The newly renovated Robert A. Welch Hall lays the groundwork to transform the way science is taught and done at the University of Texas, Austin, to move from siloed departments to transdisciplinary research that focuses on emerging fields that occur at the interfaces of traditional core science departments. While the sciences had been almost entirely housed in separate single-department buildings, the College of Natural Science’s master plan calls for more program-based facilities. The renovation infuses the building with light and increases its research capacity by 30 percent.

Welch Hall is a conglomeration of four buildings: two wings built in 1929, which were renovated in 2015; a 1961 wing; and a 1978 wing. This project entails the renovation of the five-story, 250,000-sf 1978 wing into a low-fume-hood-dense chemistry hub of classrooms and research labs.

The project was identified as the highest priority in a plan to revitalize the central core of the campus, home to the College of Natural Sciences. It is one of the largest colleges of natural sciences in the country, with 1,200 staff, 700 faculty, 11,000 undergraduates, and 1,300 graduate students occupying 1.2 million sf in 15 buildings.

More than 10,000 undergraduates pass through the grand concourse of Welch Hall every day. Previously, it was a dark and uninviting space, with very little natural light, very few windows, and dark brick floors. The hallways leading to the labs were dark and dingy. The concourse has been transformed into a campus destination that serves as a student commons, with diverse amenities that include study areas, collaborative space, social space, a café, and space for teaching assistants.

The building contained many steeply-tiered general-purpose lecture halls with capacities of 300-500 students. Some of them were refurbished with new HVAC and lighting, while others were transformed into collaborative tiered classrooms and flat-floor active learning classrooms. The active learning classrooms are provided with glass marker boards, projectors, and screens on walls, allowing for significant flexibility in use and layout. While the classroom seating capacity overall decreased from 1,805 to 1,451, the new classroom spaces better support the experiential learning pedagogy that is a hallmark of the College of Natural Sciences.

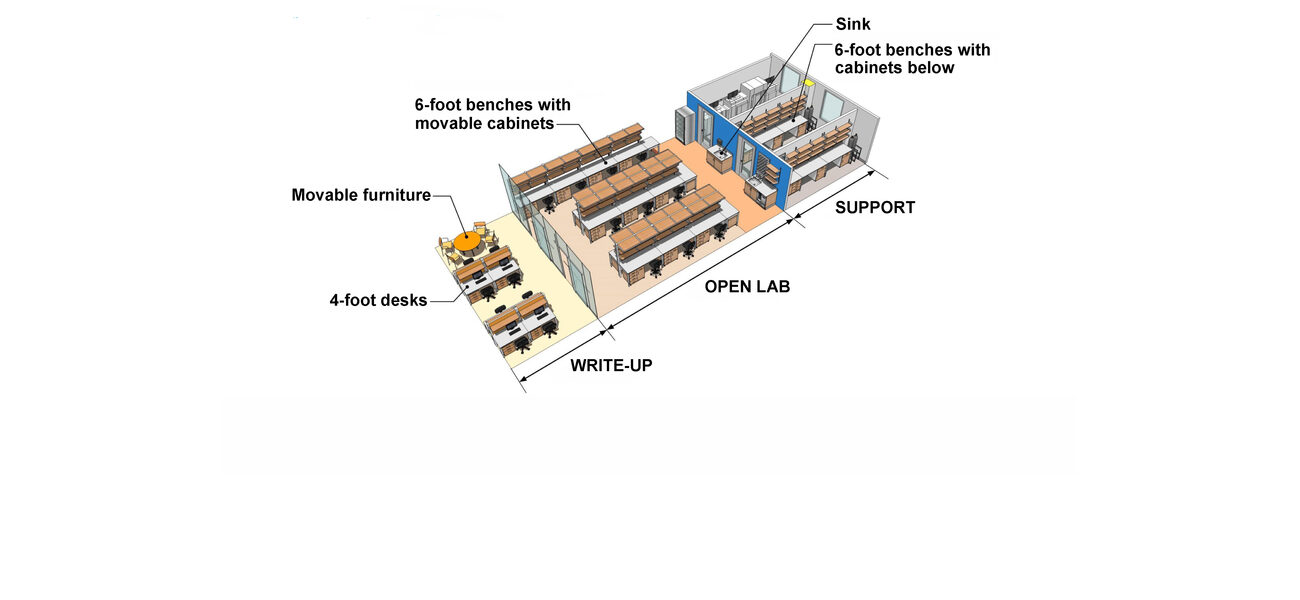

The research labs, located on the top three floors, originally consisted of cellular labs, many of which were unchanged since 1978. The floor plate was opened up to make the space more flexible, with lab suites containing write-up zones separated from the labs by sliding glass doors. The lab spaces could be densified—enough for 54 additional research positions—in part because additional informal collaborative spaces were pulled outside the security zone of the lab suites. Natural light from floor-to-ceiling windows fills the floor plate, while existing elevator shafts and stairs break up the space.

Less visible though equally important were the upgrades to the building’s MEP systems, which were undersized and at the end of their useful life. Lab exhaust fed into six vertical shafts to exhaust fans on the roof installed in 1997. Supply air was drawn from two air handling units in the basement. A third unit in the basement served the first two floors, which contain the classrooms. A greenhouse on the roof was moved to an adjacent building to make room to expand the mechanical system from above, and new AHUs were installed in the basement, so that it feeds both from above and below, using the existing shafts.

| Organization | Project Role |

|---|---|

|

Payette

|

Architect

|

|

STG Design

|

Associate Architect

|

|

The Beck Group

|

Construction Manager

|

|

Shah Smith & Associates

|

MEP Engineer

|

|

Garza EMC

|

Civil Engineer

|

|

Datum Gojer Engineers

|

Structural Engineer

|

|

Ten Eyck Landscape Architects

|

Landscape Architect

|

|

Datacom Design Group

|

Audio/Visual

|

|

Jensen Hughes

|

Code Consultant / FP Engineer

|

|

Lonestar Environmental Services

|

Hazardous Materials

|

|

Lam Partners Inc.

|

Lighting Design

|

|

CPP, Inc.

|

Wind Engineering

|