“Smart labs” and the Internet of Things—with sensors and actuators that gather information about the lab environment and adjust its systems according to that data—have been around for a while. But a new wave of construction is allowing designers to incorporate smart concepts from the ground up, providing sensitive and responsive ventilation and airflow systems to a newly COVID-sensitized lab marketplace. Architects and engineers are working together to create flexible systems that respond in real time to conditions inside a research lab. “In a nutshell, we would like a smart building to operate in correlation with its occupancy and utilization,” says Tom Smith, president and CEO of 3Flow.

Smith may have tested more fume hoods than anyone in the world. He began as a college student, working in the health and safety office at the National Institute of Environmental Health Science. Among other things, he was a contributing author for the most recent update to the ANSI/ASSP Z9.5, the U.S. standard for lab ventilation. “As we progress through COVID, not only is safety important, but so is sustainability,” he says.

The COVID-19 pandemic has added a renewed emphasis on human safety to the airflow equation. “There’s a much greater focus on ventilation,” says Smith. “Institutions are much more aware of whether their ventilation is appropriate for their safety. There’s also an awareness of how transmission occurs, of ventilation effectiveness, and the use of filtration to help mitigate risk.”

Information Layer

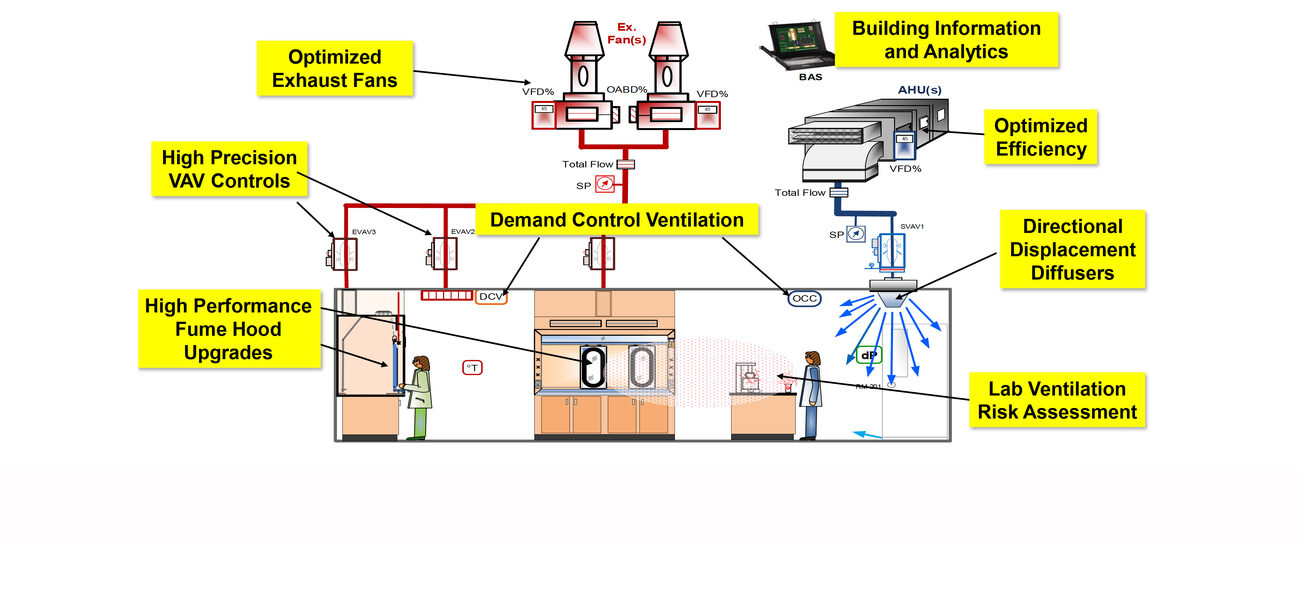

Paul Fuson, national business development manager for the life sciences division at Siemens, recalls 2007 and 2008, when the “smart lab” concept was introduced at the University of California, Irvine. This concept added an “information layer” to traditional research lab design—a layer that later grew to include the sensors and actuators of the Internet of Things, and the software and visualizations that allow machines to automate basic lab functions, and humans to see what’s happening in a facility in real time.

