Microvivaria—customized, small-scale animal research environments, built within an existing building or as new construction—are a good option when research needs dictate a smaller, more focused facility; when a location is not viable for, or proximate to, a full-scale vivarium; or when speed to uptime is key. They are equal to their full-size counterparts in virtually all aspects, including building and structural requirements and materials, operational strategies and systems, and compliance with industry standards and fundamentals governing proper animal health and experimental conditions.

“All the same principles that apply to a large vivarium, also apply to a small vivarium. You do all the same things, but on a smaller scale,” says Erik Mollo-Christensen, AIA, a principal with Tsoi/Kobus & Associates. “You won’t necessarily save money building a microvivarium, since unit costs are similar or slightly higher, but you have the economy of building only what you need.”

Microvivaria—some as small as 250 sf—are fully contained units, not modular, and are built either as new construction or within existing science space; most use available utilities and material pathways. Designed for small or very specific research needs, they can house animals for more than 24 hours and generally do not have cage washing on site. Microvivaria optimize infrastructure expenses for institutions facing decreased capital funding and grants due to institutional consolidation, and meet a growing need for specialized, localized research.

“With a decrease in funding, there is less ability to construct and operate a large, permanent, vivarium,” says Mollo-Christensen. “Some facilities have a modest need for animal research; they do not need a full vivarium.”

Essential vs. Optional Functions

Whether the vivarium is full-size or “micro,” the same fundamental requirements for animal health apply, including care protocols, barrier conditions and containment, and material and animal flow. The essential functions include housing and caging space; procedure space, which is generally separated from housing space; layout and workflow, to maintain animal health; entry and exit for people, materials, and animals; support and/or storage space; accommodation for cleaning and sterilization; and reliable mechanical and electrical systems for 24-hour operation. “You don’t need a lot, but you have to have at least some of each of these functions,” says Tony Petone, principal at Bard, Rao + Athanas Consulting Engineers.

Optional functions include on-site cage washing and processing; on-site rack and cart washing; imaging; a dedicated necropsy room; staff support facilities, such as offices and lockers; and vivarium storage space. Petone and Mollo-Christensen do not recommend full cage washing and sterilization on site in the microvivarium, since the equipment is expensive and often comes with more capacity than is required for a smaller setup.

“If you are using cage-washing equipment for only a few hours a week, the cost is significant, so it is best to find other ways,” says Mollo-Christensen. Options include disposable cages, or sending cages elsewhere to be washed.

Generally, materials and construction are the same for both full-size and microvivaria, including drywall construction, epoxy paint for easy washing and decontamination, enclosed areas with sealed construction to maintain adequate pressurization and isolation/containment, and smooth corners and impact-resistant walls for optimal cart and material movement. Walls and ceilings have acoustic resistance to minimize sound transmission.

“There is not a big difference in the physical construction, but depending on the location, some factors may be challenging,” says Mollo-Christensen. For instance, if the vivarium is on an upper floor, it may be difficult to control floor vibration. Solutions include reinforcing the floor structure, using heavy-grade sheet vinyl rather than the urethane/epoxy or MMA flooring commonly used in a full vivarium, or building closer to the columns.

Controlling Air and Humidity

Microvivaria typically have fewer cages and generate less heat. However, controlling the relative humidity in animal holding rooms within the range of 30 to 70 percent, plus or minus 10 percent of the set point, (specified by The Guide for the Care and Use of Laboratory Animals: Eighth Edition), is more difficult when building in an existing facility where central humidification is less common, says Petone. Rather than installing central humidification systems to service just a few holding rooms, point-of-use humidifiers provide a more cost-effective and efficient option. So far, most microvivaria have been built to house mice, so it is not necessary to reach the higher humidity levels specified for larger animals, he says.

Maintaining room pressure differentials within the required standard of 10 to 15 air changes per hour can be challenging. If the microvivarium is within an existing lab environment, extending existing systems is generally effective and optimizes capital costs.

“Once you start doing dedicated systems, the project is not cost effective,” says Petone. Most microvivaria also use centralized systems for back-up power or animal ventilation.

