A new approach to space planning based on Lean design concepts improves space utilization processes and helps reduce building and operating expenses for academic, research, and healthcare facilities by achieving maximum efficiency with minimum construction.

The challenge is defining optimal use during the initial planning phase of a project and maintaining flexibility throughout the lifetime of the building. “There is an operational component to Lean in terms of how to design space, what to design, and how you put it together in order to have very efficient operation throughout its lifecycle, not just during construction,” says Tom Demko, a principal with Stantec Architecture.

Changing the Planning Paradigms

Lean processes can improve the overall performance of facilities, whether the project involves academic, research, or medical environments. “For us, Lean has become a way to manage the work process. It has to do with managing waste and optimizing resources, and helping our clients apply these principles to their projects,” says Demko.

This approach changes the way buildings are structured, with an emphasis on spending time up front researching facility use and scheduling patterns. This data helps determine the distribution of existing resources or new facilities. “You have the most impact on a project at the beginning by making the right choice, by designing the right project. You can build a project very effectively and cheaply, but it is all lost money if you build the wrong project,” says Demko.

Lean principles readily apply to any large-scale building project. Alex Wing, who oversees Stantec’s academic and university building projects, says Stantec encourages clients to discuss the best use of available assets and rethink how to program space and deliver the product. “It’s not just about planning space, it’s about helping people rethink how their organizations work,” he says.

Optimizing Space for the Learning Environment

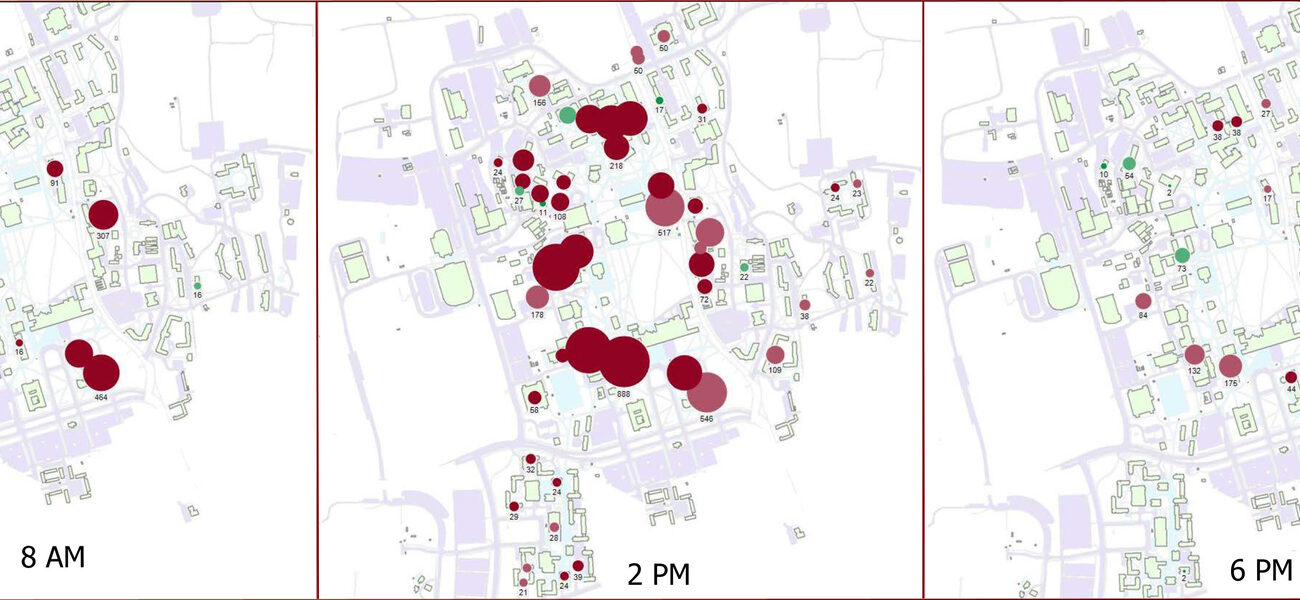

Incorporating Lean concepts in space planning for the academic environment means understanding how inventory and curriculum relate to scheduling. Up-front schedule analysis to remove some of the peaks and valleys in the schedule will pay off at project completion, says Wing. Sometimes creatively rearranging inventory and curriculum achieves the Leanest use of space without additional construction. For instance, a utilization study of classroom schedules may show that students in a specific course experience peak class size at 10:15 on a Tuesday. If some classes are rescheduled, moved to different rooms, or taught by another faculty member, it may be possible to teach a course to the same number of students using fewer classrooms. “By doing schedule analysis well, you can really reduce the amount of space that you need. Ultimately, we want to determine how best to distribute the use of facilities so we don’t build more than we need to,” says Wing.

The methodology for optimizing the space utilization at higher education institutions includes:

1. Set a baseline. Start with inventory analysis, in terms of available room capacity, seating arrangements, and instructional technology.

2. Establish room utilization targets based on inventory measurements, taking into account the percentage of time classrooms and lecture halls are occupied vs. available time. “How many people should be sitting in this space, and how often should the space be scheduled?” says Wing. For instance, if a classroom or lecture hall has relatively high use, it may be less important to fill the space to capacity. In contrast, more expensive spaces like labs and specialized areas will have higher fill rates but might be scheduled for use less frequently.

3. Establish a needs assessment based on the curriculum to determine how much space is necessary for the given educational program. This includes credit-hour demands for a typical student in the program, projected enrollment, and time spent in various venues for each credit.

Planning for Clinical Care Facilities

Lean processes can also help physicians' offices, clinics, and hospitals to manage space more efficiently. “There are ways to manage clinical resources more effectively without just building more space, including utilization studies, delivering healthcare at fewer dollars per square foot, and looking at scheduling flow. The best way to understand that is through Lean concepts,” says Demko, who oversees healthcare projects for Stantec.

Large healthcare institutions housing multiple disciplines may benefit from implementing flexible schedules that alternate clinic days and surgery days. These “flex clinics,” along with creative scheduling, create opportunities to use space more efficiently. On the days some staff have scheduled surgeries, another group can use the clinic. “If you have limited square feet of clinic space, on some days the space might be occupied by large groups of physicians and on off days used by physicians with smaller practices. Instead of every physician thinking of clinic space as designated space that may lie fallow on a surgery day, the space can be scheduled differently,” says Demko.

As with academic institutions, a key component to success in a healthcare project is convincing clients to think about scheduling before design and construction. Often these discussions require a cultural shift. “Lean is most successful when an institution can implement it early in the process. Ultimately, everyone benefits from the savings. In a healthcare facility, this means avoided cost-cutting measures, happier patients, and a more efficient institution,” says Demko.

He used the example of a cardiology group with 12 physicians each requesting three exam rooms on the same day, resulting in these rooms sitting empty the remaining weekdays. Adherence to this schedule creates a cost to the institution in terms of lost efficiency. The new design included 16 exam rooms and a new scheduling model with physicians rotating their in-office days, results in increased efficiency and cost savings. “When you design the right-sized space and support the design with scheduling and data models, it will function efficiently, and you are not building unused inventory,” says Demko. “Clients understand that when you build less space, you have lower operating costs, and that savings can be devoted to other areas. Really, what we are trying to do with Lean is change our model of design from something that is emotionally driven to one that is analysis or data driven, where we can demonstrate quantifiably what is the most appropriate building solution.”

By Mary Beth Rohde

This report is based on a presentation Wing and Demko gave at the Tradeline 2013 Lean Facility Lifecycle Conference.