Using a verification planning process to meet current regulations—for directional airflow, atmospheric pressure reference, containment barriers, and other common compliance measures—with solutions based on risk analysis and standard operating procedures (SOPs), takes a project through planning and design to fully licensed and operational, and helps minimize spending on solutions to a level that is risk-appropriate.

There is a tendency to assume the worst-case scenario in the funding phase of project planning, since this assumption avoids budget shortfalls if expensive problems related to compliance arise, says Michael Clements, former business development manager at Merrick & Company.

“In these very complex facilities, there are often complex issues with no obvious solution,” he says. “Addressing compliance by throwing capital at the situation, without looking first at risk analysis and SOP solutions, assumes 100 percent risk for every possible use and is generally not smart spending. With a quantitative approach, you don’t need to plan for the worst-case consequence, only the measurable risk.”

The Designer’s Roadmap

Whether building a new facility or maintaining compliance in an existing one, the high-level objective is to pass inspection. The following steps involve all stakeholders and avoid analysis-paralysis and overspending on solutions.

- Have a plan for addressing regulatory concerns.

- Identify operational implications, and design with the end in mind.

- Use stakeholder and regulator engagement as a reality check.

Looking only at obstacles related to regulatory compliance—such as airflow reversals, containment barriers, and entry/exit protocols, and integrating SOPs—provides a strong framework for planning. Clements recommends pairing high-level performance objectives with increasingly detailed strategies and tactics using the framework above, since the regulations in the 2010 revised edition of Biosafety in Microbiological and Biomedical Labs (BMBL) guidelines often don’t define all steps required to meet compliance.

“They don’t really tell you how to get there; they just tell you what you need to achieve,” says Clements. One of the biggest challenges facing the BSL-3 lab environment relates to airflow reversals. The US regulation states: The laboratory shall be designed such that under failure conditions the airflow will not be reversed. Although the goal has always been to maintain directional airflow from clean areas to potentially contaminated areas, earlier versions of the BMBL allowed for very brief periods of positive pressure. “This is a prescriptive, very specific, standard on directional airflow containment. It tells us that we must have zero reversal. The real challenge becomes: How do we do this without just throwing money at the problem?” says Clements.

