New teaching facilities for science and engineering stress flexibility and interdisciplinarity, but how much flexibility is appropriate? Michael Lauber, principal at Ellenzweig in Boston, cites three recent university-level projects at Michigan State University, University of Maine, and Rice University to demonstrate how to achieve varying levels of flexibility with lab infrastructure and casework, and how the floorplan can enable occupants to easily adapt their space to ever-changing pedagogical goals in multiple STEM disciplines.

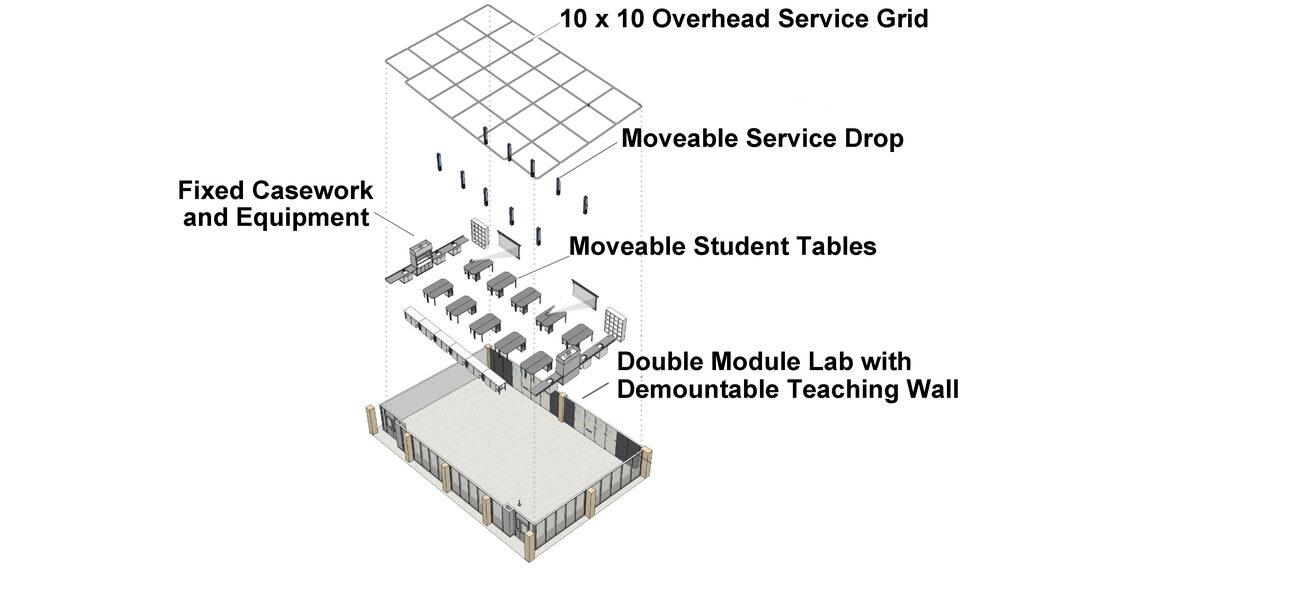

“Common elements are overhead grid systems that run power and utilities throughout the space, and movable casework and benches that can be reconfigured based on specific projects or teaching styles,” says Lauber. “These trends first began in research laboratory design and have spilled over to academic facilities, where we are now seeing an increased interest in flexibility.” He added that another common trend is fixing elements such as sinks and fume hoods around the perimeter, so that the middle of the space can easily be reconfigured.

Benches themselves can be designed for flexibility with height adjustability and removable shelves. He also recommends evaluating floorplate flexibility, as opposed to just within-the-room flexibility, since options can range from larger ballroom style spaces to longer, skinnier footprints. Both configurations offer options for long-term flexibility.

Even though some institutions prefer to keep labs designated for use by just one discipline, such as biology or chemistry, he says it is possible to specify equipment and design the layout to accommodate any kind of wet science or engineering in the future.

Michigan State University

The new $90 million STEM Teaching and Learning Facility at Michigan State University in East Lansing comes closest to exemplifying ultimate flexibility, says Lauber. He points primarily to the use of a unique Waldner overhead grid system and the fact that all lab spaces at MSU can easily convert between disciplines by using a modular design approach.

