Cage and rack washers, while not the industry standard for large-scale animal cage washing, are more efficient and cost-effective to operate than tunnel washers, according to a study by two Boston architects with decades of experience designing animal facilities. Their research shows that the long-term operating savings compensates for the higher up-front cost.

Escalating costs and environmental impact associated with cage washing—square footage, energy, and labor—prompted Payette architects Jeffrey Zynda and Michael Hinchcliffe to take a new look at equipment and operational solutions, and analyze a number of variables directly related to cost and resource/energy efficiency. They advocate that the initial capital costs associated with a successful redesign or installation of a cage-washing facility are eclipsed by the longer-term savings—particularly with energy becoming increasingly expensive.

Continuous Conveyor Versus Batch Washing

The two primary processes utilize tunnel washers or cage and rack washers, although many labs use a combination of both types of equipment. Tunnel washing is a hydro-sprayed, conveyor belt process, usually staffed at both ends. The tunnel washer is like a car wash, with cages continuously fed into the machine and removed when clean. High-ventilation air-change rates continuously vent steam and maintain tolerable temperatures for workers. As one might expect, tunnel washing requires a large equipment and operations footprint, and consumes considerable energy and resources. Yet it is virtually the standard in labs that handle a high volume of cages.

Cage and rack washers, alternatively, are a somewhat smaller apparatus. Rather than requiring a continuous feed of cages, they operate on a batch process, a distinction that proves central to Zynda and Hinchcliffe’s research.

“With cage washing, once you load the machine, you can go and do other things, whether that is prepping the next batch of caging, uncarting the last set, or another activity that’s unrelated," says Zynda. "In other words, the single person operating the cage and rack washer is not chained to the task at hand.” Additionally, the smaller cage- and rack-wash equipment’s batch processing consumes less water, steam, and electricity, and the room where the washer operates does not demand the continuous ventilation required by tunnel washing.

Chris Cosgrove, consultant to animal care at the Memorial University of Newfoundland, says that the batch process immediately makes cage and rack washing less HVAC-demanding than tunnel washing. “The difference is that a rack washer will exhaust only one or two minutes during its cycle. A tunnel washer not only exhausts continuously, it also draws air into the machine from both sides, which makes balancing the pressure differential between the clean and dirty side more difficult.”

Although both processes have the same throughput capacity, the batch process provides substantial energy savings over continuous process.

“Assuming an average tunnel washer pulls 1,500 cubic square meters per minute, over an hour, that’s 90,000 cubic feet of exhaust,” says Cosgrove. “Whereas a rack washer that requires the same 1,500—and usually they don’t—with a 10-minute cycle, you might run six cycles per hour. With a two minute exhaust phase each, that’s still only 12 minutes, or 18,000 cubic feet.”

Another potential advantage of cage and rack washers, according to Cosgrove, is that some models have gaskets built into their doors to minimize air pulled into the unit, which minimizes risk of cross-contamination.

Payette Study and its Findings

When Hinchcliffe and Zynda began their study, they had just completed a post-occupancy evaluation of the design at Utah State University that revealed the potential for significant improvements in the cage wash operations through application of Lean design principles to this process. Shortly after this study, they were part of a grant application for a large state institution in the Northeast, and they focused on analyzing energy and cost savings.

“The centralized cage wash facility was the biggest energy consumer on the entire campus,” with its two tunnel washers (one for cages and one for bottles), rack washer, and double-sided autoclave (for pre-wash sterilization), says Hinchcliffe. “From a planning standpoint, one of the things that made the most sense was to analyze the peak load and average it out on a daily basis.”

The peak flows at this facility were three days a week—Tuesday, Wednesday, and Thursday—making tunnel washers an appealing choice because labor hours, it was thought, could be most effectively allocated to those days.

