Engineered openings that minimize the turbulence of transfer airflow, along with a mix of control strategies between labs and anchor spaces, are a best practice for achieving stable pressurization in biocontainment facilities. “The golden rule of containment is to always maintain the relationship between exhaust and supply,” says Michael Clements, director of life sciences at WorkingBuildings, LLC. “To keep a room contained, airflow fluctuations in the exhaust require a reaction in the supply in order to maintain this critical relationship.”

While the rule is simple enough, maintaining these relationships can be complicated. Disruptions in the pressure relationship can occur for a variety of reasons: component failure, sensor drift, or even day-to-day operations. Moreover, the control scheme must address several seemingly competing criteria in the ongoing tug-of-war between stability and rapid response to events such as fan failures or power blips.

“Differential pressure control problems can be very frustrating and confusing,” notes Phillip Stanford, WorkingBuildings biocontainment expert, who, with Clements, led a study of engineered openings. “They present major biosafety issues and can prevent a critical facility from being able to perform its intended mission. It’s possible to have a simple, effective solution.”

Airflow: Quality and Quantity

There are common stability issues in biocontainment facilities that seem to transcend air valve selection, control system type, and program strategies. These common problems prompted Clements and Stanford to suspect that another factor, beyond the HVAC realm, could be driving pressure control issues.

“We felt like there was a missing piece of the puzzle that isn’t discussed a lot by designers, owners, engineers, or architects: turbulence. We talk a great deal about the quantity of offset (or transfer) airflow, but not so much about the quality—whether it’s laminar or turbulent,” says Clements.

Typical room pressurization is guided by a rule of thumb: It takes an offset airflow of 100 to 150 CFM per door to attain the target pressure. “This rule assumes the space is basically airtight with leakage only around the doorframe and the door undercut,” explains Stanford.

However, as is often the case with broad guidelines, there are exceptions, which WorkingBuildings discovered upon closer inspection. For one thing, the current rule doesn’t account for the unavoidable fluctuations in airflow caused by the mechanical components of the air system. A 5 percent margin of error on both sides of the airflow—supply and exhaust—could tilt the pressure relationship considerably, even causing a reversal of airflow, which has significant consequences.

Engineered Openings

To test their theory, Clements and Stanford studied four existing BSL-3 labs, each with multiple rooms of a consistent geometry (similar layout and door size, same controls). They collected 874 data points related to flow and differential pressure. The analysis of the data ultimately confirmed the relationship between differential pressure and airflow in the facilities as a function of the geometry of the transfer openings.

The most important factor to emerge from the data analysis was the quality of the transfer air—the air that is pulled from adjacent spaces rather than supplied by air handlers through the ductwork. Clements and Stanford determined through subsequent simulation that flow quality is “very relevant” to achieving stable containment.

The quality of transfer airflow, its N value, is measured on a range from 0.5 to 1, with 0.5 representing the most turbulent and 1 representing fully laminar. The best quality is the most laminar, the N value closest to 1.

“A room with turbulent leakage acts like an amplifier, making the existing fluctuations more pronounced,” says Stanford.

Clements and Stanford concluded that the best solution to minimize turbulence is a well-designed engineered opening. Further testing of a variety of opening configurations in an otherwise airtight demonstration lab revealed that a 4-inch pipe with an unimpeded opening delivered almost perfectly laminar transfer air with an N value of 0.98. Applying a slotted grate to the end of that pipe led to more turbulence, for an N value of 0.87. With the opening reduced to only a small slit, the N value went down to 0.71, confirming that the quality of the airflow can be manipulated to achieve an almost fully laminar condition.

“Since transfer air is needed, we should capitalize on it by manipulating the geometry of the opening to improve stability,” says Clements.

Offset Control Strategies: Progressive and Direct

The type of control strategy also has a big influence on maintaining the target pressure, especially in providing rapid response to events. The most common control strategy currently used is fixed offset control, which means the differential between the supply and exhaust flows is constant. In more critical facilities, there are two enhanced control strategies worth considering—progressive offset control and direct pressure control.

Progressive offset control focuses on the supply airflow. The exhaust rate is typically fixed, while the volume of transfer air varies in response to changing conditions.

“The control system looks at a room differential pressure sensor and sends the reading back to the supply valve,” says Stanford. “If the negative pressure starts creeping up or down, it will adjust the valve to try to compensate. So progressive offset control is inherently complicated. This is due to the system having to constantly reevaluate data from the sensors and make indirect adjustments to the supply airflow.”

A direct pressure scheme, on the other hand, abandons supply airflow volume control completely, instead directly controlling the pressure relationship. In this direct approach, the supply damper modulates to control the room pressure and maintains it at its setpoint.

“With direct pressure control, the exhaust controls the flow for ventilation and air changes. The supply valve doesn’t care about flow, per se; it only cares about keeping the pressure relationship and maintaining containment,” says Clements. “This direct-acting approach is simple and minimizes guesswork on the part of the controls contractor.”

To solidify the empirical findings, Clements and Stanford ran computer simulations testing four different schemes for pressure stability and responsiveness. The variables were the two control strategies (progressive offset and direct pressure) and transfer air quality—whether turbulent from an undercut door or mostly laminar from an engineered opening.

