Eli Lilly and Company embarked on a year-long process to create a new collaborative and flexible space model dubbed CoLAB. In order to achieve the flexibility they aim for, Lilly is employing the use of ceiling infrastructure and innovative fume hoods, the design of which ultimately saved hundreds of thousands of dollars. CoLAB’s purpose is to collocate previously separated groups into a new research campus, specifically stressing collaboration, innovation, and speed-to-market of new therapies. The initiative is designed to address constraints caused by both geographic separation and aging facilities in the Small Molecule Design and Development (SMDD) organization, the group that is responsible for the scale-up work that acts as the bridge between research and manufacturing.

Stan Lengerich, C.I.H., senior research scientist at Lilly, stresses that the 10 design directives that created CoLAB—including collaboration, flexibility, and transparency—are not just “nice platitudes.” Each of them has been incorporated into a legally binding document referred to as “conditions of satisfaction,” which will be used to evaluate performance both at facility completion and for post-occupancy surveys.

Encouraging Collaboration

While there have been a few flexible lab pilot projects at Lilly, CoLAB will be the company’s first full-scale facility that utilizes an entirely open approach.

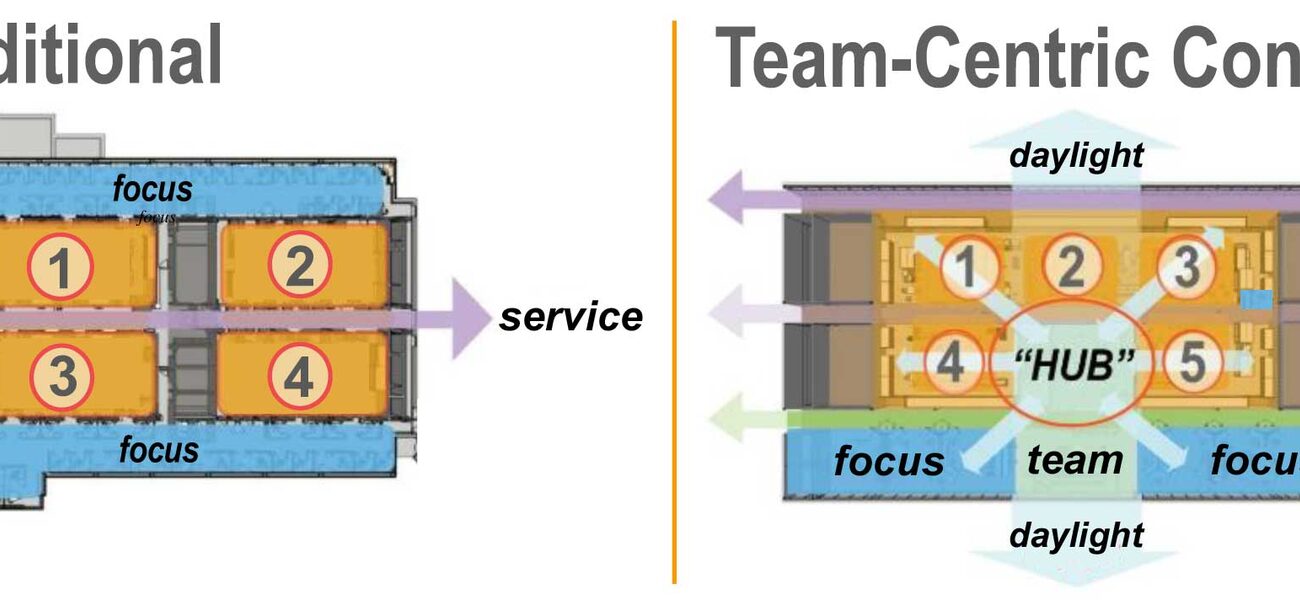

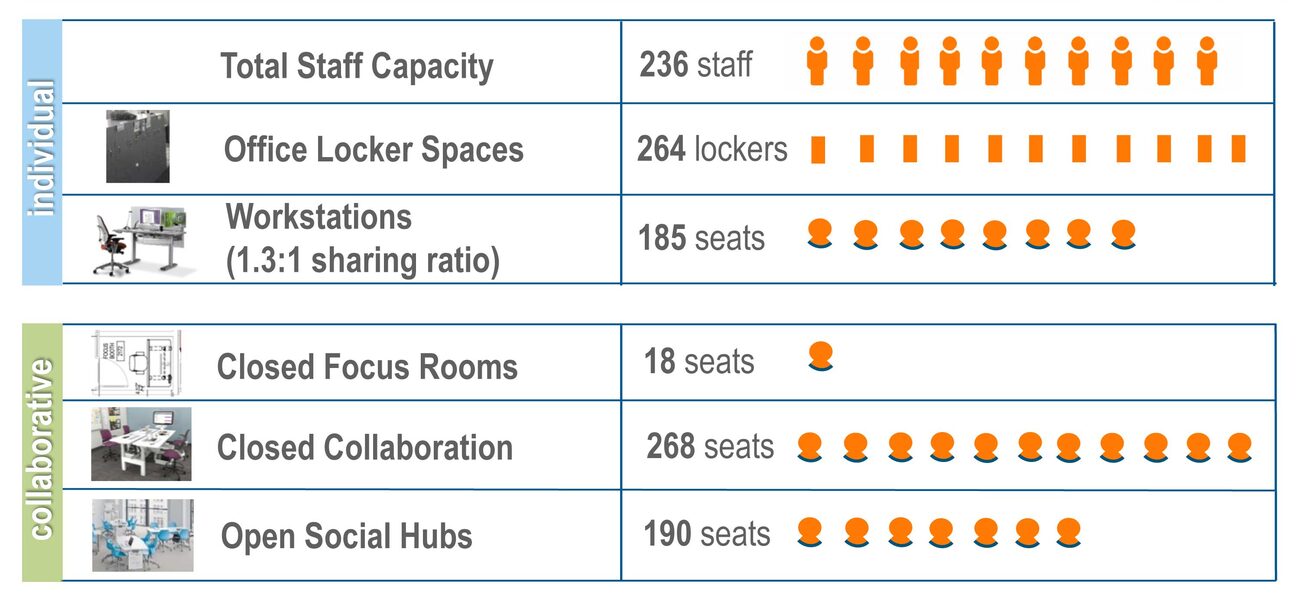

There are no assigned workstations in the office area, regardless of rank, even at the VP level. Employees can sit anywhere they like, but there are 185 desks for a staff of up to 236 people—1.3 people to every one workstation. Actual space allotment, however, is 163 sf per person, so this shared workspace was not intended to be a space-saving strategy. “If it were,” says Marc Walker, Flad’s project architect, “we wouldn’t have all of these other spaces, such as the focus rooms, the closed collaboration spaces with 30 seats, and the social hubs with a lot more seats.” Instead, these collaboration spaces are intended to maximize the crossing of paths between departments.

