To work effectively with huge amounts of complex research data requires not just computational efficiencies, but team-centered facility design. The Allen Institute’s new 270,000-sf Seattle facility implements an innovative floor plan to integrate lab space, office space, meeting space, natural lighting, air flow—and most importantly, movement of people. “What we have done with our new research building is to take the basic research model and scale it up to a more team-oriented environment,” says Paul Wohnoutka, senior director of operations. And it supports this new environment with several inventive energy-saving mechanical systems.

Scaling up, in the context of the extremely complex biology problems these teams are working with, means accommodating larger teams, many different disciplines, and a strong focus on planning, goals, and deadlines. Efficient circulation is key. Everything from the location of the offices and labs to the traffic patterns in and around the workspaces is designed to get you where you need to go quickly, and to have everything you need close by.

For example, a vertical vivarium design places a vivarium suite on each floor, with an animal holding room and space for behavioral training and surgical procedures. Inner and outer circulation loops allow staff easy access to all the labs, and there are plenty of spaces for impromptu meetings with colleagues. Corridors and a central atrium are designed to bring natural light all the way through the labs, and conference rooms overlooking the lake provide an enjoyable meeting environment.

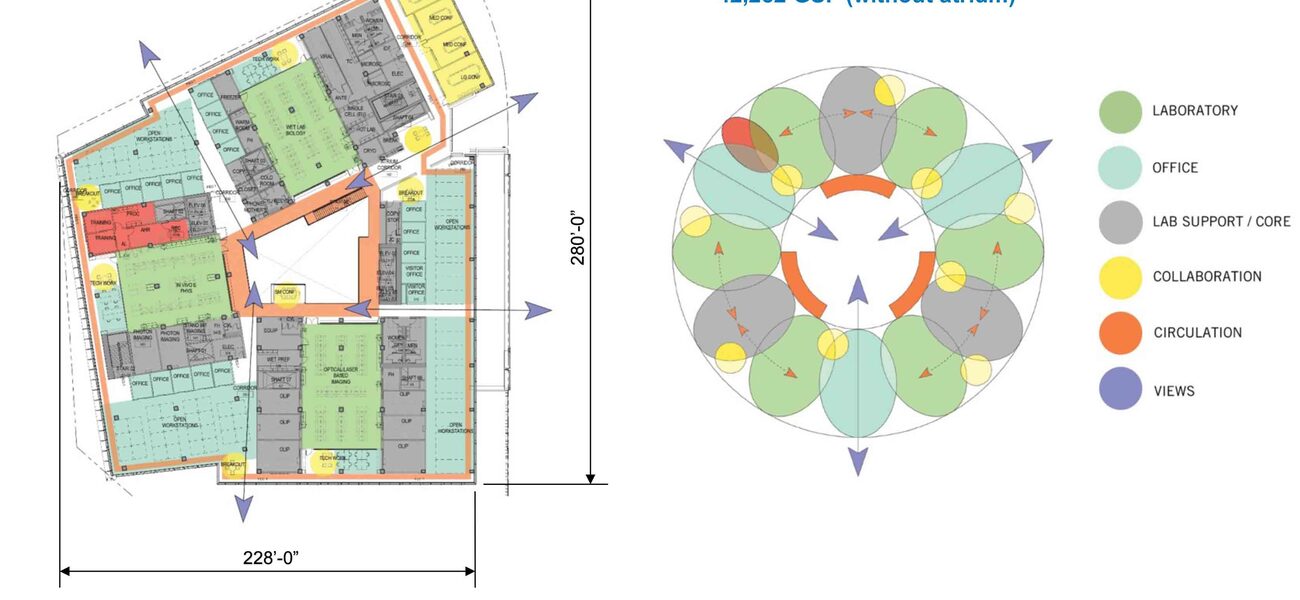

Petal Layout

While many ideas figured into the visioning process for the new facility—including LEED gold certification, wellness, respect for the neighborhood, and maximizing efficiency wherever possible—the process centered around supporting a culture of team-based, collaborative science. The main goal was that as a research facility, the labs should stand out, and that the occupants should feel a part of all of the functions in the building. To accomplish this, the design team came up with a “petal” layout concept, in which labs, offices, and meeting spaces are melded together to maximize natural light and views throughout, and to create efficient circulation.