“Since most of these lab buildings where we build microvivaria already have 8 to 12 air changes in their system, from a capacity perspective it is not a big deal to divert it into a room this size,” explains Mollo-Christensen.

Where Going Micro Works

The following three projects demonstrate situations where microvivaria work well. All are in buildings with adequate lab or clinic size, with house systems providing most of the air and power, and on-site emergency generators for back-up. Two sites are independent research organizations, one in a university setting and one in a hospital setting, that historically receive NIH funds for research. When continuous funding from NIH was less certain, they decided to build their own small-scale vivarium space. The cancer treatment facility identified a specific need for a small amount of ancillary space for radiotherapy research using animals.

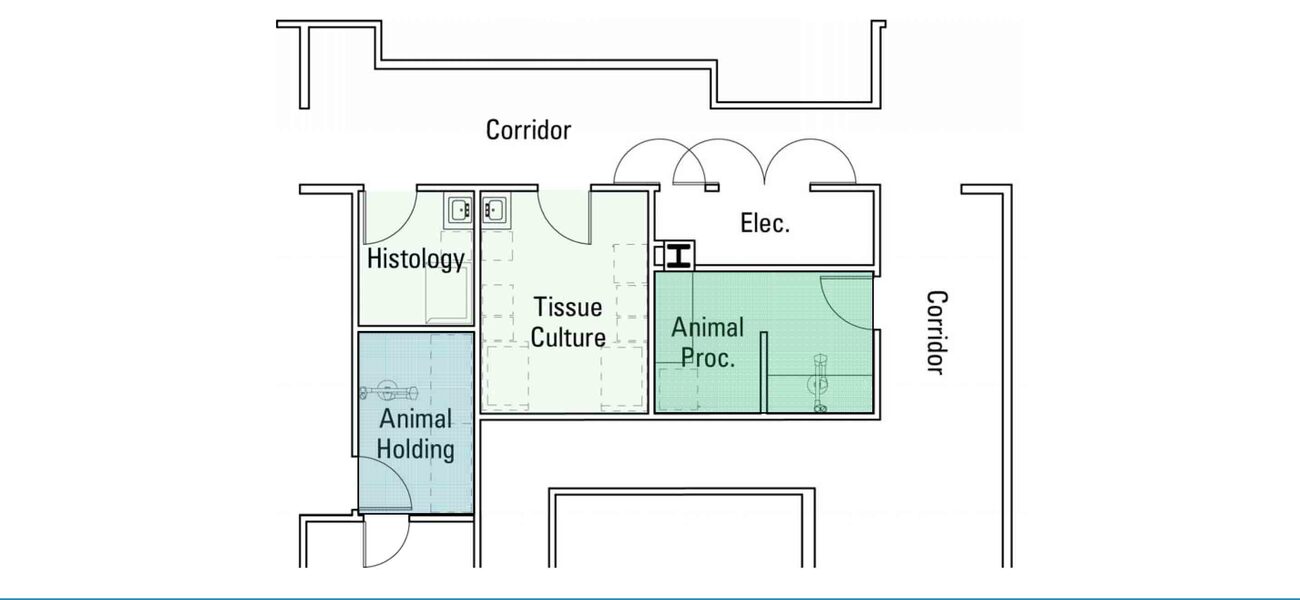

One independent research organization created a 250-sf microvivarium in order to run four- to six-week cardiology studies on rodents, involving 50 to 100 cages of rats brought in from another institution. The two-room suite has a single holding room that can accommodate two racks with disposable caging, and a single procedure room for animal transfer and minor procedures. Disposable cages eliminate the need for on-site cage processing; only surface decontamination of racks and room surfaces is needed. Staff enter the holding room directly from the corridor, where they can gown up before entering the suite. The suite has a dedicated AHU, with controlled back-up from the central system.

