Changing needs for vivariums have presented facilities managers with an array of challenges: creating more space for housing research animals within existing facilities; ensuring that the environments in which animals are kept meet guidelines set by scientific research agencies and organizations; and ensuring the spaces in which researchers conduct their experiments host well-run vivariums that contribute to, rather than inhibit, the ability to reproduce their results. Manufacturers are responding to these needs with more space-efficient caging systems, more precise and cost-effective environmental controls for animal holding rooms, and technology that can automatically track the health of animals in cages.

The need for reproduceable findings in animal research became a center-stage concern with the publication of a 2012 study by Amgen researchers in which the scientists said they had tried and failed to reproduce 90 percent of 53 landmark papers on cancer research. Subsequent studies have shown the average is closer to 60 percent, says John J. Hasenau, principal at Lab Animal Consultants, based in Sparks, Nev., but the issue remains that researchers need to find cost-effective means to improve their laboratory environments. “Without that reproducibility, we lack a lot of confidence in the science that we are doing,” he says.

“That is an alarming concern, not only for us as research individuals and professionals supporting the research industry, but also the lay public,” says Hasenau. “If we are not getting good reproducibility, then most likely we are not getting good translatability.”

The concern carries over to the billions of dollars invested in supporting that work, says Hasenau. In response, the industry has been working on several fronts to bring more consistency to vivariums: systems that automatically manage conditions in the animals’ living environment, more efficient caging systems, up-to-date guidelines for the management of laboratory animals, and automated monitoring of the animals in their home cage.

Reporting Guidelines

The U.S. National Research Council’s “Guide for the Care and Use of Laboratory Animals,” updated in 2011, establishes a set of vivarium conditions managers must monitor to receive accreditation, including temperature, humidity, light, air flow, and atmospheric pressure. In recent years, other scientific organizations have published recommendations for researchers to improve the precision and reproducibility of results:

- “Guidance for the Description of Animal Research in Scientific Publications,” also published by the National Research Council in 2011, provides guidelines for information about research animal studies that should be included in scientific publications.

- Animal Research: Reporting In Vivo Experiments (ARRIVE) Guidelines,” first published by the U.K. National Centre for the Replacement, Refinement and Reductions of Animals in Research in 2010, then updated in 2019, is intended to maximize information published about animal research studies while minimizing unnecessary studies.

- “Principles and Guidelines for Reporting Preclinical Research,” published in 2014 by the National Institutes of Health, promotes best practices in rigorous statistical analysis, transparency in reporting, and data sharing.

- “Enhancing Research Reproducibility,” a set of 2016 recommendations from the Federation of American Societies for Experimental Biology, promotes clear definitions and parameters for use by scientists, policy makers, and journalists to describe research.

- Protocols.io, an online sharing repository of different research protocols, enables scientists to view each other’s results and methods.

- “PREPARE guidelines for planning animal research and testing,” published by the U.K.-based Universities Federation for Animal Welfare in 2017, is a resource for scientists to help them plan experiments.

Hasenau says that he expects the Institute for Laboratory Animal Research (ILAR) and the American Association for Laboratory Animal Science (AALAS) to publish another set of guidelines that will combine many of the best practices mentioned above into one document.

Building Management Systems

Three technology trends are making it possible to automate a range of building systems, from HVAC and security to washing and ventilating animal cages, and monitoring the health of the animals. Cloud computing provides affordable and flexible computing power as needed; systems using machine learning and artificial intelligence enable computers to automate certain tasks; and the Internet of Things (IoT) embeds sensors that wirelessly connect remote machines to computer systems. Together, these technologies enable building automation systems (BAS) to become smarter, says Hasenau.

The technologies offer facilities managers different ways of monitoring systems in facilities that house laboratory animals: vivarium-specific systems, in which animal care groups manage the system and its related data about conditions in animal holding rooms; an institution’s security or facilities group takes charge of building-wide systems; or systems can be installed that use sensors to monitor vivarium conditions and provide alerts via online interfaces. All can lead to more efficient use of resources and stronger controls on vivarium conditions, says Hasenau:

- Siemens’ APOGEE employs the TALON building control system to monitor and adjust conditions such as air flow, temperature, humidity, and lighting.