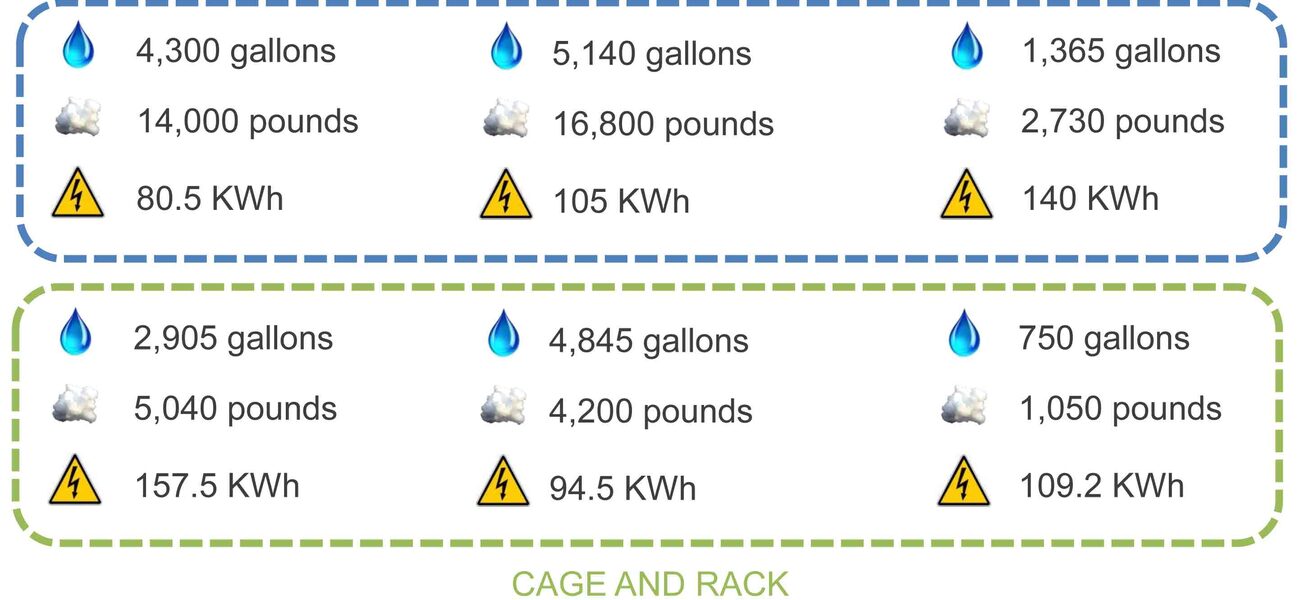

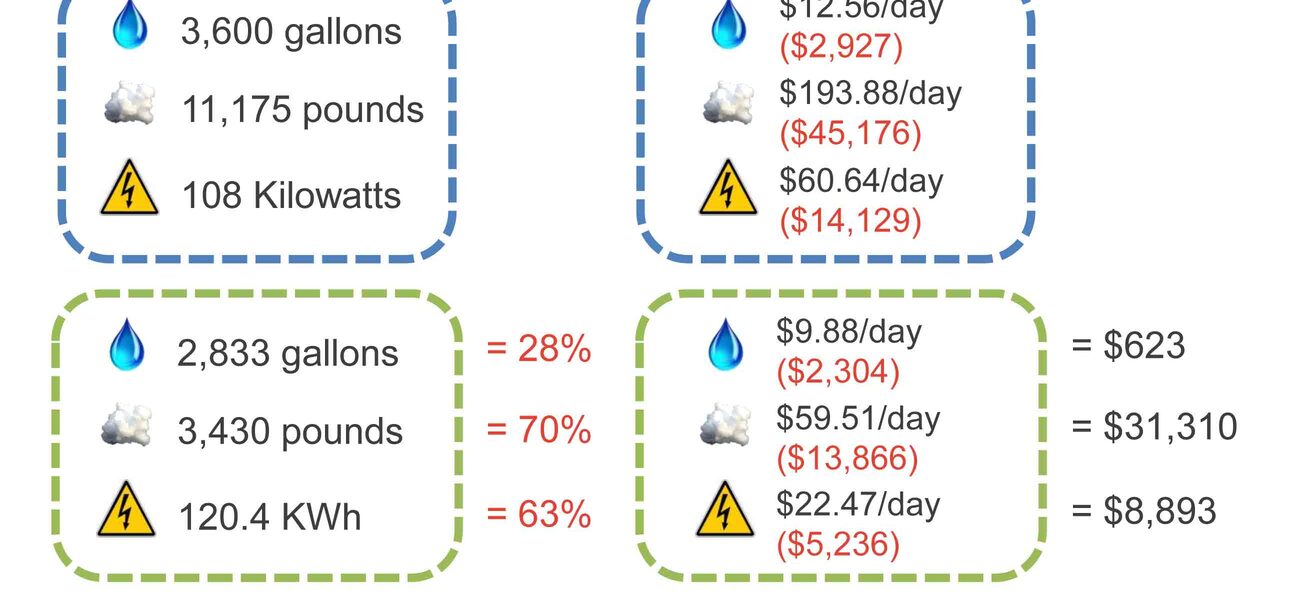

Zynda and Hinchcliffe identified three top manufacturers of both tunnel washers and cage and rack washers, and gathered data on the amount of water, steam, and electricity required to handle 10,000 cages across one week for each type of equipment/process. Their findings? “Daily consumption was an order of magnitude less for water, steam, and electricity for cage and rack washers,” Zynda says. “Between 4,800 gallons of water (for tunnel washers) and 750 gallons (for cage and rack washers); 5,000 pounds of steam and 1,000 pounds; and anywhere from 95 kilowatt hours up to 160 kilowatt hours (with tunnel washers using slightly less electricity on average than some cage and rack washers).”

In tandem, they examined local costs for each of these three utilities. They noted that such costs might vary by location if this same study were undertaken elsewhere, but they were able to derive an average operational cost for both tunnel washers and cage and rack washers. While both processes can handle the same capacity on a daily throughput basis, the cost of the utilities consumed was significantly less for cage and rack washers. For the same load of 10,000 cages, tunnel washers consumed approximately 30 percent more water, 70 percent more steam, and 60 percent more electricity. On an annual basis, says Zynda, “there is an estimated $40,000 in theoretical savings.”

Even More Savings With Automation

Further savings can be derived from re-examining staffing. Because of the batch process involved in cage and rack washing versus the continuous-feed conveyor of a tunnel washer, “For every tunnel washer that is replaced by a cage and rack washer, you can potentially eliminate one full-time position,” says Zynda. He indicates that this theoretical “elimination” of a position could be a re-tasking of that individual’s workload to improve overall operational efficiency.

