To support its cutting-edge research in self-operated machines, the Center for Autonomous Systems and Technologies (CAST) at California Institute of Technology (Caltech) is equipped with several groundbreaking capabilities that set it apart from other engineering research facilities. At the top of the list are a drone testing arena capable of mimicking a full gamut of real-world weather conditions, and a zero-gravity-simulating space lab whose epoxy resin floor has been ground and polished to a final flatness of 0.003 of an inch. Three CAST components—the aerodrome, assembly lab, and the Space Robotics Controls Laboratory (SRCL)—are located in the 1940s-era Kármán building, originally constructed for wartime hydrodynamics research. Working with CO Architects and Matt Construction, Pasadena-based Caltech renovated the bunker-like building to create new types of spaces for cross-campus collaborations in the expanding field of autonomous drones, robots, and satellites, with a focus on practical applications in science, industry, and medicine.

According to CAST Director Morteza Gharib, Caltech’s Hans W. Liepmann Professor of Aeronautics and Bioinspired Engineering, “The goal is to teach autonomous systems to think independently, preparing them for the rigors of life outside the lab.”

“Most experiments strive to reduce the number of variables, to find out how something reacts to one particular influence,” observes Andrew Labov, principal at CO Architects, a member of the contractor’s integrated design-build team. “Here, we want to introduce many, many variables all at the same time, just like what humans have to deal with in the real world. That’s what this facility is designed to do.”

Simulated Environments

Opened in October 2017, CAST encompasses four key facilities. The aerodrome, assembly lab, and SRCL occupy roughly 7,000 sf in Kármán, and the 2,500-sf advanced mobility lab (designed by another architectural firm) is in the basement of a separate building next door.

“The aerodrome and SRCL are designed to simulate a variety of environments in which flying, driving, walking, crawling, and swimming devices will engage and learn from these environments autonomously,” says Labov. “The most important lesson we learned in designing these spaces is that they are less about testing hardware and more about designing and developing the software that will enable a new generation of intelligent devices to learn from their surroundings, and self-correct without connection to any central navigation system.”

The Aerodrome

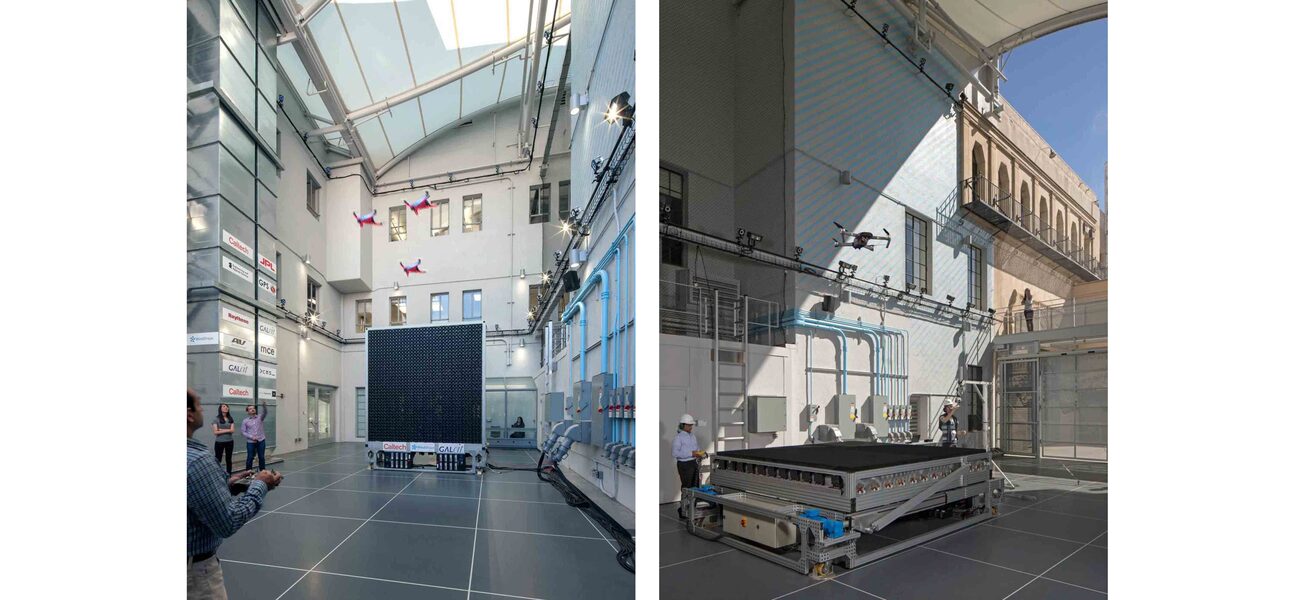

The 1,530-sf aerodrome, or testing arena, is one of the stars of the showplace that advances futuristic visions or “moonshot” challenges like autonomous flying ambulances, prosthetic legs that use machine learning to automatically adjust to a wearer's gait, or a swarm of flying sentinel drones that automatically activate during an earthquake to scan damaged areas.

