While creating generic/flexible lab spaces that can be adapted to a variety of different research needs continues to be the preferred approach—especially in higher education buildings—there is also a growing need for highly specialized lab and support facilities designed for very specific types of research. As a result, facility designers are increasingly tasked with balancing the demand for both open generic/flexible labs and specialized lab spaces in a single building with the added challenge of improving energy efficiency, sustainability, and operating costs.

One example of this trend is the Yale Science Building (YSB), a five-story, 277,500-sf academic research facility designed by Stantec as architect of record in collaboration with Pelli Clarke Pelli. The new building, which opened in fall 2019, features flexible/modular lab spaces designed for a wide range of biology, physics, biophysics, and biochemistry disciplines. It also houses specialized research spaces that include aquatics labs, insect labs, an imaging suite, and a plant lab with a rooftop greenhouse.

“There’s a lot of interest in creating these open, generic/flexible lab spaces,” says Michael Reagan, science and technology lead at Stantec. “They continue to make a lot of sense to a lot of people. But it’s important to recognize that we’re not going to be able to solve everything with generic and flexible. Depending on the science, you may also need some specialized spaces. And if predictions are correct, you may need more of that in the future. But we can still achieve energy-efficient spaces with generic laboratories and even some of the specialty spaces, if we design them correctly.”

Most of the YSB’s generic/flexible lab spaces are located on four floors with a repeatable modular floorplate. Many of these generic labs are devoted to life science and biology disciplines that require lots of wet labs and instrumentation. A quantitative biology lab (called “QBio”) on the main floor is designed as a flexible space that can go from dry computational labs to wet labs. The building also supports chemical synthesis work, which requires more fume hoods than would normally be found in a life science building. Specialized spaces include a greenhouse, a vivarium, aquaria, insectaries, and vibration-isolated physics laboratories. There are also molecular biophysics and biochemistry labs that house lasers and other sensitive instruments.

“You can do a lot of the heavy lifting with generic labs, but you still need some specialty support spaces—meaning cold rooms, warm rooms, microscopy, or other spaces that might need to be darkened, vibration-isolated, sterile, or require separate air pressure,” says Reagan.

Flexible/Generic Spaces

The floors dedicated to generic/flexible space consist of a repeatable modular layout of laboratories and laboratory support. Adaptability is enabled by movable benches that are all plugged into the ceiling. This configuration allows benches to be removed simply by unplugging them. Elements that are more difficult to move, such as sinks and fume hoods, are located on the perimeter.

“This makes it easy to reassign researchers. If you need to put in some additional equipment, the benches can be removed, and you can put a biosafety cabinet or freezers in the middle of a lab,” says Reagan.

Another flexibility feature of YSB’s design is the ability to convert some of the lab space into support space as needed. In fact, researchers have already identified the need for more support space, even though the building has been occupied for a short time. The QBio computational lab also has a generic/flexible design with the needed lab-support ratio to become a chemistry or biology lab in the future if necessary. The area of the building dedicated to plant science also features moveable benches that are situated perpendicular to the exterior walls with lots of natural daylight and floorspace for adding equipment.

“That same layout can be adapted to other sciences with different types of instrumentation, but the important thing is that it can also accommodate chemistry,” says Reagan.

Flexible Specialty Spaces

While specialized facilities are crucial for supporting specific research needs, there can still be some degree of flexibility in their design. For example, a certain amount of flexibility can be achieved with vivarium housing rooms and prep rooms by designing them to accommodate either animal housing or prep.

While the aquarium spaces were created for housing zebrafish, the tanks and racking systems can be changed to house axolotl—a species of Mexican salamander—or other types of amphibians. Likewise, the facility’s imaging core was built with light-proof doors and vibration sensitivity, but it also has internal spaces that can support several different types of electron microscopy instruments that can be swapped out based on need. There is also a plant potting area on the roof with adjacent environmentally controlled growth chambers for different plants.

“The flexibility in those spaces comes from the ability to alter the temperature and humidity in each one of those growth chambers,” says Shawn Maley, senior associate at Stantec. “This allows researchers to work on growing plants in different climates and conditions with lighting controls that allow them to alter the diurnal systems.”

The insectary contains a BSL-3 facility (used to study the Zika virus), where mosquitoes are isolated in containment facilities. There are also ACL-2 and ACL-3 (Arthropod Containment Level) spaces with environmental chambers where researchers can control the temperature and humidity to study the rearing of insects in different climates and conditions.

Energy Efficiency and Flexibility

Among the many challenges in cost-effectively creating a building with generic/flexible open labs combined with vivarium, microscopy, physics and other specialized spaces is designing a robust HVAC and engineering system that can provide generic/flexible functionality yet still support specialty research requirements as the building evolves.

“The criterion that every university places on us, is that they want to do all of this and also use less energy,” says Paul Pohlod, principal at Stantec. “We implemented some strategies on this project that helped us balance the building’s Energy Use Index to meet their goals while still giving them a lot of flexibility.”

One of those strategies was using chilled beams in the open labs and combining them with an extended plenum and oversized ductwork. These HVAC system features, in combination with targeted ventilation and system setbacks during unoccupied modes, ultimately provided a 33 percent reduction in air change rates over a more traditional HVAC system, and the actual performance is turning out to be up to 25 percent more efficient than the university’s target.

“We took a careful look at the vivarium to understand how many air changes were needed to maintain a safe and appropriate facility. An interesting strategy we used included oversized ductwork over the entire extent of the generic open labs to allow us to be able to plug in high-air-intensive spaces as needed.”

