When the Institute for Animal Health in Pirbright, U.K., launched a significant upgrade of aging infrastructure to improve health- and safety-related systems at its high-level containment facilities, project leaders undertook a benchmarking process to determine how much the upgrades would cost to operate and how Pirbright's organizational structure compared with similar facilities in preparing to meet long-range goals. The study—which included information received from eight sites as identified by Pirbright management and by Merrick & Company—had its challenges, but the exercise provided some general insights into how costs can be managed at similar facilities, as well as basic guidelines for benchmarking.

“We were looking at technical service operation dollars as the primary motive,” says Paul Langevin, project engineer and director of laboratory design services at Merrick & Company. “However, we also saw this as an opportunity to find out a little bit more about operational challenges, everything from energy management to preventive maintenance requirements to leaks.”

One of their main findings was the importance of standard operating procedures (SOPs) and how they are critically important to the operation of a facility. By asking specific questions—How do facilities define the containment criteria of the areas below and above the containment area? And how do they operate those spaces? (e.g. Is the security screening the same for the people accessing the filters as the program people on the floor?)—management can influence the total cost of operations and also allow opportunities for adopting new procedures to effect change and savings.

“It’s all predicated on risk management linked to local SOPs with the use of Personal Protective Equipment (PPEs), so the procedural side of these facilities is key to proper operational support,” says Langevin. “In my opinion, we have continued some historical paradigms in the last 20 years of overbuilding facilities for containment. I think the risk, from a secondary barrier design point of view, is quite low with exception of large animal containment rooms which are in effect the primary barrier.”

Getting Started

The leaders at Pirbright presented three key questions they hoped to answer with the study, says Langevin:

1) When you add footprint to your facilities, what is the impact on the cost to operate and maintain those facilities, and how can you accurately project and capture those costs?

2) With the complexity of today’s buildings, what additional assistance (people) and controls, building controls, and operative and technical talents/competencies are needed?

3) Does the current organizational model, slightly expanded or modified, meet the long-range vision for proper operations, and how does it compare to similar facilities?

Langevin and Steve Copping, head of safety and compliance at the Institute for Animal Health, chose seven sites in addition to Pirbright to survey: Institute for Virology and Immunoprophylaxis, Mittelhausern, Switzerland; Ministry of Agriculture, Riems, Germany; Health Protection Agency, Porton Down, UK; Canadian Science Center for Human and Animal Health, Winnipeg, Canada; Agriculture Research Service/Animal and Plant Health Inspection Service, USDA, Ames, Iowa; Biosecurity Research Institute, Kansas State University, Manhattan, Kansas; and Australian Animal Health Laboratory, Geelong, Australia.

They kept the survey short, with 36 questions focused on containment operations and comparative differentiators, covering topics including operational approaches to security, preventive/predictive maintenance, costs, staffing, failures, and service contracting. The sites were sent the questionnaire six weeks in advance of site visits and teleconferencing to help them work through the responses, says Langevin.

Comparing Organizational Models

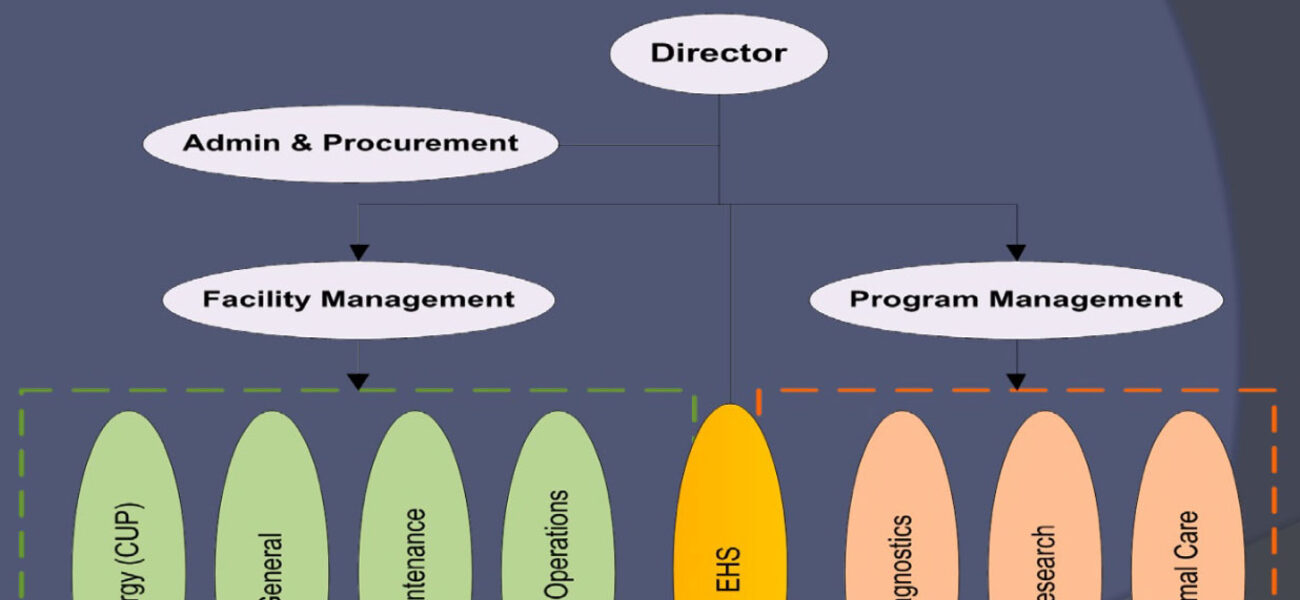

Each site’s organizational model was slightly different, but they found four essential elements:

1) Administration and procurement (leadership)

2) Health and Safety (regulatory responsibilities)

3) Facilities Management (technical services)

4) Program Services (science operations)

“We found that there wasn’t one constant model, and that people at every site believed their model was the best, of course,” says Langevin. “Many times there were local laws, local unions, and local paradigms that had been built over years that justified and supported their model.”