“The key is to improve the lab’s performance while making it safe for the occupants, but also making it a place to foster innovative opportunities,” says Fuson. “In our business, it’s still an issue if you get hot and cold complaints. That person is distracted from the science they’re trying to accomplish.”

Smith agrees. “The importance of ventilation is to create an environment that is safe, but it’s also conducive to the work.” He emphasizes that every lab design needs to prioritize human safety, keeping in mind that many researchers are required by the nature of their work to interact with hazardous materials.

At the same time, lab buildings use three to eight times more energy than traditional offices, so sustainability advocates and frugal administrators can join forces in welcoming any innovation that improves energy efficiency without cutting into safety or research success. Roughly two-thirds of energy use in labs is associated with ventilation, making that a significant target area for automation and efficiency-enhancing designs.

First, Eliminate Risks

Smith encourages lab designers and managers to begin by understanding the kinds of science for which their buildings will be used, and planning thoughtfully to reduce risks, for instance, making sure stack discharges do not re-entrain back into the building’s air supply. Industry groups have various standards and research documents available to help with this.

“Ultimately, we’d like to know the minimum flow and the range of modulation that’s necessary to meet the needs of the occupants to provide that safe, energy-efficient, and sustainable environment,” he says.

Institutions and companies sometimes get stuck thinking about ventilation in terms of air changes per hour, says Smith, but there is no standard number that can provide safety and efficiency in all settings. Instead, engineers and architects should drive the conversation toward planning for the specific types of risks expected in each space.

