Flexibility is paramount in any research facility, but particularly in nanotechnology, which is evolving so quickly that a design can become outdated by the time construction is complete. Nanotechnology facilities also present unique requirements with their sensitive equipment and cleanrooms. Overcoming these challenges requires a robust structure and an acute understanding of how people and materials flow through the building.

“We no longer think about buildings as static objects. Instead, we focus on the constant change within a building,” says F. Jeffrey Murray, director of design for IDC Architects in Pittsburgh. “Research is changing before a building is even finished the first time, so it is important that the structure meets the spatial requirements and optimizes the needs of the science, rather than configuring the space to fit an optimized structural system.”

The potential applications for nanoscience are enormous, with advances in nanoelectronics, biotechnology, and nanotechnology, including focused drug delivery, biological and chemical sensors, ultra-lightweight materials, supercomputing, and advanced consumer products. Many everyday products are created with nanotechnology, including most smart phones and tablets, information storage systems, blood monitoring systems, hospital patient monitors, sunscreens, skin lotions, automotive brake sensors, and carbon nanotube metals.

The highly specialized research requires facilities that are technically complex to accommodate elaborate and sensitive equipment, and socially complex to foster interdisciplinary collaboration. Properly designing a facility with an understanding of the concept of “flow” can ultimately reduce operating costs and the need to make structural changes as research evolves, says Murray.

Understanding the Dynamics of Flow

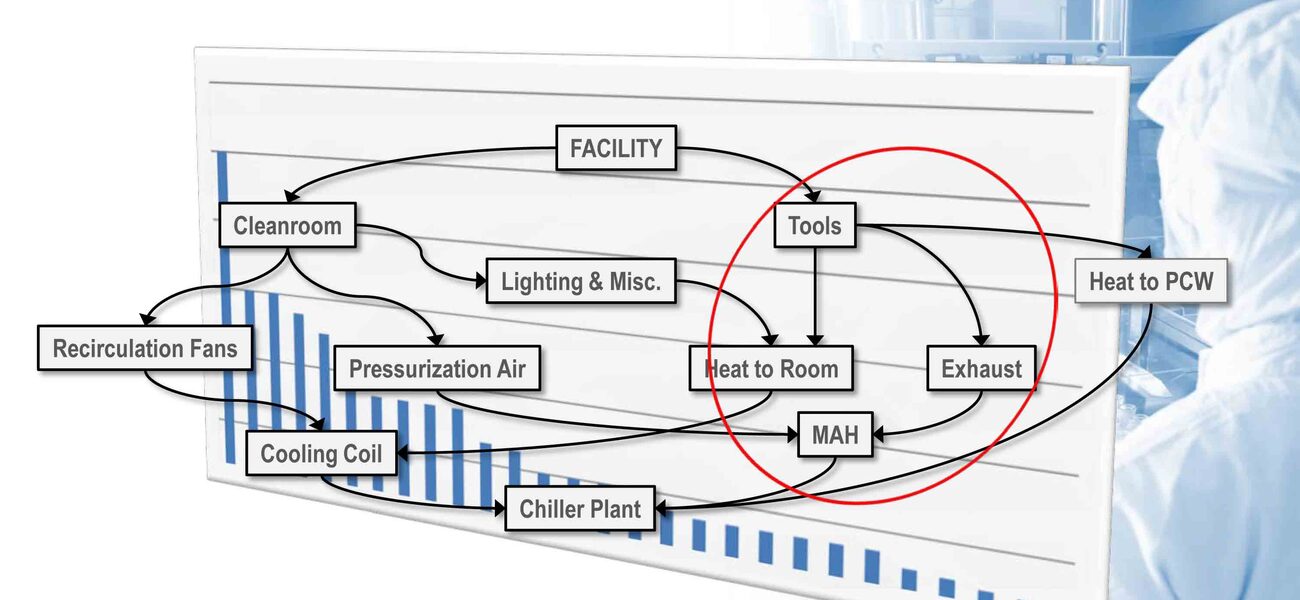

There are many flow systems within a building: Energy efficiency in the building envelope can be seen in relation to the flow of heat and cold; HVAC systems control the flow of ventilated air; lighting systems channel the flow of natural and artificial light; communication systems manage the flow of electronic information; plumbing systems direct the flow of liquids; aesthetics define the flow of attention through a visual field; design is the flow of ideas; and experience is the flow of people through space. The structure itself, which represents the flow of stresses through supported and supporting elements, is the framework that channels the flow of all systems.

