Build the first 14 floors now, then add a 16-story tower a decade or so into the future. That was Northwestern University’s unconventional approach to the construction of the Louis A. Simpson and Kimberly K. Querrey Biomedical Research Center on the Chicago campus of its Feinberg School of Medicine. It wasn’t the only out-of-the-box decision that enabled the university to move forward with its vision of creating a 1.2 million-sf, next-generation research hub about 10 miles south of its main campus in Evanston. Similarly inventive is the ownership arrangement of the first half, which became the largest academic biomedical research building in the U.S. when it opened in 2019. One of the medical school’s three major hospital affiliates, Ann and Robert H. Lurie Children’s Hospital of Chicago, owns four of the nine lab floors (amounting to roughly 160,000 sf) and has easements to four-ninths of all the common space in the 625,000-sf structure.

The co-ownership strategy is a win for both entities: The pediatric research enterprise has regained proximity to Lurie Children’s Hospital, which had moved to a new building on the lakefront site in 2012. Northwestern benefitted from the significant capital funding the hospital brought to the project. While the agreement was legally complex, building operation is simplified by having the university provide all services, from mail delivery to IT infrastructure.

A mix of factors determined the targeted size of 1.2 million sf for the new research center, including the maximum zoning allowance for the site, the medical school’s ambitious plans for growth, and calculations for potential grant revenue generated by the square footage.

“That amount of space implies around $1 billion of capital to build out and fit out completely,” explains Eric Boberg, Ph.D., executive director for research at the medical school. “We could afford 600,000 sf at the time, but why waste any of the 1.2 million sf allowed? We decided to add the rest later. It made a lot more sense to build out just the base of the building but not the shell and core of the tower, avoiding the need to deal with the operating expenses over an unspecified period of time.”

An Architectural Statement

In its urban setting, sandwiched between another research building and a functioning hospital (the Shirley Ryan Ability Lab), the new facility had additional exigencies to satisfy. The parcel had previously housed a 1970s-vintage hospital that was one of the city’s architectural landmarks. The new structure had to live up to lofty design standards.

The architects, Perkins&Will, were selected as the result of an international design competition. A key element distinguishing their design is the extensive use of glass, which arcs in a dramatic curve on the north façade, near the main entrance to the building. Floor-to-ceiling windows line all nine lab floors and the ground level of the atrium, whose glass panels are unusual in both span and provenance. Measuring 11 by 10.5 feet, the panels had to be procured from Germany; no U.S. manufacturer could produce such a large size.

“The design decision was to bring in as much glass as possible to make the exterior as clean as possible within budget,” comments Boberg. “Importing the super-sized panels wasn’t extravagant relative to the overall budget. We could have economized, but we promised the city an iconic building.”