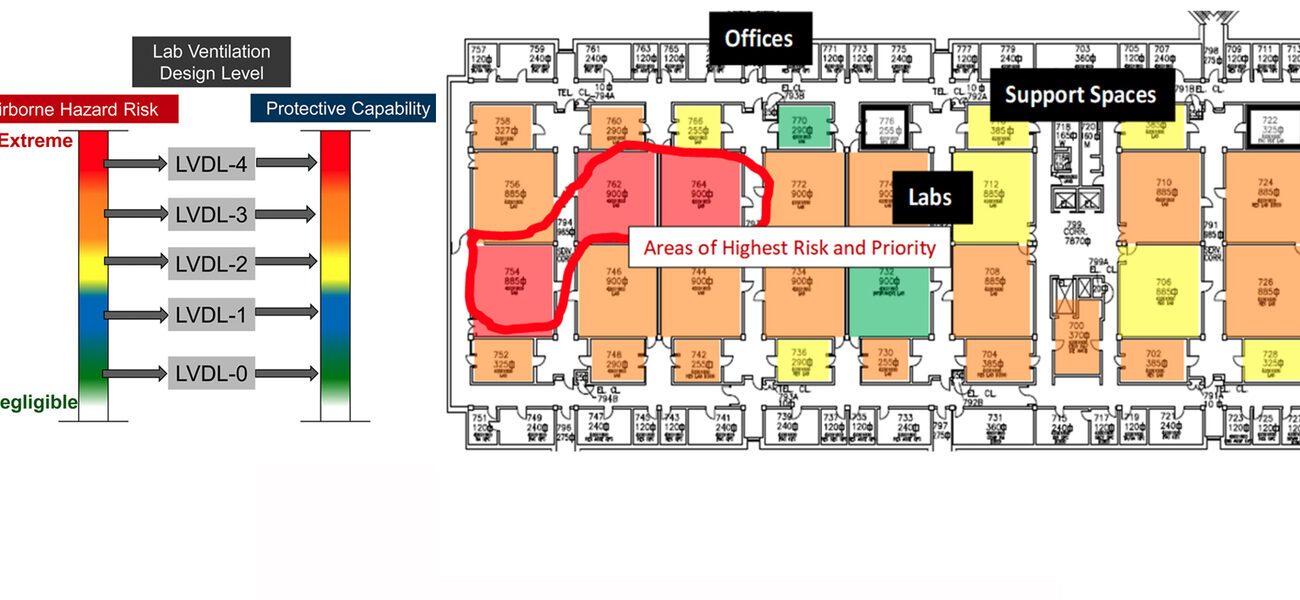

Smith worked with ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) to develop a five-point risk assessment scale that can be used when planning new or renovated lab space. “It recognizes that the spectrum of risk can range from people using very small quantities of low-hazard chemicals to working with chemical warfare agents or large quantities of highly toxic materials, or new materials where the risks aren’t even known,” he says.

“The reality is that you don’t always have the best conditions,” explains Fuson. The revised standard establishes the requirement that lab managers should write down their ventilation plans. It also sets expectations for what information the environmental health and safety people should provide to designers, and what training designers should provide to safety engineers. “It’s an educational tool as well as a standard,” he says.

Working With the Data

As part of the Smart Lab Solution, Smith helped develop a lab ventilation risk assessment that puts the standards into action. The assessment tool is now part of the U.S. Department of Energy’s Smart Labs program and available through the I2SL Smart Labs website.

Once a space has been assigned a risk level, it’s possible to estimate the cost of appropriate air handling technology, both as an initial investment and in terms of ongoing costs. “It becomes very, very expensive to operate these level 3 and 4 facilities, so we want to right-size the spaces,” says Smith. “An important parameter is to derive the operational specifications. We don’t need to guess or use rules of thumb. We can apply appropriate specifications to the devices based on the risk.”

Using a scorecard approach to assigning risk control bands, assessors in an RCB-0 (Risk Control Band-0) lab might find a need for temperature control, but no inhalation hazards. A level 4 lab, on the other hand, might require dilution ventilation, sophisticated fume hoods, and higher-level monitoring. Rating each lab and fume hood becomes an important part of documenting the decisions that went into the facility design, whether it’s a new lab or a renovation.

“Each hood and lab gets a rating that gives an RCB assignment. Based on this, we can look at the distribution of risk in that space,” says Smith. “Why would we design all spaces to level 3 if they’re going to be used for level 1? Now maybe we can design them with the physical attributes and capacity to accommodate a level 3, but operate them as a level 1 until they’re needed. It gives us a way to scale the operation of the facilities. Now we have a site map of where the risk is.”

With that map in hand, a design team can plan for flexibility, so that a certain percentage of the level 1 space can be raised to level 3 if needed. “We have limited resources, so that’s where we need to focus our efforts,” says Smith.

What We’ve Learned

Fuson says better information—including written airflow plans, as well as information gathered by sensors and processed by smart building systems—has led to safer labs. For example, “controllers can tell you if someone was leaving fume hood sashes open,” he says. “Thirty years later, these labs really are cleaner. They really are being run more safely.”

There’s also a renewed emphasis on retaining high-value laboratory staff—staff who can feel uncomfortable with unwieldy or out-of-date facilities. “You need to have a building that’s as smart as the people using it,” says Fuson. “Buildings are tools to get work done and to retain people.”

Today, a smart building is expected to do more than just report conditions—it can be programmed to respond in real time. Designing a building to cope with extreme worst cases is expensive, Fuson points out, and it’s much more practical to build in as much flexibility as possible. “The building’s going to be smart because it’s being designed to deal with different situations and is economical, capable of being operated at higher levels when needed,” he says.

Smith sees a rising number of institutions employing people with titles like “airflow manager” and “sustainability manager,” giving them a point person to deal with facility-related knowledge and training.

He says the next step is for building managers and laboratory teams to get the training and knowledge they need to deploy smart lab solutions and make the most of their facilities. “Once we understand what the requirements and usage are, people can be trained to apply these technologies to design and maintain buildings,” he says. “Right now, the technology is outpacing the knowledge and resources available.”

By Patricia Washburn