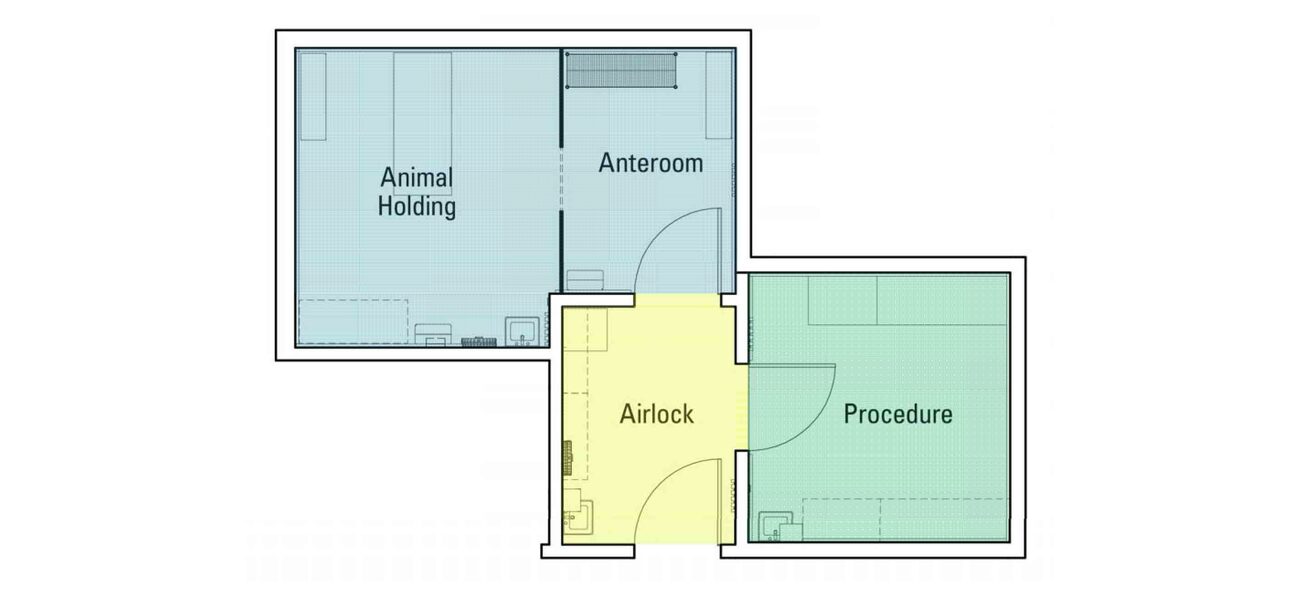

The outpatient cancer treatment is a 96,000-sf facility with a need to conduct four- to six-week radiotherapy studies on rodents. The project is unusual because the institution has plenty of vivarium space in other buildings, but needed just a very small space in this particular location. The solution is a bioBUBBLE enclosure, a plug-in micro-environment with a HEPA filter that creates and maintains barrier conditions. The 500-sf, two-room suite has a single holding room with racks inside the bubble, a single procedure room, and a single airlock for the transfer of people, animals, and material with PPE. “This is a very low-tech option in terms of design and construction,” says Mollo-Christensen. Since the rodents are delivered from a central location, and cages are returned to the central site for cleaning, no on-site cage washing is required.

The third case is a 3,000-sf microvivarium built in a new 189,000-sf satellite lab, where the parent organization resides in another state. The space consists of two small suites, with a total of five holding rooms that have capacity to operate as ABSL-1 or ABSL-2, depending on future research needs. There are three combined procedure and holding rooms, and space to accommodate several sterilizers or a sterilizer and a washer. “They anticipate using them for housing and procedures for certain kinds of studies, but they could separate them,” says Petone. Unlike the previous examples, the suite has dedicated AHUs and two exhaust fans, with dedicated controlled back-up from the house systems, and manual cage and rack washing.

“With these micro-scale facilities, we see that it is entirely possible to optimize space for a microvivarium at a reasonable cost. The MEP systems and the construction is practical on a small scale without any significant penalty, and it is entirely practical to comply with all the regulations and standards,” says Mollo-Christensen.

By Mary Beth Rohde