The 30-by-50-foot, day-lit arena represents an inventive repurposing of a small back courtyard that once housed nitrogen storage tanks. Envisioned by the university as “a new type of space on campus,” it allows different types and sizes of autonomous machines to move around safely within a contained and mediated outdoor environment.

The highly flexible arena can be configured in numerous ways, ranging from landscapes to buildings and street scenes. Devices can engage with various types of natural and man-made obstacles under a gamut of atmospheric conditions, including rain, hail, sandstorms, and turbulence. A portable pool is available for testing submersible vehicles.

“During the concept and design stage, the initial inspiration for the arena was a movie soundstage, one which enables the quick setup and take-down of simulated environments,” says Labov.

A critical piece is the camera system installed to measure the accuracy of a device’s navigation performance. A total of 46 infrared motion-capture cameras are mounted on the wall at two levels, above the first and third floors, to capture and record drone activity. The cameras measure the drone’s flight path to within a millimeter, so that small distances can be extrapolated to simulate larger distances. A grid painted on the floor has marker points at each intersection to calibrate the cameras.

Tucked into the back corner of the aerodrome is a 140-sf observation room, a laminated safety-glass enclosure that allows the operator to sit within the arena and have complete unobstructed views of drones flying in all directions.

“Other facilities might have a drone testing space that resembles a large batting cage,” says Labov. “This one has room not just for the devices to fly but also an almost unprecedented ability to track and monitor their movement with a high degree of precision.”

Three stories tall, the arena is topped by a canopy of tensioned, translucent Teflon™-coated woven fiberglass fabric, providing even, diffuse illumination compatible with the infrared cameras. To meet seismic requirements, the canopy structure is fixed to the Kármán building and supported by slip joints attached to the adjacent building. The rigid stainless steel frame rests on Teflon pads that allow lateral movement.

Open-Air Wind Tunnel

Another CAST first is the aerodrome’s completely digital controllable fanwall, essentially an open-air wind tunnel.

“Wind tunnels are typically used to observe air behavior around an object to check its aerodynamics,” says Labov. “This turns the concept around—researchers are studying how drones react to changing conditions around them.”

Custom-designed by Gharib, the 10-by-10-foot modular fanwall consists of 1,296 independently controllable microfans that can generate wind speeds of up to 44 mph and be programmed to generate turbulent wind gusts. A side wall of 324 fans to create a crosswind will soon be added.

The fanwall can tilt up to blow horizontally, or tilt down to blow vertically, allowing drones to simulate vertical landings. When folded, the entire assembly can be rolled out of the arena through large double gates, freeing up the space for other activities.

How to supply and circulate air in the partially enclosed space, and mitigate the noise generated, posed significant design challenges.

“Air is drawn into the east end of the arena from a large mesh opening above full-height, perforated metal gates,” explains Labov. “The two-story opening with a coiled metal mesh screen allows a large volume of low-velocity supply air to enter the arena without affecting wind patterns. When the fanwall is operating, the large gates must be opened due to the high velocity of the exhaust air.”

The design team simulated airflow patterns using computational fluid dynamic modeling and acoustical modeling, based on performance information provided by Caltech’s fanwall engineering team, which then field tested a number of different fans in the space before making a final selection.

“This was a case in which the design of the space influenced the design of the apparatus, and vice-versa,” Labov continues. “It was a real collaborative effort, with a lot of back and forth between the teams.”

The fanwall’s heavy-duty power requirements are met by a dedicated transformer and switchgear set. Because the fanwall is movable, it is served from heavy-duty cords plugged into a set of 200A receptacles for the fan arrays and tilt motor, similar to those used to provide power to ships in port. AC power is provided to the fanwall. Each module of nine fans has an integral flat blade transformer that converts the power to DC, while not obstructing airflow.