“By also carving strategically placed collaboration areas into valuable lab space, scientists will be able to meet and share data without having to leave the lab, which maximizes their time spent in the lab, and tends to be the most productive time,” he says.

Lilly also encourages collaboration with the ability to access all labs on all floors without the removal of personal protective equipment (PPE). All personnel are required to wear PPE in the lab and remove it when they leave; in a building with many labs on many floors, this can be time-consuming and wasteful. Now, there are corridors, stairs, and elevators connecting every lab on every floor, removing this nuisance and increasing efficiency.

“I think this is destined to be a user favorite,” says Lengerich.

Adaptable Infrastructure

One of Lilly’s primary infrastructure strategies is the use of pre-assembled modules (PAMs) for the majority of utilities. “PAMs are essential building blocks for creating the agile infrastructure that is required for a truly flexible lab facility,” says Kevin McNutt, senior mechanical engineer from BSA Life Structures. While PAMs are not unique to Lilly, they have not been widely used in new lab facilities. At Lilly, these modular MEP infrastructure units range from 40 to 60 feet in length and they are spaced 22 feet on center for the full length of the lab. The PAMs carry exhaust air, lab gases, water, electrical bus ducts, and cable trays. Designed with utility taps and valves every 8 feet, for quick connection to any utility and spare exhaust connections along the length of the duct, the PAMS are able to rapidly accommodate ever-changing utility requirements. Because they were built off site, they drastically increase on-site safety during construction, and have saved about 3,000 on-site labor hours.

Below the PAMs is a structural grid of highly engineered aluminum beams installed 10 feet above the floor. The grid works as a faux-ceiling that doubles as a mount for hanging equipment and some types of casework. In addition to lighting, the grid contains the ceiling interface panels (CIPs) that carry electrical receptacles, fluid connections, and data jacks for casework and associated instruments below. This grid system is space-efficient, and allows for local flexibility and fast reconfiguration.