On each floor, three office neighborhoods are separated by three laboratory areas, each representing a petal. Within the office petals, the open office areas are along the exterior glazing, giving most employees as much natural light as possible. Each lab petal, while highly adjustable, has a subtle theme. For example, in the south petal of the third floor are Class 4 laser-based imaging rooms, customized with additional lighting, power, and thermal controls. To accommodate laser work on an isolation table, structures are set up to allow scientists to hang equipment overhead. The north petal has tissue culture rooms; and the west petal includes a vivarium suite to support the lab work on the floor, connected via elevator to the core vivarium.

The inner and outer loops and the radial corridors demarking each petal allow easy movement throughout the labs, offices, and conference rooms. Spectacular sight lines through the space and the location of seating and meeting areas encourage collaboration with colleagues.

Big Data and Uninterrupted Power

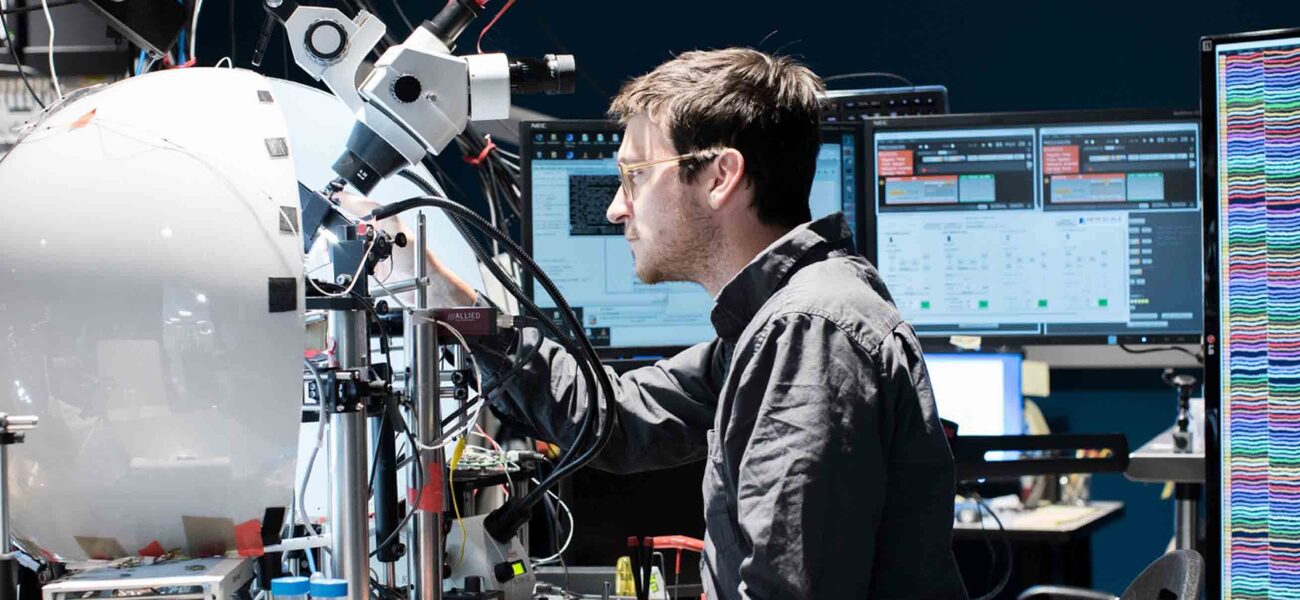

Much of the research work at the Allen Institute is about the brain. “Our scientists would like to break down the entire human brain into its components, cells, connections, and bring that to computation,” says Wohnoutka. This involves a range of disciplines, from microscopy, physiology, and molecular biology, to data modeling, software development, and engineering.