Within the management categories, there’s always a discussion as to who should take the lead; many facility directors have strong scientific backgrounds, and sometimes the safety and technical groups believe they require more profile and control to effectively manage their functional operations. Ultimately, each site needs the appropriate budget and authority to properly and safely operate their integrated functions, says Langevin.

In the health and safety group, roles and responsibilities and whom they reported to were inconsistent at some of the sites.

“The health and safety groups in some cases didn’t have as much authority as they probably should,” he says. “We felt that there probably should be a stronger relationship between the health and safety and the compliance side directly to the lead decision maker on a site.”

The facilities management group is key in supporting the technical function of the facility, notes Langevin. Often the administrators of an organization will control the technical facilities team, and sometimes the safety aspect as well.

“Sometimes safety services gets placed within the facility management group, and there is a muting effect if there are too many tiers between the technical support and safety enforcement and the directors of facilities.”

The survey revealed a variance in the approaches to preventive maintenance. Since utilities (supporting HVAC) and maintenance, custodial, and other property-related costs (parking, snow removal, security) represent up to 70 percent of the operational budget, this is an important area to look at for cost control, says Langevin.

“When we look to how we can save, how we can make sure the science is achieved cost effectively, we have to look at ways we can influence these changes,” he says. “It comes down to good designs. It comes down to HVAC and utility management, and making sure the size of the workforce is applicable to the job at hand, and that the people are active in their technical program responsibilities.”

Some organizations have internal policies of contracting out technical services support, but this tended to create duplicate efforts because they required additional people to manage and monitor the contractors.

“In high containment, it is a balance between what you believe is critical for controlling operations with in-house staff versus what is appropriate for contract services,” says Langevin.

Comparing Apples to Apples

Because there are numerous variables from country to country it makes direct side-by-side comparison inappropriate. Langevin says they standardized the data to a UK baseline by using five country adjustment factors: currency, salaries, thermal variations measured in degree days, unit energy costs, and preventive maintenance.

When the adjustments were factored in, the raw maintenance and engineering site costs at the eight facilities ranged from $5 per sf to $30 per sf, with the average being $16 per sf. For containment level specific operations, the baseline estimated costs they came up with were $29 per sf for a BSL-2 lab, close to $90 per sf for BSL-3 labs, and $228 per sf for a BSL-4 lab.

“Those are the average numbers I would suggest to anyone who is going to build. If you are building a high containment BSL-3 lab, it’s important that the correct capital and operational costs are made available to make sure you do a reasonable job,” explains Langevin.

Trends in High Containment

Langevin says the Pirbright study revealed several trends in high containment:

1) Building automation allows refined building performance data.

2) Redundancy of systems and application is not based on consistent risk assessments.

3) Regulations for physical parameters are performance-based and not from evidence-based engineering.

4) Engineering and maintenance costs are going up faster than inflation.

5) Regulation oversight is increasing.

“One trend coming forward in high containment is that building automation allows for improved knowledge and control of building performance,” notes Langevin. “We have debated that issue both from a cost aspect and also from the aspect of knowing what the building can do. With more technology, we know more about containment, but it also creates some of these challenges in knowing too much.

“I think at some point in time, we need to start doing better data analysis from all our samples across the world to be able to say what is the best redundant approach from a risk management and operational cost support.”

Challenges, Recommendations, and Conclusions

The study itself presented several challenges, including: the accuracy of data/records; survey response misinterpretations; High Containment Level area factor; country variations in solutions and operations that produce a wide range of results; and adjustment factor comprehensiveness and application. Langevin advises people to avoid direct country comparisons without some form of adjustment consideration.

Facility operators need to assess and challenge regulations based on risk/evidence-based research, he also concludes. One of the survey questions asked about changes in security oversight in the last 10 years, and the results averaged out to an increase of 4-7 percent. Because of global events, security costs have risen well beyond inflation at some sites.

“It is very important to look at what global shifts are happening and how that influences your operation, and project it out going forward,” he says.

Utility and HVAC are the most costly features in high containment operations, he notes—between 30-40 percent of the technical budget. Savings can be realized by recirculating air, reducing air change rates based on risk, and recovering energy from systems.

Langevin further recommends:

1) Review organizational model for staffing levels and supervisor ratios closer to 5:1.

2) Review critical services for contracting-out options.

3) Review asset management for attaining a minimum of 75 percent preventive (predictive) maintenance vs. reactive (failure) maintenance.

4) Establish a staffing principle that engages technical staff competency for critical systems.

5) Establish a recapitalization strategy that maximizes facility lifecycle.

Facility planners should be conscious of not overbuilding or over designing containment spaces without assessing organizational and operational costs strategies in advance for new projects.

While their exercise shows that benchmarking is useful, individual assessments should always be considered, Langevin adds.

By Taitia Shelow

This report is based on a presentation Langevin gave at Tradeline's 2012 International Conference on Biocontainment Facilities.

| Organization | Project Role |

|---|---|

|

Merrick & Company

|

Architect

|