Client Case Studies

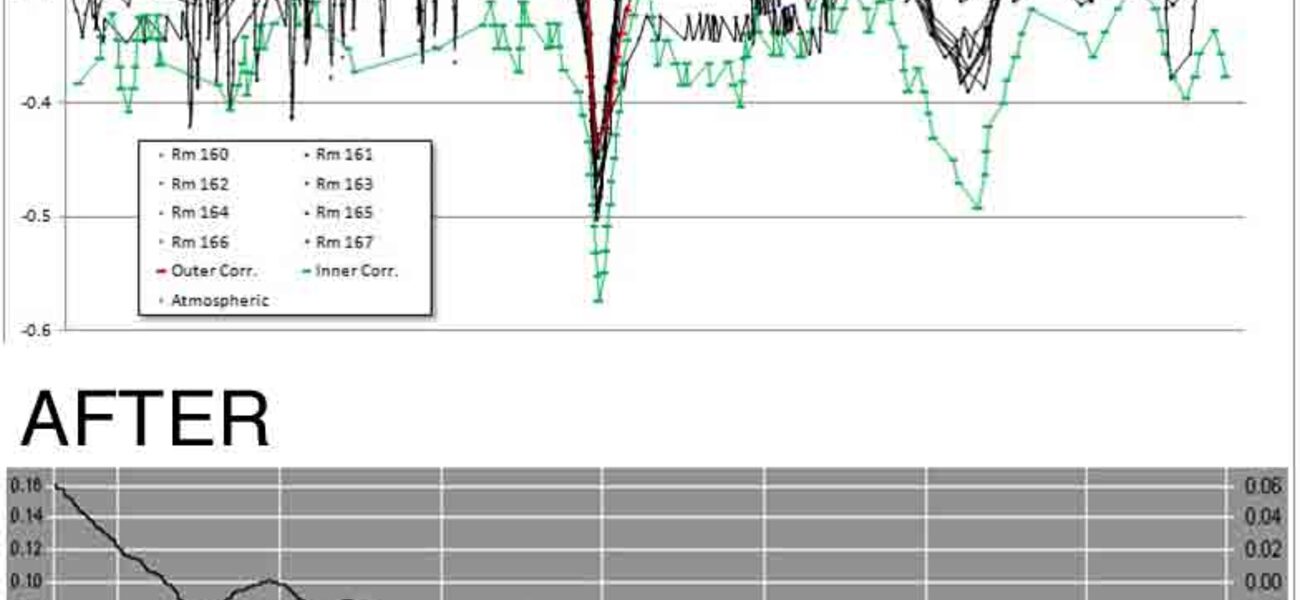

Clements describes one high-containment facility that could not be certified due to pressure inversions and air flow reversals, which the client thought were due to overly sensitive outside air sampling equipment responding erratically to changing atmospheric pressure conditions. They planned to spend $600,000 installing pneumatic air valves to solve the problem. “We decided to reframe the problem, looking only at the goal of eliminating these zone-to-zone reversals, and not assuming we were dealing with a building sensitivity issue,” says Clements. A two-day test confirmed a simpler, less expensive solution: replacing the actuators on the blade dampers for $90 each, a total cost of about $10,000. “Within 48 hours of replacing the actuators, they were getting an excellent response to atmospheric pressure change throughout the day. With about an hour of work, not counting the testing time, we were on a path toward compliance,” says Clements.

Sometimes using a quantitative risk assessment reveals the route to the best solution. USDA ARS facilities design guidelines require an airlock between zones when operating a BSL-3 (Ag) component within a BSL-3 lab block. A client whose lab had only one APR door planned a $2 million renovation, including installing double in-series APR doors between zones. Using a detailed quantitative risk assessment to determine the probability of an infectious dose of pathogen being carried beyond the holding room, Merrick looked at room parameters, localized air change rate, door movement, and personnel movement, using video to determine the air volume displaced as staff traveled through the space at varying speeds. The assessment quantified the minimal likelihood of risk.

“In our industry, we often equate consequence with risk, which is a mistake. Failing to calculate the probability of occurrence leads to overstating the risk, sometimes significantly. As we were able to demonstrate, you don’t always need the most expensive solution,” says Clements. The risk assessment model also provides quantifiable data to present to regulators during inspection.

Verifying Performance

Merrick uses a two-tiered Commissioning Verification and Validation (CVV) approach to navigate the regulatory process, providing a second tier of monitoring, assessment and evaluation, and recommendations beyond the traditional commissioning process. CVV combines two steps: verifying that the commissioning process has been completed to best practice standards for the industry, and validating the planning, design, and operations of the facility to ensure it was designed and built as planned, and fits the intended use.

“This model gets a second set of eyes on the process, independent of the contractor,” says Gilles Tremblay, director of commissioning services for Merrick. “We work through the design process with the client so the contractor knows what to achieve and to verify that all requirements are met, in order to have a seamless regulatory compliance process.” This approach may be a better fit for biocontainment projects than the traditional FDA validation model, because it allows for operational flexibility and risk-based assessment during the overall process.

The verification methodology is based on planning and documentation, including developing a traceability or compliance matrix, vendor documentation, and creating a hand-over package (HOP). “We are not looking at all the requirements for the whole project but focusing on what is critical to get the client to regulation,” says Tremblay.

The formalized risk assessment continues until all risk hazards are identified, and qualified or mitigated. The traceability matrix defines how the client plans to meet regulatory requirements, and provides the location of supporting documents for auditors.

Depending on the project, the final verification summary report lists all areas or systems identified as key components in the validation submission for licensing, such as HVAC, HEPA filtration, biosafety cabinets, effluent treatment systems, sterilizers, room decontamination, fire, life-safety, and security.

“We list everything considered critical from a regulatory perspective, and the performance criteria associated with each of these elements, from installation and operational requirements to performance and validation,” says Tremblay. For example, if reversal of airflow is a risk, the report notes the risk and includes supporting documentation on how to manage it through SOPs.

Engaging the Regulator

Tremblay recommends interacting with the regulator throughout the risk assessment process. When clients can identify potential risks, and develop a mitigating approach with supporting documentation and change management, they have fewer surprises at the end of the review. “When the regulator looks at the documentation, they will see the potential problem areas, but also how it was resolved, with the due diligence and the homework behind it, and how the users are going to manage it moving forward,” says Tremblay.

While looking at how fumigation/decontamination testing is applied is not usually part of the contractor’s deliverables, this is an important, client-driven activity at the end of the project. For instance, if the client plans to decontaminate biosafety cabinets, the risk assessment should define this methodology, including documenting how to take equipment offline if necessary. “This needs to be part of the final hand-over package. The regulators want to know how the client will operate/manage the facility safely and if the appropriate level of training is in place,” says Tremblay.

Identifying the user requirements early in the process, and documenting risk and performance requirements, results in a verification master plan with supporting documentation to satisfy the regulator. “This may seem like a time-consuming process, due to the various steps and review stages, but it’s just a more formalized, structured approach of what already happens but is just never documented properly,” says Tremblay. “When you have to do the compliance work later, the cost and time is exponential, so getting it right in the first round pays a huge dividend.”

By Mary Beth Rohde

This report is based on a presentation Tremblay and Clements made at Tradeline’s 2014 International Conference on Biocontainment Facilities.