- Avidity Science, formerly known as Edstrom, has a system that monitors automated watering, temperature, humidity, and air pressure inside the vivarium.

- Aircuity offers systems that monitor air quality through vivarium ventilations systems and adjust air changes accordingly.

Vivarium Upgrades Through Efficient Space Utilization

With the rising demand for animal research housing in addition to aging buildings and equipment, facilities owners and managers face an important challenge: upgrading their facilities to fit more research space at a manageable cost.

As these facilities matured, and as other research moved into the vivarium, the animal holding space became much more of a premium, says Brian Geyer, vice president of sales at Tecniplast USA Inc, based in West Chester, Pa.

A less costly alternative to constructing a new building or expanding existing structures is fitting more animals into the same spaces in a way that enhances animal welfare, promotes energy conservation, and saves money.

Recent advances in the design of individually ventilated rodent cages (IVCs) allow for more efficient use of existing space. Higher-density cage racks can fit 192 cages per rack instead of 140 or 160 in a comparable space, for example.

Trends in research facilities support this move, says Geyer. In the 1990s, architects designed research facilities around large animal holding rooms, each catering to multiple researchers. It was common to have from 800 to 1,500 cages in each room.

Until 2005, a typical animal holding room would be designed to hold about two-plus cages per square foot in a 16.5-by-24-foot space, or 395 sf, totaling six 140-cage racks, or 840 cages. The double-sided racks formed a peninsula off the wall, which provided the highest cage density at a lower cost compared to single-sided racks. This proved to be operationally challenging for the staff, however, when staging equipment for weekly or biweekly change-outs.

Around 2005, the design of animal holding rooms shifted. Newer layouts within the same dimensions placed the double-sided racks in a central island, with single-sided racks along the walls. Although the double-sided racks were a little more expensive, this approach opened up the space and allowed facilities to operate more efficiently. It was during this period that facilities began to incorporate higher density racks (single-sided holding 70 to 80 cages, and double-sided with 140 to 160), which enabled the same 395-sf room to hold 960 cages, or 2.4 cages per square foot, an increase of 14 percent.

More recent trends and demands have required manufactures to design racks with even higher cage density (HD) to house more mice in less space, because institutions are repurposing existing rodent housing space into specialty research, such as behavioral, gnotobiotic, and zebrafish housing. Manufacturers responded by reducing the height of the standard cage base from the 5-inch industry standard to 4 to 4½ inches. This allows the HD rack to maintain the same footprint while holding 12 rows instead of 10. The new double-sided rack, which is about 1 inch taller, holds 192 cages, and single-sided racks hold 96.

In addition to accommodating more animals, HD racks increase the per-diem revenue that facilities typically generate through research support. Conservatively speaking, says Geyer, an increase from 140 to 192 cages could mean an additional $1,092 per month per rack, based on a 70-cent charge per cage, or $13,104 per year before fixed costs are calculated. Accounting for fixed costs, he says it could still add $9,000-$10,000 in annual revenue per rack.

The HD racks have the same air volume as lower-density models, says Geyer, so they should have little impact on building operations. The total rack volume remains similar, since there is a reduction in cage volume with the reduced cage height on the HD rack. However, the technology is so new that there is still information to gather regarding its impact. For example, engineers are evaluating how much more heat the higher-density models produce and how that might affect other environmental controls. Lighting should not be affected, because the height of the HD racks is very similar to older models, but manufacturers need to gather feedback from facility managers as they gain experience with the equipment.

Controlling Ventilation

When it comes to ventilation, several types of systems are available for IVCs:

- stand-alone blowers that allow multiple racks to be connected to one blower

- fans mounted on the walls or ceiling of the animal holding room, with connections to the building HVAC system

- blowers mounted on the IVC racks

- multiple fans to supply conditioned air to the ventilated rack and direct the exhaust air into the building’s HVAC exhaust system

- full HVAC integration for both supply and exhaust conditioned air

Ventilation is a key element of humidity control, which is a challenging condition to regulate in compliance with laboratory animal guidelines. For example, the National Research Council’s guide states that humidity levels should be maintained between 30 and 70 percent, which can be a difficult standard during seasonal changes.

Relying on air handling units to control ventilation and humidity at the rack level is a worthwhile option to consider, says Geyer. Several manufacturers have developed systems to maintain humidity in the ventilated cage at 50 to 55 percent.