Traditionally at Eli Lilly, waste solvent sinks piped to a collection tank have been located at each fume hood, but with newer EPA regulations, this is nearly impossible, both logistically and financially. Instead, Lilly has opted for solvent dumping sinks in four key locations per floor; each is ventilated and intended for both disposing of solvents and rinsing glassware. For aqueous waste, a series of hub drains run throughout the lab on an 11-sf grid, which can be tapped into when needed during equipment relocation.

Fume Hoods

Some might argue that fume hoods are “on their way out” due to the rapid advancement of options such as virtual chemistry and computational modeling. Lengerich points out that, while this may be true, most researchers at Lilly and elsewhere still rely heavily on them and will continue to for the foreseeable future. In fact, Lilly is implementing innovative spins on the classic fume hood. For one, under the CoLAB model, fume hoods are not dedicated to the individual, but are allotted based on specific projects and their needs, resulting in a ratio of about 1.5 hoods per person. While most buildings are equipped with the traditional bench-top hoods, at Lilly, the scale of the SMDD operations is large enough that greater than 80 percent of hoods are floor-mounted, (aka: walk-in) fume hoods. The floor-mounted and bench-top hoods share many of the same features, such as onboard circuit-breakers and an emergency stop button to de-energize receptacles inside the hood.

A variable air volume HVAC system typically has the capacity for 70 or 80 percent of the fume hood sashes to be open simultaneously. Lilly’s design is unusual in that the company estimates that no more than 50 percent of its researchers will be operating their hoods at any given time. At a low-flow capture rate of 70 feet per minute, coupled with a fume hood usage diversity of 50 percent, the design lowers energy consumption and operating cost along with a reduced first cost.

“We decided to push the envelope on this project,” says Lengerich. “The need for fume hoods is not expected to ever increase, only to decrease.”

The benchtop hoods also have breakthrough features offering easily accessible working parts, making them more flexible. First, they are mounted independently on frames to allow for shifting of storage cabinets and other support equipment under the hood. Cabinets for hazardous material storage can be easily connected to ventilation piping routed behind the baffles and into the exhaust takeoffs, which capitalizes on where the static pressure is the greatest. In order to route equipment cords, cables, and tubing, pass-throughs on the hoods are also equipped with a design modification that offers a “subtle but critical touch,” as Lengerich calls it. The bottom pass-through has a T-shaped design so that the cables and tubing connecting equipment below the work surface can be easily routed down into that space, which makes it much more convenient for scientists setting up support equipment. “Sometimes it’s the little details that make the big difference,” explains Lengerich.

The walk-in fume hoods feature a combination sliding/hinged door that allows it to open completely, obviating the need to stick-build large, continuous-processing rigs inside the hood. “Having a larger opening in the hood greatly facilitates building the carts elsewhere and rolling them into place,” says Lengerich. “They open very quickly, very efficiently, very easily. Our scientists absolutely love this feature, and although I am not entirely sure, it may be the first time combination hinged and sliding doors have ever been used, or at least used on this scale.”

In addition to the increased accessibility, the walk-in hoods are also designed to be highly moveable, including a removable stainless steel floor pan, which contains spills. Doorways within the labs are extra tall to allow for easy passage, but an elevator with those dimensions would have incurred a cost premium well over $300,000. The solution was to ask Mott about making hoods with a removable crown. “Because of the onboard breaker panels and modular utility feeds, this was a fairly straightforward process,” says Lengerich. This adaptability of the fume hoods was able to save an estimated $265,000.

Of course the most important feature of a fume hood is its containment capability, and Lilly’s testing of these hoods went above and beyond standard protocols, including ASHRAE 110 tracer gas testing, with multiple iterations of multiple sash configurations over six days, in addition to many protocols beyond the standard ASHRAE 100.

“But, we didn’t stop there,” says Lengerich. “We took it to the next step and conducted process simulations with surrogate powder and collected air samples in the breathing zone of the users. We conducted multiple steps with multiple people for four days. In total, we spent two weeks and at least $65,000 doing the testing, and that is just checks out the door. That doesn’t account for anybody’s time.”

On top of that, every hood—all 124—will receive full ASHRAE 110 testing after they have been installed in the building.

“So far, I am happy to report that we have gotten really good results, really good containment with these hoods,” he says.

By Anita Woofenden