Texas A&M University is addressing the rising demand for engineers by transforming a traditional 46-year-old academic building into a state-of-the-art facility, where technology is not just an aid, but a driver. The Zachry Engineering Education Complex, on the College Station campus, is the cornerstone of Texas A&M’s ambitious “25 by 25” initiative—a plan to enroll 25,000 engineering students by 2025.

Before 25 by 25 was initiated, Texas A&M accepted only 1,600 of 10,000 engineering applicants annually. Such a dramatic enrollment increase to 25,000 students in less than a decade requires more spacious and varied facilities. The $228 million, 525,000-gsf Zachry complex, with its five floors, has about twice the capacity of the old building.

Used for classes and labs by all 14 engineering departments, the new Zachry includes a 56,000-gsf design center, nine common labs on three floors, 18 96-seat learning studios, 14 48-seat learning studios, learning stairs, and many rooms for students to meet and collaborate.

The fourth floor hosts some classes, but primarily serves as home for 10 programs associated with the College of Engineering, including Women in Engineering, Zachry Leadership Program, and Engineering Graduate Programs.

The College of Engineering’s upper administration can be found on the fifth floor, where the IT, facilities, and communications support groups also are located. A green roof terrace tops a third-floor roof structure with access from the fourth floor. Wi-Fi can be found anywhere in the building and on the E-Quad outside.

New Center Debuts in Fall of 2018

Work on the Zachry Engineering Education Complex was substantially completed in the spring of 2018, and the first students attended class in the fall. “The facility has worked pretty much as intended,” says Stuart Anderson, assistant vice chancellor of facilities planning and management for the university’s College of Engineering. “For the most part, expectations have been met.”

Built in 1972, the original H.B. Zachry Engineering Center, which housed various engineering departments, was constructed in a functional, generic style, lovingly referred to as “early penitentiary.” To prepare for the major renovation, the cladding was removed, and the inside was gutted, leaving the steel frame, floors, and ceilings as a starting point. A four-story distillation column in the high-bay lab area is the only item that remains from the original building.

The original Zachry housed a small nuclear reactor, which was used as a teaching tool in nuclear engineering. The reactor, which did not generate much power, was moved off campus to the Nuclear Science Center site supervised by the nuclear engineering department. “This reactor would light a lightbulb,” says Anderson.

Focus on Active Learning

The new home for undergraduate engineering, renamed the Zachry Engineering Education Complex, espouses active learning, which is generally defined as any instructional method that engages students in the learning process. That means more hands-on projects, smaller classes, fewer lectures, and greater contact with professionals from industry and the alumni network. Active learning requires students “to do meaningful activities and think about what they’re doing,” says Anderson. “It needs to be a team environment.”

The design area, with its emphasis on innovation, creativity, and fabrication, vividly illustrates the concept of active learning.

“In the design area, we have our project room, fabrication, and prototyping space,” says Stephen Franklin, executive director for facilities planning and management at Texas A&M. It’s where students put theory into practice. “You can have a teaching moment and instruction near a piece of machinery, so the instructor can take time out, give concepts, show how the machine is going to work, and then allow the students to work,” he says.

The project rooms are divided into short-term and long-term. Short-term projects last a semester; long-term works are understandably more involved, and include collaboration on major projects, such as self-driving and solar-powered vehicles. There also is a machine shop, with space for wood and metal; a painting booth; welding; and a mass prototype shop.

The new Zachry means machine shop work will not be scattered across campus.

“The great piece about this portion of the building,” says Franklin, “is that this allowed us to consolidate several areas we had across campus to bring them into one building. We had most of the machine shops across many different departments. Now we have one machine shop that is supporting the whole college.”

In addition to the shared machine shop, the Zachry building contains the following common labs: controls, cyber/physical, electrical measurements, electrical, fluids, high bay, instrumentation, and transport phenomena.

The layout of the labs promotes flexibility, says Franklin. “We can change at any time. It wouldn’t take long to take a control lab, pull it out, and expand the cyber/physical lab if we need to. It is mainly just a matter of moving benches because of the way we have our power, data, and gas.”

Such flexibility fosters collaboration, he says. Students function as a team in the labs and are free to work at any hour of the day—the labs are open 24/7 to engineering undergrads. Computer software from iLab has proven to be invaluable for scheduling student lab experiments, says Anderson.

T1V Engages Students

Another product, software designed by T1V of Charlotte, N.C., is making quite an impact in the learning studios. Some faculty members still prefer to lecture with a PowerPoint presentation or whiteboard; but with training, they can take advantage of T1V software to engage students.

“I would refer to it as bleeding-edge technology,” says Franklin. An instructor can turn an iPad into an 85-inch television screen, displaying the work of individual students for the entire class to see. “This is the wisest future-proofing, because TIV has enabled us to make changes through software programming, not hardware,” at a substantial cost savings, says Franklin.