“This approach offered a number of benefits,” says Reagan. “Normally, a duct necks down; but in this case, we just made the duct the same size all the way down the line. In addition to requiring less labor because there are fewer fittings, there is also less static pressure—because every fitting creates static pressure—which means it’s quieter and the fan is smaller. So that one simple thing snowballed into all these other advantages. Sure, it takes a little more sheet metal up front, but you save it back in a couple years through reduced required fan power.”

Modular Prefabrication

Another strategy that delivered increased savings and flexibility was leveraging the advantages of modular prefabrication during the design and planning phases.

“When we started the Yale Science Building project, we began looking at what we could do with prefab,” says Maley. “Based on the layout, full-scale 3D modular prefab was not going to work. But repeating modules—both multi-trade and single-trade—was perfect for the situation.”

Multi-trade prefabrication is a construction process where standardized frame assemblies are created offsite so all the various support services can be prepackaged into them. Then they are quickly assembled onsite by specialized teams. This results in a high level of consistency and repeatability—down to the same location of the stickers and valves in every lab, on every floor.

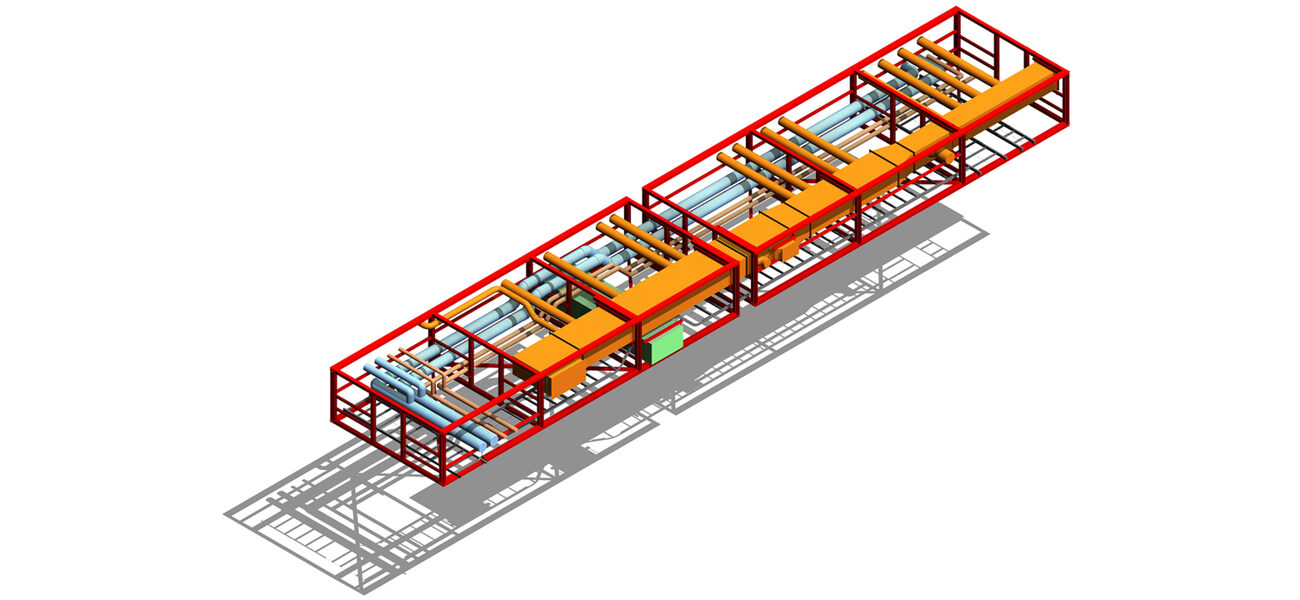

“During the design process, we developed a total of 86 assemblies in the building. While the steel was going up, those assemblies were being made offsite with all the ductwork, hydronic piping, high-purity piping, chilled water, fire protection, and cable trays,” says Maley.

At the same time these multi-trade support assemblies were being built, the single trade assemblies—like the building’s multi-floor risers—were also being built to support generic flexibility across the entire building so that everything was interchangeable.

“Then the contractor came to us and said, ‘Hey, I want to do the main 18-inch chilled water and 12-inch steam lines to the building as one prefab thing.’ That was when I realized I wasn’t thinking big enough as an architect. I mean, these things are amazing. They’re 90 feet long. We brought them in over a weekend and slid them into the building using a tower crane. Overall, it took the same amount of time to construct them, but we saved 960 onsite man-hours. To Yale, that was 960 hours someone wasn’t disrupting the neighborhood, the students, or the education.”

While it takes more time to plan and coordinate an offsite modular prefabrication process at this scale, it can significantly improve both the overall safety and construction quality by ensuring that a rigorous quality control processes happens in the fabrication facility prior to installation. This means that 90 percent of the connections are pressure tested to make sure they work before they are taken to the site and installed by dedicated teams.

“As for the schedule, yes, it takes longer to coordinate. It took two months to build one floor offsite. But at the same time the tower is going up with the steel, we are building the modular sections offsite. So, the actual schedule savings was like two or two and a half months. Plus, we were able to install a complete floor in six days. From that point of view, the benefits were incredible,” says Maley.

“The commissioning agent indicated that the prefabricated unit’s repetitive and consistent locations for shutoff valves, dampers, and other components, made it easier for them to access and adjust the system as they worked their way through the building,” adds Maley. “Due to the ease of access, we anticipate the building will be easier to maintain through the life of the building.”

“I think one of the big take home points from this project is that generic/flexible labs continue to be the best way to go in these kinds of facilities, but there are ways we can take advantage of this approach by looking at things like prefabrication. Another interesting point is that the pandemic hit after we did all of this, but that project would not have been shut down if the pandemic hit while it was being constructed because of how the prefabrication process worked,” says Reagan.

By Johnathon Allen