In addition to the manpower, energy, and overall cost savings, the significantly smaller footprint of the cage and rack washer frees up space for other uses, such as much-needed storage or swing space. Furthermore, the idea of robotics and robotic automation is not far in the future, says Hinchcliffe. “VA Hospitals are using robots to deliver pharmacy goods and samples,” he says.

Automation has less of an economic benefit for facilities washing fewer than 1,000 cages, but Zynda and Hinchcliffe feel the trend for larger operations is toward more automation, not less. While robots have typically been utilized only for tunnel washers in the past, new technologies have evolved that now enable automation for either kind of washer. One application the pair anticipates is the use of robotic vehicles to reduce the need for human employees transporting cages from one part of a facility to another.

Conclusions

Zynda and Hinchcliffe urge facility owners to focus on the long-term potential savings: A facility that relies on cage and rack washers would save 848,000 gallons of water, 2.935 million pounds of steam, and 22,000 kilowatts of electricity annually. This translates to an estimated operational direct utility cost savings of $2,960, $51,000, and $1,760 respectively, for an annual total savings of nearly $56,000.

“On average, the operational costs of a vivarium will equal the initial capital investment in 10-15 years,” says Zynda. “Decision-makers need to think beyond first costs. Right now there is an increasing burden on researchers to justify their bench space, and in an animal research facility, a bulk of the overhead is in cage washing. A dollar not spent on utility costs is one that can go back into the research.”

By Liz Batchelder

This report is based on a presentation Zynda and Hinchcliffe gave at the Tradeline 2012 Animal Research Facilities conference.

| Organization |

|---|

|

Payette

|