Paying a premium for the flexibility to remain truly generic can be both expensive and counterproductive to lab design goals, say the designers of the Wisconsin Institutes of Medical Research (WIMR) multi-phase project at the University of Wisconsin (UW). Instead, they increased space efficiency and density by walking a fine line between custom and generic lab design, with a modular framework that met certain parameters but could be adapted to the science conducted within the spaces.

“The truly generic, flexible lab, I would contend, is a myth. Science is not generic,” says Elizabeth Domoracki, facilities architect at the UW School of Medicine and Public Health.

“You can spend a lot of money preparing for the future by purchasing ‘flexible’ equipment that may never be used,” adds Mark Wells, assistant dean for facilities at UW School of Medicine and Public Health. “If a particular lab can’t do its work, it’s a failure all around. It’s also a failure if you blow your budget, which would happen if you created a completely generic lab and had to make lots of changes.”

Acting upon lessons learned post occupancy from WIMR 1—and a request to include more lab space in the same footprint—the design team utilized “informed lab planning” when developing the second of the three-phase WIMR project. Informed lab planning involves capturing individual lab and support space needs upfront before customizing the modular framework. The result is a more cost-effective, streamlined design that should not need expensive alterations in the future.

“The ‘generic’ design is appropriate, because things change,” says Wells. “It is a huge mistake from a building owner’s perspective to give complete design control over to the scientists; if you do so, you usually end up with a ‘rabbit warren,’ because everybody gets focused at the micro level with doing their own thing. But, it’s also a big mistake if you stick strictly to a generic building and just say, ‘move in.’ Then you have lots of problems, because it doesn’t meet specific needs.

“The smarter thing is to focus on the science going on in that particular area, talk to the people you know are moving in, and get specifics as to how their workflow occurs,” he says. “What we did is capture the details before we built it.”

Learning from Experience

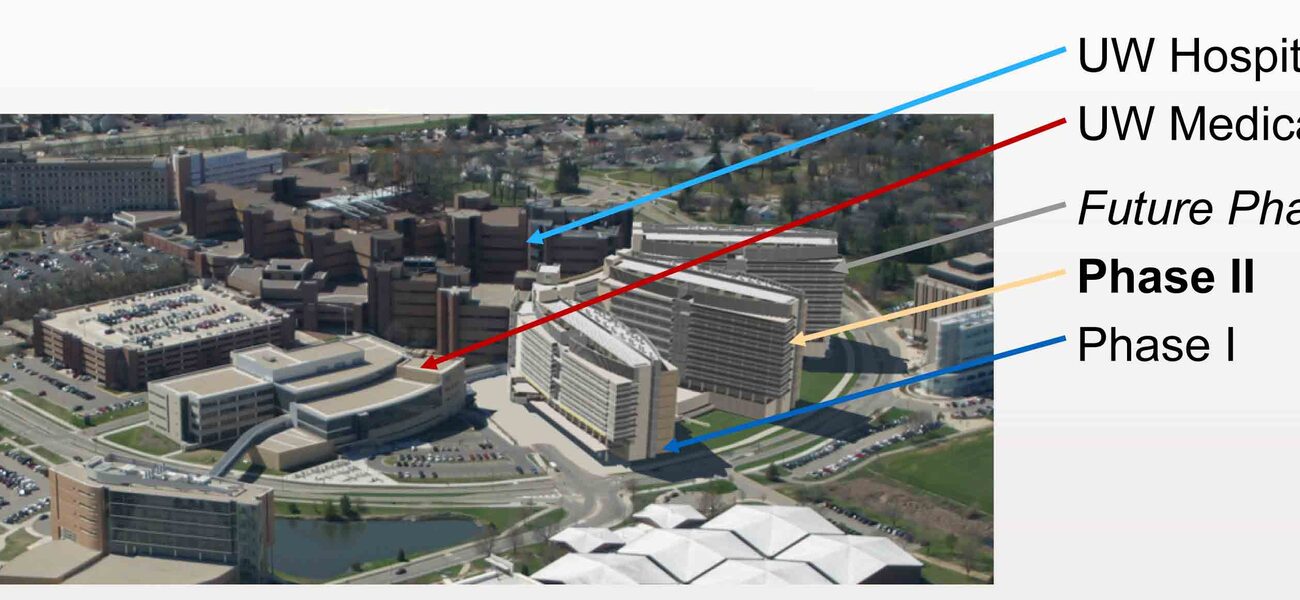

The WIMR project is a 711,000 gsf, $313 million lab facility that will house basic and clinical scientists in the fields of cancer and cardiovascular research, regenerative and molecular medicine, neuroscience and developmental biology, imaging, and animal research. The seven-story, 453,000-gsf Phase 1 east tower and plinth opened in 2009, and its design set the basis for the rest of the project.