Such standardization supports the efforts of researchers to produce more reliable scientific outcomes and stay in compliance by precisely controlling air volumes at the cage level. It provides operational flexibility, too, because it’s easier to manage locally than it is to alter a building’s HVAC system. Be sure to check with the manufacturer for specific utility requirements for this application, cautions Geyer.

The multi-rack fan box design conditions the room air before introducing it into the cages on the ventilated rack and integrates into the building HVAC exhaust system, which is another option worth evaluating, says Geyer. This design, which is especially appealing for large rodent facilities, eliminates fans from the animal holding room; decreases the levels of equipment noise, heat, and maintenance activity the animals are exposed to; and reduces energy consumption.

Tecniplast looked at the potential cost savings for a Cambridge, Mass., project with 14 animal holding rooms, each 431 sf with 10-foot ceiling holding 880 cages (total cages: 12,320). The integrated ventilation system was able to control temperature and humidity while using 30 percent less energy than a multi-rack supply system.

Home Cage Monitoring Systems

For about 50 years, the mouse cage has been a box in which the animal lives. More recently, caging systems use technology to provide researchers and laboratory managers with information on environmental conditions, animal activity—or lack of activity—and other conditions, such as food and water availability in IVCs. This generally improves the reproducibility of research, and with a focus on activity, specifically enhances phenotype testing and resultant studies, oncology studies, neurodegenerative and stroke studies, as well as myriad other areas of research focus. Some caging systems are designed to minimize disruptions to the animals while collecting data on their movements and environmental conditions in each cage. These are what has been classified as “automated home cage systems,” allowing standard home cages—where animals are born, reared, and housed within their established social groups—to be monitored by various technological means: video and/or RFID, electromagnetic field disruptions, vibration, and infrared beam breaks.

Facilities managers and stakeholders need to discuss managing the collection, storage, and security of data collected by these technologies, says Hasenau. “These are the extremely large datasets that are being generated, so this adds a nuance to design features and architecture for the facilities,” he says.

A key challenge for scientists regarding their animal research models is monitoring the health of the animals in their cages. All the investments in a vivarium, the caging arrangements, and systems for ventilation and humidity control are essential, but if researchers don’t find out quickly if a mouse is sick—or worse, dead—it can affect their data. This is one application where automated home cage monitoring systems come in, says Laura Schaevitz, chief scientific officer at Vium Inc., based in San Mateo, Calif.

Checking on the status of mice in a vivarium typically involves handling the cages, because staff in holding rooms can’t see the animals, she says. “What do we do if we can’t tell? We take the cage out and manipulate it in some way. It’s incredibly stressful for the animal.”

This creates two problems: Disturbing the laboratory animals can affect the results of an experiment, because it can influence the animal’s behavior and wellbeing; and it is labor-intensive to put a staff member’s hands and eyes on hundreds of cages.