High-Efficiency Floorplan

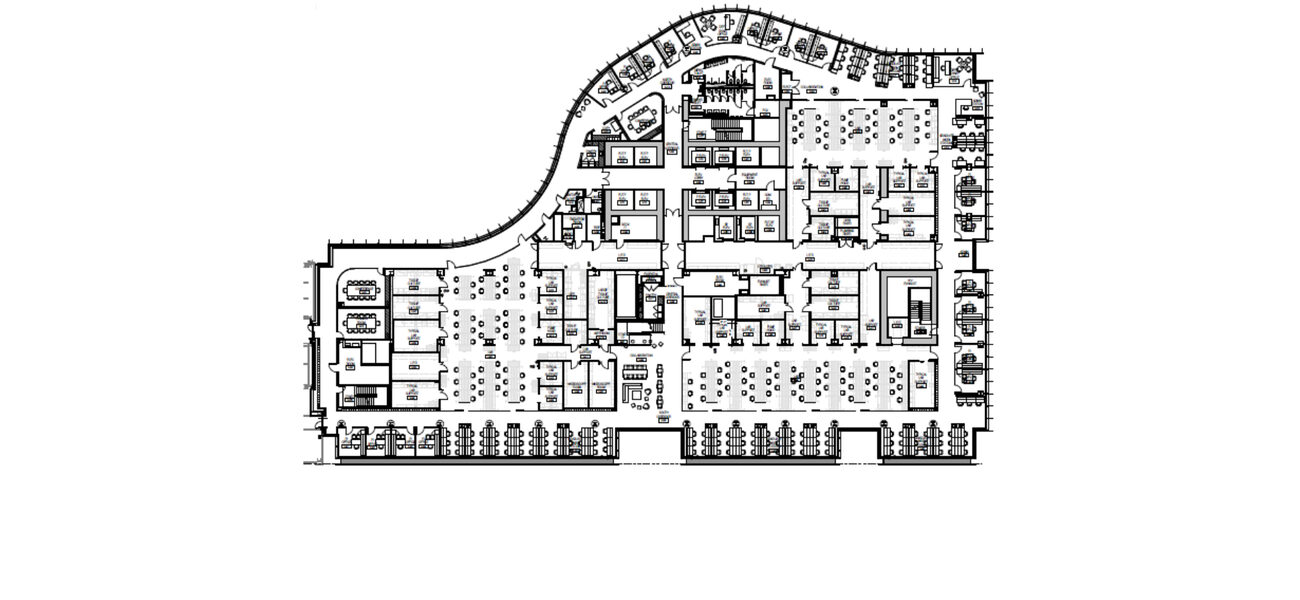

The transparent skin allows natural light to flood the building, and a layered floor plan enables it to reach deep into the labs. Offices, tech workstations, and conference rooms are arrayed along the perimeter, across the corridor from glass-walled lab blocks.

“We made an effort to avoid putting hard-walled offices where they would block light into the labs, which is why a lot of faculty offices are on the east wall and along the north wall curve, not directly opposite the labs,” says Boberg, who points out that separating the technician desks from the labs is a first for the medical school. One rationale for this departure from tradition is that allowing techs to eat and drink at their desks outside the labs encourages them to spend more time in the building.

The layout of all nine lab floors follows a consistent pattern, with all shafts and infrastructure in the same place. The repeating design does allow for some tailoring to the needs of the different organizations.

To bring the massive floorplate down to a more comfortable scale, the lab blocks are broken up into three neighborhoods, ranging from 8,000 to 12,000 sf and housing six to eight research teams each.

With specialized capabilities—BSL-3 labs and imaging equipment requiring ultra-low vibration and super-tall ceilings, for example—available elsewhere on the campus, planners focused on creating a basic lab design that is “useful for biomedical research of any variety,” according to Boberg.

“We chose not to accommodate super-sophisticated equipment in this particular building,” he continues. “The vast majority of our research can be done in an open lab with a couple of procedure rooms for tissue culture and microscopy. We don’t require many specialized spaces.”

Dropping down from the ceiling to the benches, services are limited to electrical, vacuum, and data. Natural gas is only minimally available, and compressed air is not provided. A centralized CO2 distribution scheme allows for connections to be dropped from the ceiling where needed.

“If necessary, we can remove a bench and put in a large free-standing piece of equipment in an open lab, but that doesn’t happen often,” says Boberg.

The floor plan is designed to have a very high efficiency ratio, roughly 75 percent net to gross. This was accomplished by enclosing all the space assigned to a department—benches, procedure and tissue rooms, for example—behind the door to the suite and it is thus considered part of the lab.

“This means we can claim all of the space for our federal F&A (Facilities and Administrative) rates,” says Boberg. “It allows us to put a lot of research effort into a relatively compact space.”

Shared functions like mechanical rooms and IT closets are not counted as lab real estate.

LEED Gold

Northwestern set the goal of attaining LEED Gold status for the research center from day one. Planners deployed many strategies to hit energy efficiency targets, often guided by cost/benefit analyses and the principle of “separating ‘wants’ from ‘needs,’” says Boberg.

For example, fume hoods and cold rooms are very expensive to operate, so their numbers are limited.

“Most experiments don’t need to take place in hoods or cold rooms,” he notes. “We wanted them only where they were actually being used for active research, so we asked the PIs if their work can be done in a way that is more energy efficient, such as in a deli fridge with wide sliding doors, where it’s easier to control the temperature. In most cases, the answer was ‘yes.’”

Fewer fume hoods also meant smaller ducts and fewer blowers, obviating the need to move massive air volumes through the system.

The labs and perimeter areas are supplied by ventilation systems that confine the use of single-pass air to the research space. In the labs, an Aircuity variable air-change system scales back the frequency of air changes in the absence of particulates or volatile materials, generating significant savings in heating and cooling costs.

Additional efficiency gains result from using chilled beams to provide cooling, and atomizing humidification instead of steam. Heat-recovery wheels and heat-recovery chillers lower the amount of energy needed to temper the fresh air supply. LED lighting is used throughout the building.

Solar Gain Solution

A particular challenge to energy efficiency was the south-facing exterior wall, a massive expanse of glass with a huge potential for heat gain, glare, and discomfort for occupants on that side of the building. The architects in the design competition had a mandate to address this issue.