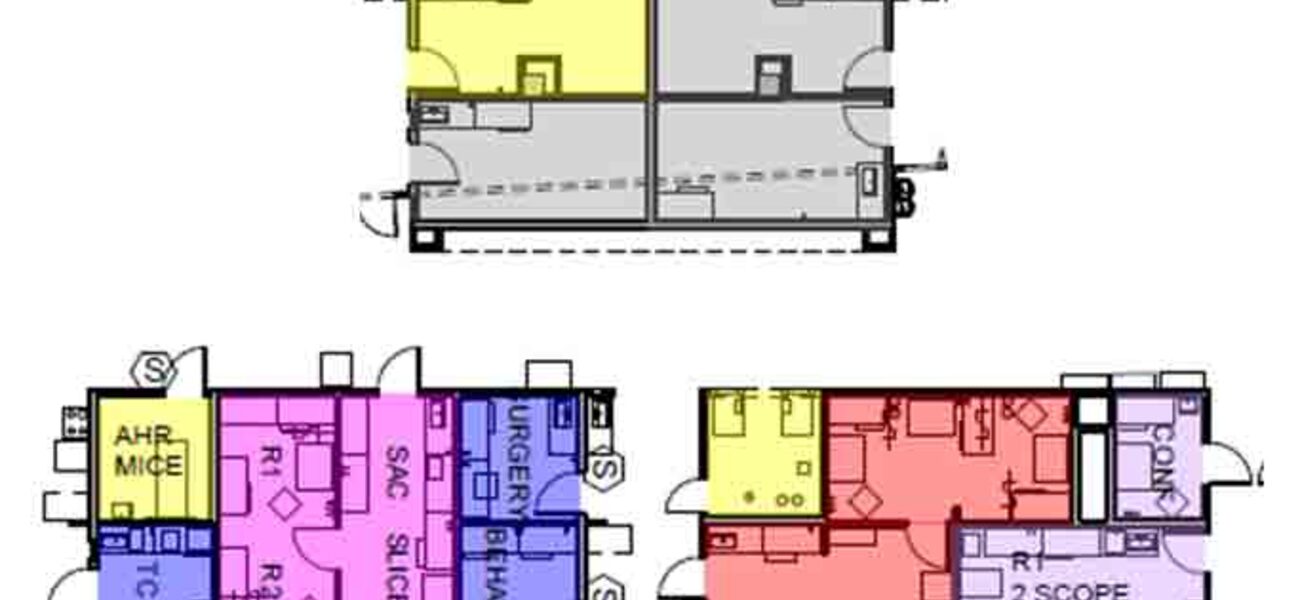

The first tower follows a generic floor plan as a baseline for the project’s guaranteed maximum price. The document spells out the plan and design of each identical lab floor, types of lab support rooms and their locations, the number and type of equipment provided, and the count and location of plumbing and other critical services. The tower houses the University of Wisconsin Carbone Cancer Center and the departments of surgery, medical physics, orthopedics and rehabilitation, and radiology, which assigned principal investigators (PIs) to spaces by dividing the floor plate equally among researchers.

To avoid construction delay, lab planning coincided with physical construction, and money was set aside for tenant improvements, explains Wells. Lab floors were completed and then immediately renovated to accommodate the specific science of the tenant.

A post-occupancy survey conducted soon after researchers moved in noted several design concerns:

- Generally, lab occupants did not like the office cubicles and the limited amount of enclosed wet lab support space outside of the main lab.

- The open lab plan—designed to foster communication between research labs and to expand and contract in place over time—generally worked well, however, various cancer lab functions must be conducted behind closed doors for personnel and product safety.

- Due to the equal distribution of space, irrespective of lab group size or science, some lab groups didn’t have enough of these private spaces, while others had too many.

- The only vertical circulation on the football-field-long floor plate was one stairwell at each end.

The lab floor design also removed the PI and lab staff offices from the lab entirely, and created a sea of furniture-partitioned cubicles for grad students and post-doc trainees, says Wells. “While this made for a nice place to sit and eat lunch away from the lab, the confinement of the cubicles and their distance from the lab work was counterproductive in fostering the interdisciplinary collaboration the open lab was intended to provide. It took all of the activity from the labs and hid it behind furniture panels, leaving the floors feeling very sparsely populated.”

Near the end of Phase 1, the School of Medicine dean asked for more lab space, as well. “Taking into account the feedback from the post-occupancy evaluation, we vastly improved upon it,” adds Wells.

Improving the Design Within the Same Framework

Since WIMR Phase 2 had to use the same foundations and structural framework as Phase 1, the design team needed to improve space efficiency by redesigning the interior partition layout. They eliminated one of the cross passages to gain more enclosed wet lab support rooms, says Wells.

They eliminated the cubicles from the dry office side by adding desks in the open lab area, creating an additional 15 percent of wet lab support per floor.

