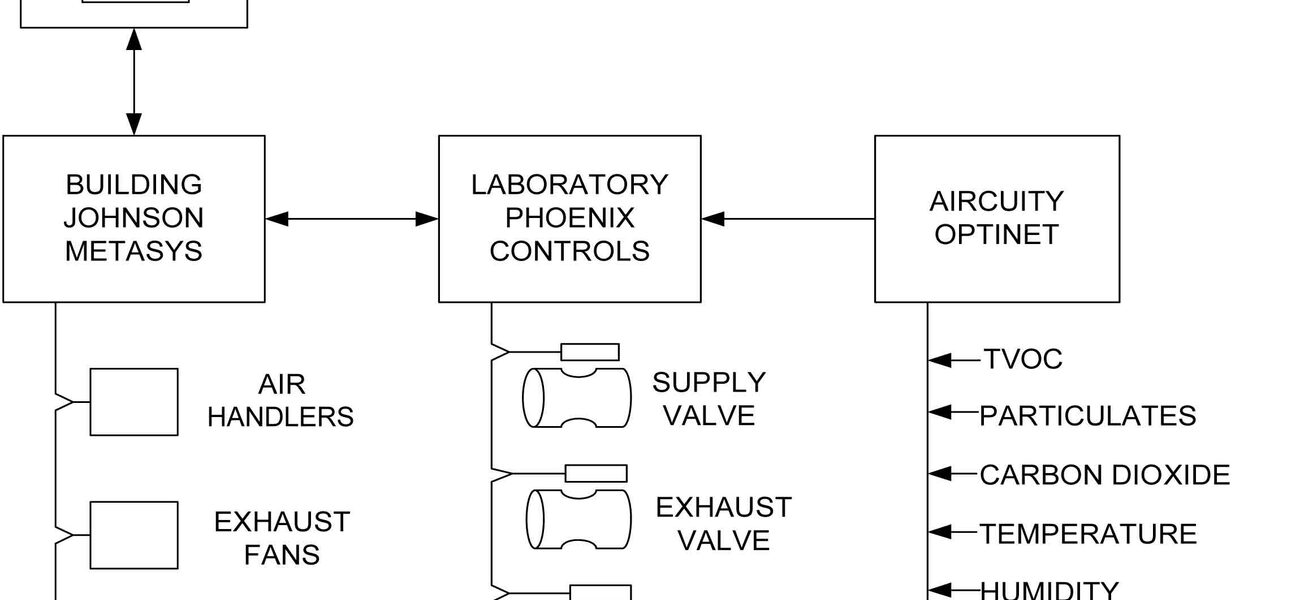

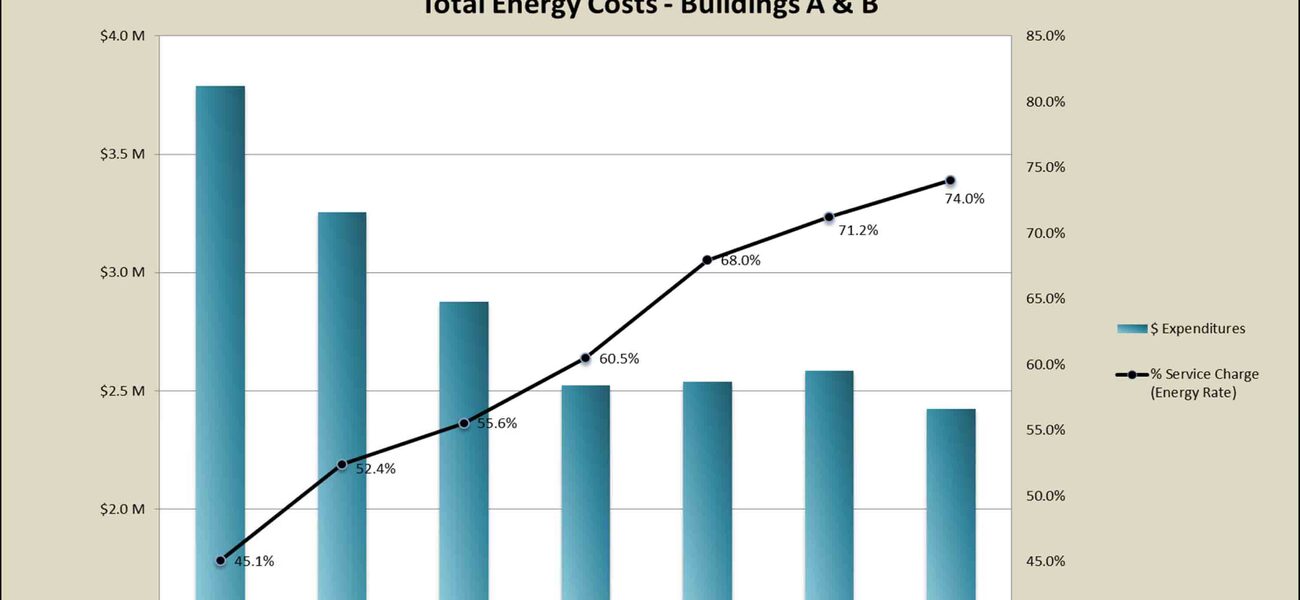

The detailed analysis enabled by the resulting Meter, Monitor, and Manage program revealed that HVAC accounts for 74 percent of total utility costs, quickly tagging it as the prime focus for energy reduction. Beyond encouraging researchers to close fume hood sashes when not in use, conservation measures include a “very complex” HVAC control system that integrates Aircuity® air sampling and centralized sensors with Phoenix Controls® valves to vary air volumes for just-in-time customer use (down to a low of four air changes per hour) while maintaining very tight negative static control. The data feed into a Johnson Controls Metasys® system for fine-tuning all components.

McLeod points out that managing the complexities of the overall scheme frequently exceeds the capabilities of a typical facilities staff, but thanks to Biodesign’s resident expertise, over time the system has been tuned and adjusted to save $1.3 million a year in energy costs.

By Nicole Zaro Stahl

This report is based on a presentation McLeod gave at Tradeline’s 2014 International Conference on Biocontainment Facilities.

| Organization |

|---|

|

Johnson Controls Inc.

|

|

Aircuity Inc.

|

|

Phoenix Controls

|