The solution created by Perkins&Will features an intricate double-glass wall system. Between two glass walls spaced 3 feet apart is a system of perforated shades that rise and lower based on the sun’s intensity and location. The shades block the glare but not exterior views. As an additional mitigation measure, on the inside of the building are user-controlled blinds that can also be lowered if it is still too bright for occupant comfort. Vents between the floors open automatically to discharge the heat that builds up between the two walls, so the entire solar load from the southern exposure does not have to be cooled.

The scheme allows occupants who are sitting right up against the glass on the inside to be cool in the summer and warm in the winter, but as a cutting-edge solution with many high-tech moving parts, it was more challenging than expected to implement.

“We were among the first people to do something like this on such a large scale, and it has been a bit of a technological headache to get it all working,” says Boberg. “Once we settled on the overall design of a long, fully-glassed southern façade, there was not a lot we could do differently. I might encourage others to think about how it could be done more simply.”

Connections

Describing the location of the new facility as “right at the nexus of both the clinical and the research buildings of the campus,” Boberg emphasizes that each of its nine lab floors is connected to the adjacent Robert H. Lurie Research Center.

“This allows for the 40,000-sf floorplates of the new building to connect to the 20,000-sf floorplates of Lurie to create an even larger footprint of intermingling researchers,” he says.

On its second floor, the new research facility is also linked to the network of enclosed bridges that connects 13 buildings and two parking ramps on the campus.

“A lot of scientists go back and forth between clinics and research labs. Our ‘superhighway’ makes it easier for them to do that without coats and umbrellas.”

Connections among occupants inside are equally important for a building that was “designed to be a vibrant hub to bring together world-class physicians, scientists, and engineers, to form new connections and accelerate discovery in the study of cancer, heart disease, and neurodegenerative disorders,” says Boberg. “Nobody does science in isolation anymore.”

On every other floor is a two-story break space/collaboration area outfitted with comfortable furniture. Light-filled from the southern exposure, these spaces are equipped with a writable surface, large screen, and presentation capabilities, and are often used for impromptu lab meetings and informal gatherings. They are also very popular at lunch time.

Attractive outdoor landscaping, a “must” for neighborhood association approval, creates a soothing oasis for occupants seeking fresh air and a tranquil setting apart from the bustle of the city.

Preparing for the Future

Having launched its methodical expansion program in the 1990s, the medical school’s growth has skyrocketed over the past decade. According to Boberg, no other U.S. medical school has grown faster over the past 30 years.

There is already talk of the need for more research space. The new building was designed to accommodate the extra weight of the vertical addition, with strengthened structural columns, caissons that anchor into the ground, and wind shear support at its core. It also has enough room for elevator shafts and the service risers that will allow services to reach the upper floors at a future date.

In addition, it complies with city permitting requirements that mandate two floors of unoccupied space between the occupied area and new construction, “so if an I-beam gets dropped, something will stop it before it hits someone,” explains Boberg. To avoid having to displace occupants, planners allocated the top four levels (which include two large mezzanines) of the first phase for mechanical equipment. These floors will also serve as a buffer helping to absorb vibration that is inevitable in construction.

Even with these preparations, however, an announcement on timing of the addition is not expected in the near future. When planning for the research facility got underway in 2012, construction costs were inarguably lower. In light of today’s rapidly escalating numbers, Boberg says it’s impossible to know if the calculation of not building shell space still works out to Northwestern’s advantage.

“Nobody knows what’s coming,” he says. “Plenty of people believe we’re in a bubble, and costs will come back down once supply chain issues resolve. One of the hardest things is modeling the extent of escalation in 2025 vs. 2030, and how many floors to build out initially. There is obviously concern, and it will be a factor in whatever decision is ultimately made.”

What is certain is that the building’s next-generation design has played a significant role in propelling the school’s research funding to more than $640 million—up from under $300 million when planning started—well ahead of schedule.

“Our dean brought the vision and the ability to marshal the resources necessary to execute through philanthropy and negotiations with the university and our hospital partners,” says Boberg. “The faculty works really hard at getting and keeping grants, and the dean’s office gets them what they need. Facilities, mentoring, information infrastructure, vision—all these things work together.

“The building is a beautiful environment to work in and is a big help recruiting rock star talent and lab staff,” he continues. “Once you start to pull together a critical mass of investigators in a particular field, like our huge neuroscience program, for example, others want to come and play. The more of those we have, the easier it is to get the best people to join us.”

By Nicole Zaro Stahl