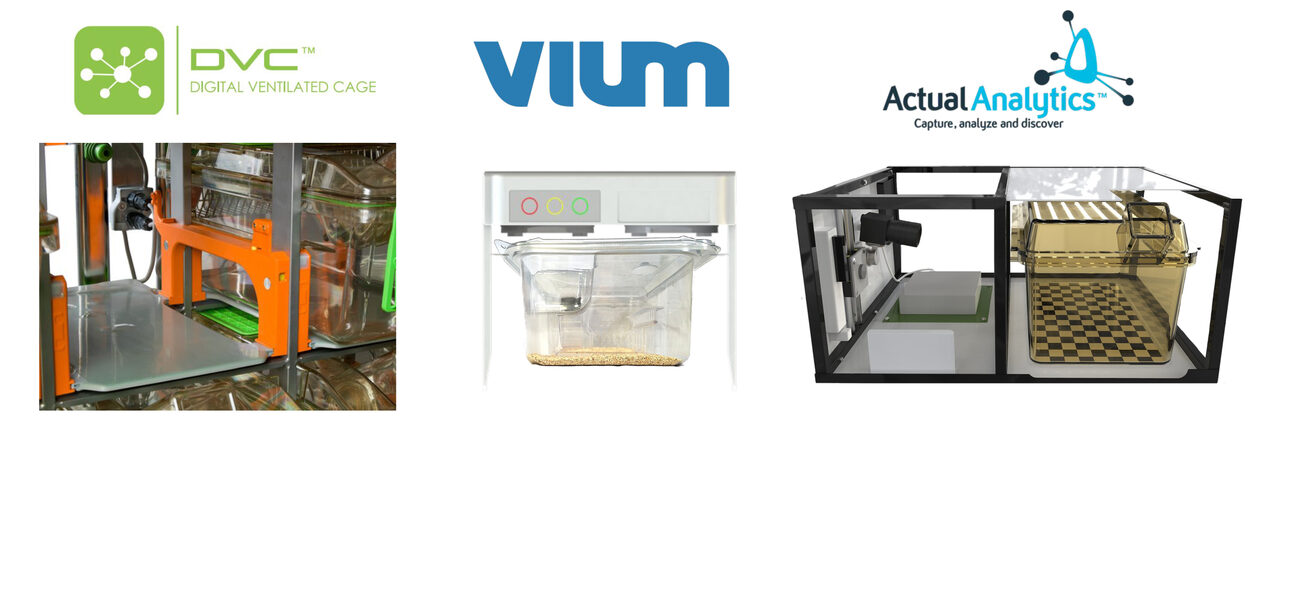

At least three companies have developed automated home cage monitoring systems to remotely and automatically check the status of individual laboratory animals, 24 hours a day: Tecniplast’s DVC™ (digital ventilated cage) system, Vium’s Smart Housing™ system, and Actual Analytics™. These systems combine video cameras or other sensors to collect data about conditions in each cage, software tools to analyze the data, and a cloud-based system to host the data and perform analysis.

Vium is using its systems to monitor the behavior and physiology of mice over the course of their lifespan, which can be more than three and a half years. The Vium Smart Housing system uses commercially available cages from Innovive, which are clear and disposable, mounted on a rack. Each cage position within the rack has:

- visible light LEDs (on the blue spectrum) during the day and infrared lighting at night, which allows visualization of the animals 24 hours a day

- a 1080p camera for high-definition video to view a mouse’s movements, including indicators like breathing rate, and percentage of time spent running on the wheel

- temperature and humidity sensors

- environmental enrichment, such as running wheel and ladders, and bedding materials

The cage rack is hardwired for Ethernet, and digital videos are stored on an Amazon Web Services cloud. The system currently tracks one mouse per cage, but the company is testing ways to track multiple mice in a single cage.

The system improves facility operations by reducing the burden of daily health checks. By tracking indicators about the animals 24 hours a day, the cage monitoring system provides alerts on abnormal behaviors, such as if a mouse shows signs of distress or poor health.

Lab managers can use cage monitoring data to refine their procedures, says Schaevitz. For example, data about a mouse’s condition before and after a blood draw or injection could indicate how one technician’s technique compares to another’s, which could lead to improved training.

Elevating the quality of work in the vivarium also has important implications for science, says Schaevitz. By collecting and analyzing data on many mice, for example, scientists can begin to understand the characteristics of a typical mouse, and work to make studies more reproducible.

“We’re talking with a number of our partners about creating a normal animal database, by getting better phenotyping on animal models, both behavioral and physiological,” she says. Reproducing studies “is not just about monitoring the environment that the animals live in. It’s also about monitoring the animals’ responses.”

In Vium’s own research lab, the company has collected 1 billion hours of data over four years, chronicling the conditions and behaviors of 65 strains of mice. The company has examined 30 disease models, ranging from respiratory and central nervous system ailments to cancer and cardiovascular disease, and has made approximately 600,000 annotations on procedures administered to mice, including blood draws and cage maintenance.

“You can imagine with all of this data, we now have the ability to learn a lot about our processes and how we can improve them, and the important scientific implications,” says Schaevitz.

One discovery Schaevitz’s team has made can help predict when a mouse is about to die: The circadian rhythms of mice—when they are still, when they run on a wheel, and how much of each activity they do—can change dramatically in the last few days of life. By tracking the data, scientists can offer more humane treatment when they suspect an animal is nearing the end of its life.

By Michael S. Goldberg

| Organization | Project Role |

|---|---|

|

Lab Animal Consultants

|

Vivarium Design

|

|

Animal Caging

|

|

|

Vium Inc.

|

Animal Caging

|