Murray breaks the concept down into technical flows and experiential flows. Technical flows include things like the mechanical systems (the flow of air and water in buildings); electrical systems (the flow of power); and building envelopes (the flow of wind, daylight, and precipitation from outside to inside).

“What we typically call functionality (how space enables human activities) and aesthetics (how space enables feelings and meaning) are really interwoven experiences and should not be conceptually separated, as is commonly done,” says Murray. “I try to avoid speaking of function and form and prefer to speak of experience as the synthesis of both. I like the idea of redefining building design as human/environment interaction.”

Space is a medium of flow, and even small changes in spatial flow can radically change the utilization and experience of a building. It is critical to consider spatial flows in a nanotechnology facility at the beginning of a construction or retrofitting project to avoid wasting space and encountering problems when users move into the building.

“It begins by focusing on the space needed to allow flows to occur both initially and in possible future situations,” says Murray. “A focus purely on the physical and technical aspects of a building can often lead to misunderstandings about how the space either facilitates or inhibits flow.”

Moving a door, for example, is a minor action from a technical perspective, but it can completely change the nature of how people and things move.

When considering flow in a nanotechnology facility, many factors must be taken into account, including electromagnetic interference with sensitive equipment, cleanliness, vibration, temperature and humidity control, adaptive HVAC zones, airborne molecular contamination, and acoustics. The movement of people, chemicals, and other materials is critical.

Benefits of a Robust Structure

A robust structure is fundamental to a productive, successful nanotechnology research facility, particularly with the sensitive equipment it contains. Structure is one of the most difficult things to change in the future, so it is important to invest in getting it right the first time. Structure defines space, so it should be designed to meet the spatial requirements rather than configuring the space to fit the structure. Upfront planning should be done to ensure spatial flexibility for planning and changing in the future and to guarantee the building meets the necessary criteria for vibration levels, acoustics, and other guidelines.

“Sensitivities for equipment functioning at or near atomic levels demand significant vibration and acoustic control, while maintaining a high level of utility quality and control, including an ever-increasing operator complexity with greater levels of safety protection,” notes Monty Stranski, an industrial engineer with CH2M Hill in Portland, Oregon. “Planning for nanotechnology equipment requires an array of solutions for cleanroom flexibility, electromechanical interference controls, sound and acoustic shielding, strict temperature and humidity controls, and structural vibration protections, including isolation of normal building systems.”

Achieving Spatial Organization and Flexibility

Understanding spatial needs begins with knowing a company’s mission, goals, and values. The design must be approached by considering spatial organization first and recognizing that the building systems serve that space.

Stranski and Murray cite an example where a client’s outdated building had offices for each of the researchers in the labs. Initially, the researchers wanted the same setup in their new facility, but the company wanted to improve collaboration between research groups. This goal led to a design grouping offices together, near but not in the labs, causing researchers to leave their lab areas more often. The path between the labs and offices was then designed with features that facilitate collaboration.

“The company recognized that this new spatial arrangement might lead to some tradeoffs in perceived efficiency, but felt that the increase in interaction opportunities was more important to the goal of scientific discovery,” says Murray. “After identifying key social and operational goals, we built some space models, as opposed to technical models, that allow all of the stakeholders to see how different alternatives might achieve those goals.”

Spatial flexibility in a nanotechnology facility is just as important as spatial organization, and there are several approaches, including modular space planning. For example, the lab space module defines ways for small spatial units to be nested together and allows for relatively easy reconfiguration. The small unit is typically defined by the standard human activities that need to take place and the equipment and services necessary to support those activities.

Another common approach involves using modular elements and systems, including modular wall systems, benching and furniture, ductwork, and overhead service panels.

One expensive way to be flexible is to bring every possible lab service to every possible station, to account for any scenario. An alternative is to pipe all of the services down the hallway with pre-installed valves for future extension into a lab when, and if, it becomes necessary. This more affordable approach requires allowing adequate space to install pipe runs in the future.