One of the projects seeks to apply a 3D modeling concept to brain structure. We have seen how CAD and BIM applications can create 3D models of buildings, and allow a user to move through the building virtually. At the Allen Institute, scientists are working on creating a 3D model of the mechanics and infrastructure of a piece of the brain, by using specially modified electron microscopes to map a 1-millimeter cube of brain tissue.

“There are 100,000 neurons and 1 billion connection points in that 1-millimeter cube,” Wohnoutka explains. “Our scientist want to fly through this brain tissue with similar features that facility design teams have when using CAD and BIM technologies; a pretty big task to fly through!”

And this amounts to a lot of data and a lot of processing. The Allen Institute generates up to 2.5 petabytes of data—2,500 terabytes—in a single year. Imaging data is processed 24 hours a day, and this means that a consistent, uninterrupted power supply is critical. Typically UPS requirements to manage power during a municipal power outage are supplied by battery backups for the short term, and generators for longer term. But battery backup systems come at a cost: the need to handle, ventilate, and eventually replace expensive batteries. To eliminate these drawbacks, the data center uses new flywheel technology. The flywheel backup systems provide up to 45 seconds of uninterrupted power, allowing time for a dual generator pack to kick in.

Energy Conservation

All that data processing means a lot of processors and a lot of heat generation. Hot and cold aisle technology facilitates capturing the waste heat. It is then repurposed to produce humidity for the vivarium space.

Among the more challenging energy conservation objectives was to implement LED lighting in place of traditional fluorescent lighting systems. The design called for LED lighting throughout: in the labs, in the offices, and on the exterior of the building. A major concern was lighting for the animal holding rooms, which at move-in would house 4,000 cages. With fluorescent lighting being the norm, the engineering team couldn’t find an example of a rodent vivarium using LED lighting throughout, so it was necessary to design a test of the planned setup. The team converted a fluorescent lit holding room in the old facility to LED lighting, so that vivarium and scientific personnel could be convinced LED lighting had no impact on the research animals. Not only did they find no noticeable change in moving away from fluorescents, but with LED lighting, the scientists in the lab were able to mimic a natural light cycle with periods of dimming, which was not possible with the typical fluorescent lighting systems.

Aircuity® demand-based air controls offered another major improvement in energy use. By implementing demand-based systems in most of the labs, the engineers were able to reduce air changes by about one-third, from an average of 15 air changes per hour down to 10 ACH.

Team-Orientated Environment

Especially in the current competitive market, providing a rewarding work environment is critical. To encourage greater interaction and creativity, to eliminate silos, and to support the technical and quality-of-life demands of the new generation of scientists requires a focus on effective team organization.

“We do not organize people by department or function,” says Wohnoutka. “We want to create a vibrant environment where everybody is treated well, and everybody feels like they have been respected and heard.” The Allen Institute does this in part by turning the traditional department concept on its head, abandoning the arrangement of clustering people in each department together and instead spreading executives and teams from different groups around the entire floor. “We feel like this encourages movement throughout the building and interaction to get things done,” explains Wohnoutka.

Another way to foster cross-department interaction among employees is to encourage mingling. On the sixth floor is an open café area overlooking the water. Instead of sitting at your desk and getting up once in a while to grab a cup of coffee in the corner and sit back down, when it’s time for a break or a meal you go upstairs and eat with your coworkers.

And if you want to ride your bike to work—and more than 20 percent of Allen Institute employees do—you will enjoy having bike facilities designed to support your green transportation.

Back in 2003, the institute was located in a 15,000-sf office in Freemont. Wohnoutka recalls that environment: “There was very little to no operational entity thought at the time. It was just, you are a software developer, you are an engineer, you are a scientist, you are all sitting together, you are all working in this one lab.” The new, 270,000-sf lab now supports a staff of 470, but preserves that same theme through carefully designed intermingling of company assets from the labs and offices to the people working in them.

By Todd Woofenden