“In a more active mode, students work together at tables, using laptops and popup screens to display lecture content, and then respond to problems using a popup screen, so that the entire class can see the answer,” he says.

Franklin credits the university’s IT group with landing on the T1V solution. “We were going to spend hundreds of thousands of dollars to be able to program hardware. T1V said, ‘Let us look at it.’ They came back in a month and solved it with a software fix,” he says. “So, we are happy about that. It is cheaper; it is faster; and it gives us a chance to move forward.”

Instructors and students can also take advantage of distance learning to various locations outside the building, to other Texas A&M campuses, or even different rooms within the building, using all of the same technology. “We heard a great story about two professors who were teaming together who had an occasion where one instructor couldn’t make it to class. Instead, the other instructor taught both classes in separate rooms at the same time,” says Franklin.

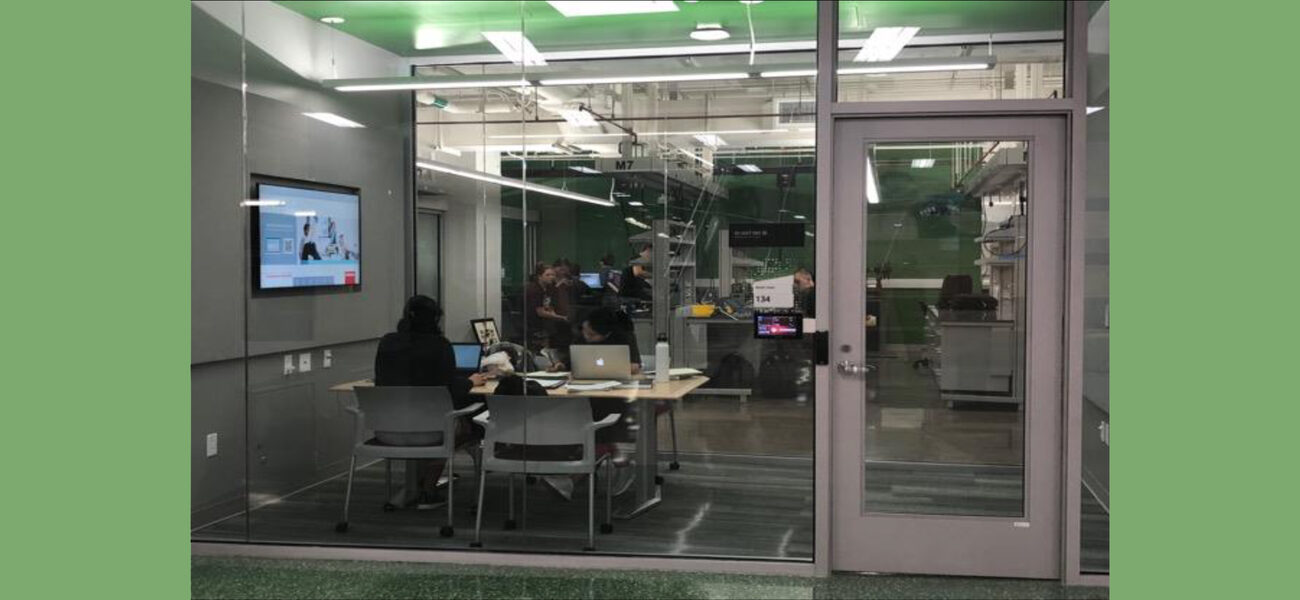

In addition to the design area, labs, and learning studios, the building provides ample space for informal learning. Study and huddle spaces, for instance, contain wall-mounted screens, screen connections for laptops, and whiteboards. They can accommodate as many as 14 students who want to study or simply hang out together. Open study areas offer power and Wi-Fi connections, while students can also connect to Wi-Fi on the learning stairs.

With its abundant natural lighting, atriums, huddle rooms, and high-tech options, Zachry has charmed the student body. One undergrad says, “Not only can you innovate and practice in your field, but you can socialize, and you can brainstorm, and you can relax with your friends.”

The administration has been pleased with the student response.

“When we opened the building in the first week, we had 4,300 students logging onto the Wi-Fi,” reports Franklin. “That number has stayed steady, and we are now running from 4,500 to 5,000 a day.” That includes non-engineering students, although their access to the Zachry is limited to 7:30 a.m. to 11 p.m.

The building includes a two-story resource center, run by the retention group, which aims to keep students in the engineering program—one of the prime objectives of the dean of the College of Engineering, Dr. Katherine Banks. An IT group serves students much like an Apple store, and one-on-one tutoring is available from anywhere in the world through distance learning.

“As engineers, we have been a little scattered all over campus,” says one Texas A&M student, “and we finally have our home base to come back to. I’m just so thrilled for it to finally be done.”

By Bob Stein