Incorporating Sustainability into Nanotechnology Facilities

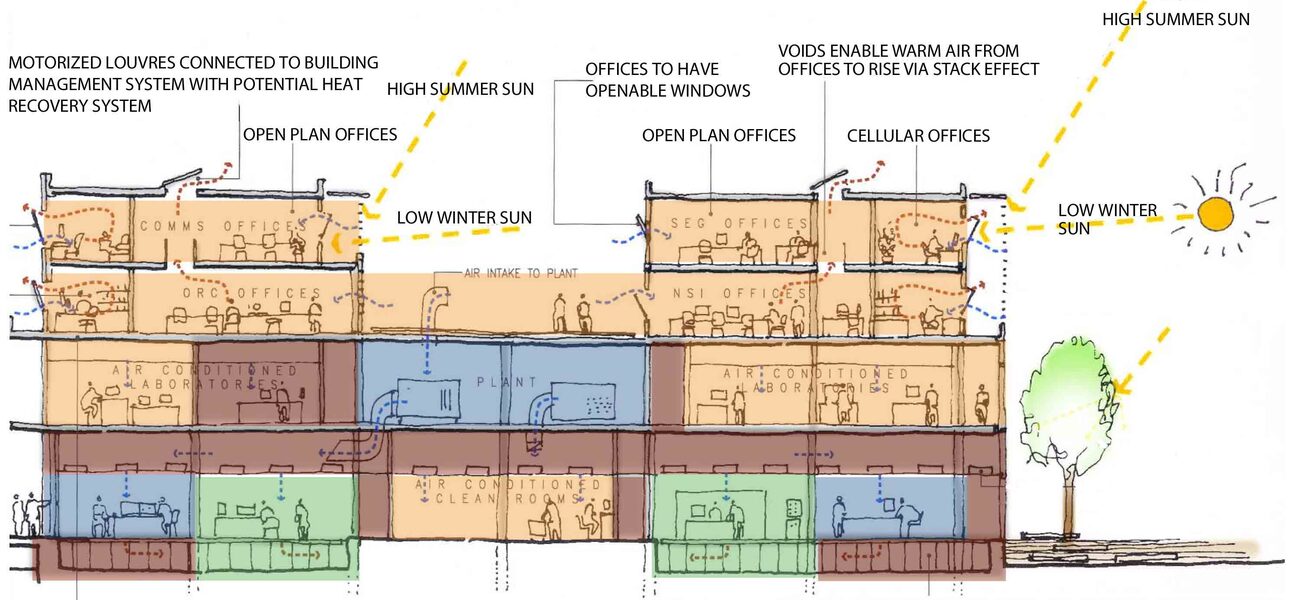

Highly specialized nanotechnology facilities do not have to sacrifice sustainability to achieve their structural or operational requirements. The Mountbatten Nanotechnology Electronics Research Complex on the campus of the University of Southampton is a prime example of a newly constructed facility that features sustainable amenities. The $90 million project, completed in 2009, has radiant heating and cooling pipes embedded in the concrete structure, natural ventilation stacks, and offices that are completely separated from the cleanroom areas.

Stranski says university officials required several research organizations to be housed in the new laboratory, creating a wide-ranging set of advanced research with critical microscopy, including electron beam, transmission electron, and atomic force equipment systems located close to laboratory neighbors who emit vibration and electromagnetic interference.

“Our approach for the design encompassed significant planning of all laboratory equipment for heat and air management, sensitivities, and operational requirements,” adds Stranski. “Additionally, advanced ventilation to attain effective make-up air and cooling strategies for sustainable practices were a major focus.”

A significant feature is the centrally located air handling units that shortened the pipe and duct runs to the specialized environments, reducing both first costs and operational expenses. Makeup air is pulled in through vents in a roof garden over the air handlers.

The Mountbatten project demonstrates how complex facilities can be designed around instrumentation, process, and specialized tools that require specialized environments, while at the same time incorporating energy-efficient features.

By Tracy Carbasho

This report is based on a presentation given by Murray and Stranski at Tradeline’s 2013 International Conference on Research Facilities.