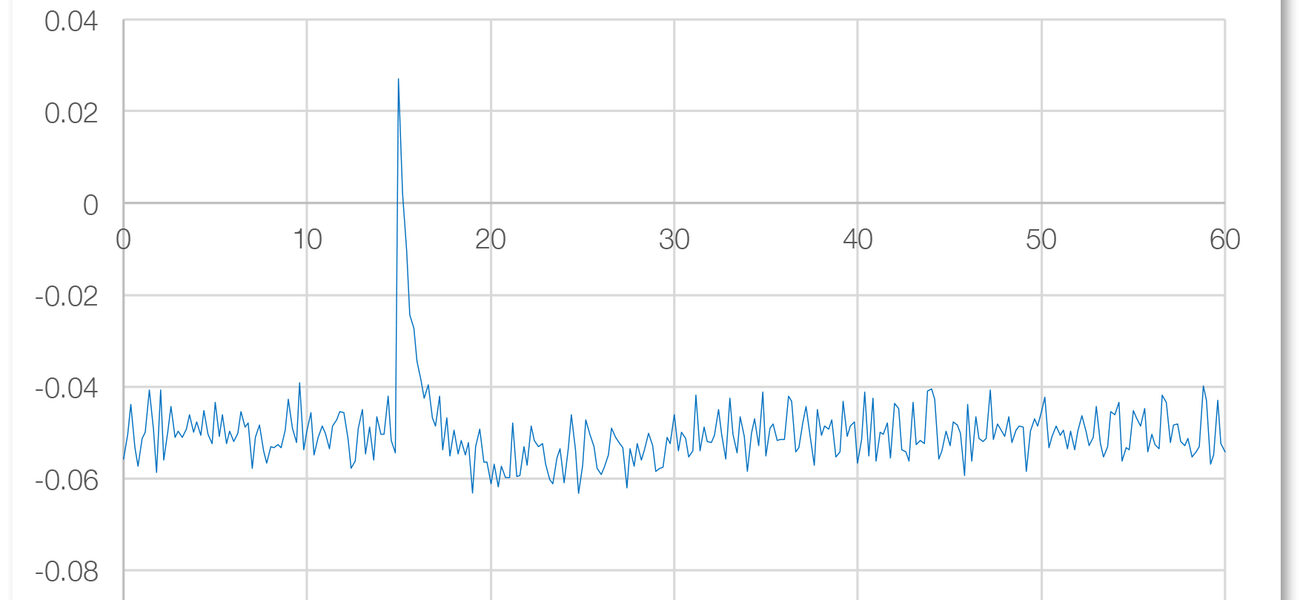

The results were compelling and revealed a much slower event response in the rooms with progressive offset control: longer recovery times (up to 12+ seconds) with either turbulent or laminar transfer air. Recovery in the model with direct pressure control and an undercut door was markedly faster, down to 1.6 seconds, and even faster with the same control scheme and an engineered opening (1.4 seconds).

Also, direct pressure control reduced the nominal fluctuations of room pressure, indicating increased overall control stability.

Mixed Control Scheme: A Better Option

While the findings indicate that direct pressure control is the better choice, it’s rarely used, often because of the overestimated complexity and costs.

“Progressive offset control is perceived as simpler, but it’s not,” explains Clements. “There are many more steps in the control logic when compared to direct pressure control.”

“Direct pressure requires specialized knowledge to implement, but is within the skillset of typical lab technicians. Also—and this applies to any enhanced control strategy—door sensors and fast-acting actuators are needed to ensure the system works across all of its intended operating modes,” says Clements.

The engineers pointedly note that in some cases, as in BSL-2 labs or BSL-3 labs that don’t work with select agents, the enhanced control offered by direct pressure may not be necessary.

“You have to ask if it’s worth the complexity, because it requires a higher level of expertise from the controls contractor and technicians, which often aren’t the lowest bidders.”

Based on their study, Clements and Stanford have come up with a novel solution: a mix of progressive offset and direct pressure controls. Somewhat of a middle ground, this concept considers the differing performance profiles in the various space types in the containment suite.

“We typically don’t see a mix of different control strategies in a containment suite,” says Clements. “But the question to ask is: what’s best for the particular room? A space is only as stable as its neighbors. Rooms are typically connected by undercut doors, or engineered openings, so if one space has a problem, the adjacent rooms will also experience the problem. Dead-end spaces—rooms with only one door—will have a minimal effect on room pressures within a suite. But unstable corridors and other bridging spaces will affect all contiguous spaces, like a bad hub affects the spokes on a wheel.”

With its connections to all spaces, the corridor has a pivotal role to play in the containment strategy for the entire suite. Often regarded as least important, because it does not house primary research, the corridor (or similar anchor space) is actually the hub. “It’s inherently a central anchor from the control standpoint,” according to Clements. “This is a new way of looking at the corridor.”

It follows that equipping the corridor with the higher performance of a direct pressure control system would enhance containment capabilities of the suite as a whole.

“Under direct control, if something happens in a lab, the corridor acts as a workhorse, absorbing, minimizing, or mitigating pressure fluctuations. The other rooms aren’t affected, and the problem doesn’t propagate,” explains Stanford.

A further potential enhancement is a primary-secondary valve configuration for corridor supply air. The larger secondary valve provides the requisite air volume, while the smaller primary valve enables fine-tuning for space pressure control.

With the corridor under direct control, the other rooms in the suite can operate effectively under progressive offset control. Clements and Stanford point out that the mix of control types should be systematic throughout the facility, with all procedure rooms operating one way, and all corridors another.

Project Roadmap

Clements and Stanford have compiled their findings in a project roadmap, which serves as a quick guide to find the best control strategy for achieving stability in specific types of labs, complete with updated design guidelines.

“The roadmap is a handy reference for work on a new or renovated facility, or to identify why an issue has surfaced in an existing facility,” says Clements. “In all our modeling and simulations, we have accounted for the components that are essential, while still being cost effective.”

“You absolutely can have it all: stable control and rapid response. Our research proves that combining an enhanced controls strategy with laminar transfer airflow solves the pressure control problem,” concludes Stanford.

By Nicole Zaro Stahl