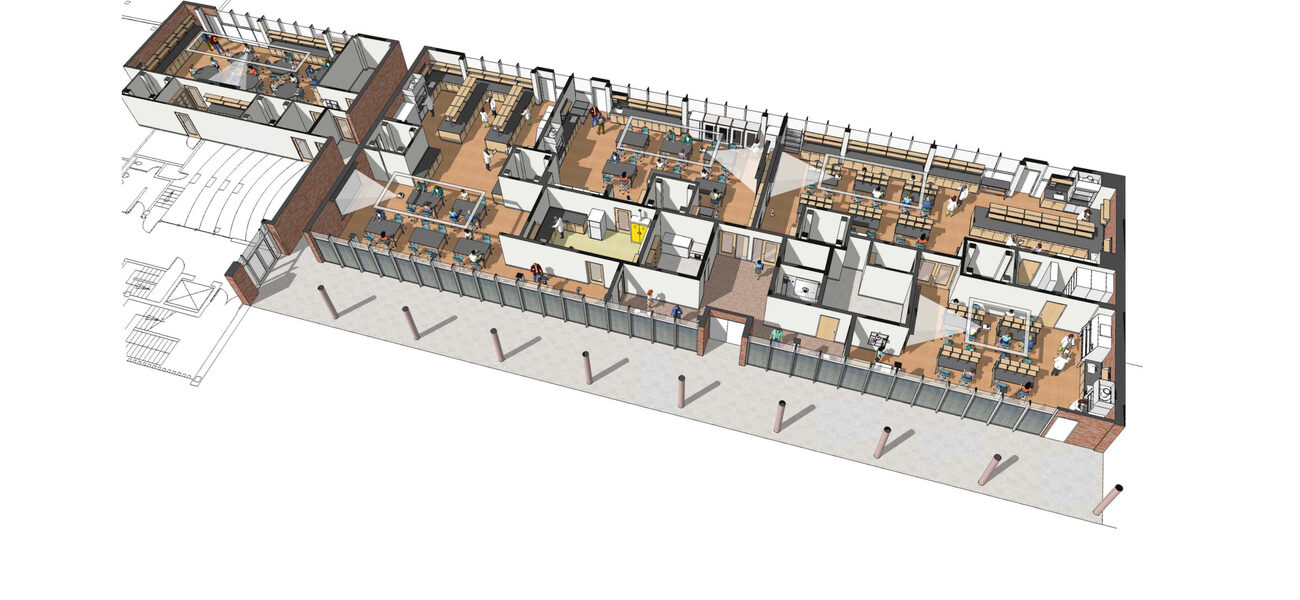

Ellenzweig partnered with Integrated Design Solutions, of Troy, Mich., to design the new facility, which includes a 134,000-sf addition to an existing 40,000-sf 1940s abandoned power plant. Prior to this facility opening in July of 2021, MSU had separate buildings for chemistry, biochemistry, and biology. This new facility brings all introductory labs into the same building to create an interdisciplinary center for STEM-related education. The former power plant now serves as the central collaborative hub, flanked on one side by a wing of dry labs and classrooms and another dedicated to wet labs and classrooms. The perimeter hallways provide areas for student breakout spaces.

“At MSU’s new facility, flexibility can also be defined in terms of modularity,” says Lauber. “We wanted to make sure that no matter what discipline the lab is, it will fit within the parameters of what we defined as a small, medium, or large lab footprint.” He adds that because the building had a large ballroom floor plan to work with, modular labs within the ballroom can easily be interchanged over time. One small module is defined as 42 by 30 feet. Two single modules can be put together to form a medium at feet 60 wide. The same logic applies if a triple module is needed, measuring 42 by 90 feet.

Each module contains movable lab benches and eight-person tables that can easily be removed or added when needed, which proved useful when the building first opened, and Covid-19 forced faculty to separate tables to achieve greater distance between students. As restrictions eased, the layout could easily be changed back to accommodate more students.

The Waldner overhead grid system, composed of extruded aluminum, uses a special fastening technique so that all lab services can be flex-connected to service columns that provide power, air, vacuum, or gas directly to the benches. To accommodate the modular sizes, the overhead systems are designed as 10-by-10-foot service grids, and all casework and benches can easily be moved to align with the overhead grids.

“Since the only fixed elements in the labs are sinks and fume hoods, the options of how MSU can arrange and rearrange their labs are endless,” says Lauber. “The physics labs don’t need the same type of services as wet labs, so they are using the Waldner system as an organization tool by suspending some experiments from the overhead grid.”

University of Maine

The new $78 million, 108,000-sf Ferland Engineering Education and Design Center at the University of Maine, Orono, (UMaine) is the most progressive building on their campus to date, according to Dana Humphrey, dean emeritus of UMaine’s College of Engineering. So much so that the building now serves as the starting point of every tour for prospective students who come to campus, regardless of whether that student intends to study a STEM-related discipline.

The building, which opened in August 2022, was designed by Ellenzweig in partnership with WBRC Architects of Portland, Maine.

Humphrey describes the Student Project Design Suite on the first floor as the heart of the building. The suite includes two flexible project labs, each with 22 movable workbenches with an overhead grid system to move utilities to benches wherever they are located. Ferland also has five collaborative classrooms with furniture that can be arranged in groups of four to eight, with the ability to move large screens to the end of each grouping so that students or faculty can wirelessly connect their laptops to the screens.

“Ellenzweig helped us achieve flexibility in both lab and classroom design and in our furniture selection so that we can be prepared for future growth,” says Humphrey. “The design team suggested the use of movable benches with removable shelving and an overhead grid system that allows access to utilities without compromising bench space.”

Rice University

Ellenzweig’s work at Rice University in Houston focused solely on renovating five biology teaching labs located in the 9,000-sf renovation of the MD Anderson Biology Center, which was completed in 2017. Rice faculty wanted flexibility in each lab to be able to reconfigure students’ tables and benches depending on the project. Some labs used only fixed perimeter benches, while others had fixed benches placed for specific instrumentation. All labs have movable student benches in the middle of space and use an overhead grid system to deliver power to the benches. One of the Rice labs also uses the overhead grid system to deliver natural gas with quick disconnects.

“Delivering natural gas through an overhead grid system is pushing the envelope, and this was the first time we have done this in an academic teaching facility,” says Lauber. “There are numerous safety concerns whenever natural gas is involved, so our design team had to be very careful about developing a flexible system that would meet rigorous safety standards yet still provide the flexibility the faculty wanted to be able to move benches and casework in the future.”

By Amy Cammell