Maker and Marker Spaces

The 1,230-sf assembly lab, or maker space, is a large, open room for troubleshooting both hardware and software, shared by researchers and students working on special projects and team competitions. Wall-mounted shelving alternates with large windows along the perimeter for a plentiful supply of natural light. Suspended from the ceiling is a rectangular grid of aluminum 80/20® tubing to support equipment and utilities, and a steel track and trolley system to which robots can be tethered for support as they learn to maneuver on their own. Oversized glass doors provide convenient access to the adjacent aerodrome.

The lab is equipped with several flexibility features. Movable tables, custom designed by CO Architects, are made from aluminum tubing supports and resin tops so they can collapse and nest for easy storage when a clear expanse of space is needed for the robots to move around. The sliding barn doors that conceal supply cupboards are covered with a writing surface that lets them do double duty as a place for researchers to make calculations and record notes.

At each end of the room are separate wet and dry fabrication areas for machine tools and 3-D printers, each glassed in to maintain control of dust and other atmospheric elements.

The adjacent marker space, designed for troubleshooting autonomous control software, can flex into additional workspace when needed. The glass-enclosed room has views through the assembly lab to the testing arena.

“This is more for the thinking side, away from the hardware,” says Jennifer Swedell, CO Architects’ senior lab planner. “Researchers can think out loud and start to diagram circuits that aren’t working. It’s a quiet place for troubleshooting software, where it’s not about fixing a broken device, but asking questions like why it got lost.”

Space Robotics Controls Laboratory

The 2,350-sf SRCL, in the Kármán basement and mezzanine, presents a completely different environment for autonomous device testing. In this case the drones are small spacecraft, or cube satellites (cubesats), which are being tested for their ability to fly in the vacuum of space. That happens in a two-story, 900-sf black-box theater that simulates the frictionless motion of space flight.

“Mock-ups of satellites use air bearings to float on a thin cushion of compressed air above a super-flat floor—somewhat like a reverse air hockey table—allowing them to simulate autonomous navigation in zero gravity,” explains Labov. “The air jets push the cubesats laterally across the room as they learn to navigate around obstacles, move in groups, and engage with a robotic arm that simulates docking maneuvers.”

“The satellites are operated from the main research laboratory, their movement tracked with infrared motion-capture cameras,” adds Swedell. “An all-glass bay window overlooks the testing space, giving researchers and visitors a direct view of the test in progress. Researchers at nearby workstations have a mediated view through motion-tracking software of the real-time experiment.”

Essential to the simulation, the super-flat floor was a major challenge to design and install. The expertise to achieve the mandated degree of flatness is in scarce supply, according to Swedell.

“Super-flat floors for aerospace testing were first used in the 1960s, when synthetic thermosetting resins and polymers became available for industrial applications,” she says. “These floors are very difficult to specify due to local micro-conditions during the pour and curing.”

In fact, the flatness criteria continued to increase during design, requiring ever tighter tolerances. A trial with a local contractor did not produce the required results.

“Ultimately, we found a contractor on the other side of the country who was endorsed by other aerospace researchers,” says Swedell. “He came to this specialty through his work with the auto racing industry, where chassis set-up work must be performed under high-precision conditions.”

The 5-inch thick floor, a proprietary epoxy resin mix blended by the vendor, was poured in multiple, self-leveling layers, and ground flat in between each successive pour. The process took one week from start to finish.

The air supply to the black-box is scrubbed with a 30 percent pre-filter and a 90 percent final filter, which is equivalent to hospital grade filtration, to minimize dust collecting on the super-flat floor.

Sensitive electronics fabrication, testing, and repairs are done in the SRCL’s 950-sf assembly lab, a positively pressurized, Class 100,000 clean room with HEPA fan filter units to scrub the air of dust and fine particles. The space lab also houses a 70-sf Class 10,000 cleanroom, three graduate student offices, and a meeting room.

Multiple Stakeholders

As a shared facility that serves faculty, students, and researchers from a variety of academic disciplines, as well as industry partners, CAST stands out on the Caltech campus, where researchers typically have their own labs and equipment.

CAST is operated by the Graduate Aerospace Laboratories of the California Institute of Technology (GALCIT). The main users will be more than two dozen engineers and scientists from three Caltech divisions—Engineering and Applied Science, Geological and Planetary Sciences, and the Jet Propulsion Laboratory, who recently used the fanwall to simulate the landing of an autonomous helicopter drone that will be sent to Mars.

Corporations and industry members will play a key part in the development of CAST technologies and systems. Raytheon, a lead sponsor and funding source, has assembled a team of senior engineers to work on the transition of CAST-developed capabilities in areas like autonomous navigation, artificial intelligence, and machine learning to new applications and market-ready products.

By Nicole Zaro Stahl