“Because we added so much density to the open lab, we were able to use the desk portion of the lab as flexible bench space. Some labs actually filled this with stand-up-height benches for maximum flexibility. For safety, all eating and drinking breaks occur outside the lab,” says Wells.

The final improvement to the layout involved creating the modular plan that could expand or contract to accommodate a variety of sciences. The grid’s basic building block is a 10-by-10-foot space. Since that size alone would not accommodate the neurophysiology research slated to be done there, the framework allows for expansion in increments of 10 by 10, to a maximum 30-by-40-foot area, four on each floor.

“In the exact same footprint, Phase 2 holds more active lab space per floor than Phase 1,” notes Domoracki.

By also utilizing the building’s vertical mezzanine space, the design team accommodated 60 percent more people in WIMR 2 than the first tower, and provided spaces for people to interact out of the lab in a collaborative setting.

“The concept of a mezzanine was very contentious at the outset. We didn’t know how it would physically work with our existing structure and foundations; we didn’t know who would sit there, or how it would feel to be so remote. Turns out, it’s the best space on the floor,” says Domoracki.

Reworking the mezzanine space presented challenges. Headroom requirements meant they had to change that section of the building’s structure to steel framing, as opposed to the concrete used in Phase 1. This saved significant cost and construction time, adds Domoracki, but they had to carefully configure the HVAC distribution to the mezzanine and the offices below, in order to maintain those same requirements. A mezzanine cannot be larger than 49 percent of its floor area below, so they had to keep the space within that range.

“In the end, we designed openings in the web of the beams to take advantage of as many inches of vertical space as possible,” she said.

Informed Design

Informed design planning worked for WIMR Phase 2 because university leadership identified specific tenant groups up front who practiced complementary science, and assigned them to specific floors. Domoracki then met with every PI and lab group over the course of 10 months.

She took an inventory of their large equipment, and asked about their processes and if they shared equipment or collaborated with other PIs. “We then made some assumptions about the number of ‘units’ of space each lab group would require in the new tower, if they could share with their neighbors, and who those neighbors would be. Instead of assigning each lab group the metric-driven 1,200 sf, we took a significant amount of time to validate their actual needs.

“The result was 250,000 sf of 100 percent customized lab space; we planned the spaces and the systems around the science. Space for future recruitments remained generic based on the science.”

Throughout this planning stage, the researchers were told only about their assigned floor and the generic footprint, never exactly where they would be located. “Essentially, we asked them to trust us,” says Domoracki.

The vagueness was necessary because the custom planning was going to take a long time, and they didn’t want to lock anyone into a space until the best fits and adjacencies were determined, she adds.

“Once unveiled, the results were spectacular. Within the first two weeks of inhabiting the new facility, I had three PIs tell me that they were realizing collaborations with nearby labs and were planning to launch new studies with collaborative scientific outcomes.

“We achieved efficiencies in planning by identifying overlaps in function and use, and encouraging the use of shared equipment and lab support spaces. We created more density by assigning people efficiently to the spaces they use and not the spaces they want, or to which they felt entitled.”

Flexibility and Future-Proofing

Creating a modular framework not only aided the planning of the second WIMR tower, but also UW’s planning for future flexibility and renovation in this 50-year facility.

Even though they have customized the framework to a point, they have created different kinds of similar spaces on top of it, so they shouldn’t have much difficulty creating new spaces using the same framework, says Domoracki.

A truly generic, flexible lab would have required more outlets, data, and power in order to be prepared for any possibility. “Flexible” spaces often include features such as benches that are movable and height-adjustable. Phase 1 of WIMR had some of these features, but the design team looked at whether or not they were actually used, says Wells. At the most, two benches were ever moved, and he doesn’t believe any were adjusted for height.

The design team kept removable benches in Phase 2 because they felt it was still worth the cost, says Wells. But adjustable benches were not worth the cost, he adds. “If we ever needed to switch them out, we would probably have one readily available in inventory—we’re going to have flexibility in terms of our inventory.”

The post-occupancy review also showed that cupsinks inside of chemical fume hoods weren’t being used, so they were removed from Phase 2, and the number of hoods was reduced.

“We saved a lot of money by being observant,” notes Wells.

“And we put that effort and funding into individuation of the labs,” adds Domoracki.

With the final WIMR phase, the design team will continue to build upon the lessons they learned: With a little effort and thinking outside of the box, you can increase lab capacity and personnel density in the same footprint; and an informed approach to lab planning can saved money and make for very happy faculty.

“It’s not difficult to imagine the improvements we will make to the final phase of WIMR, when we have no restrictions in foundation capacity or footprint,” concludes Wells. “We will follow the same steps from Phase 2. Our experience has taught us to be thoughtful and deliberate in our planning, because we’ve proven that we achieve our best results from an informed approach to planning.”

By Taitia Shelow

This article is based on a presentation Wells and Domoracki made at Tradeline’s Research Facilities 2015 conference.