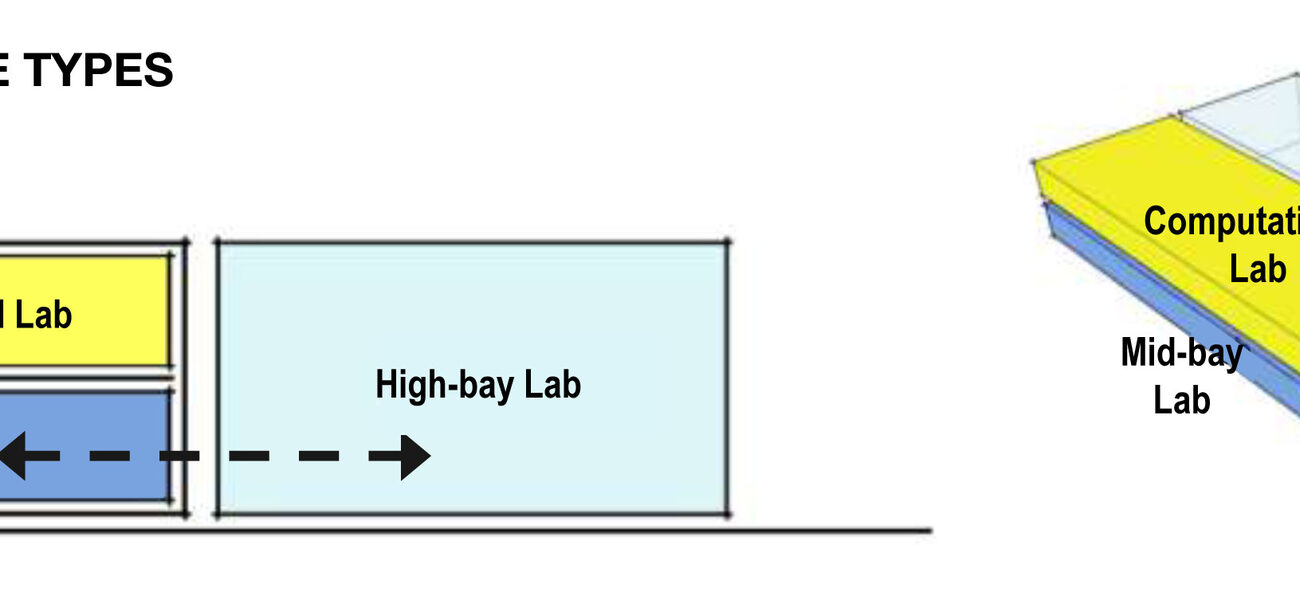

The Carbon Neutral Energy Solutions (C-NES) Laboratory at the Georgia Institute of Technology integrates three distinct types of space to create a research environment that offers optimal flexibility. The 42,000-sf building is designed to facilitate research programs of today and tomorrow by featuring not only labs and offices, but also high-bay spaces capable of housing large or heavy pieces of equipment and mid-bay spaces where the equipment is usually less than 10 feet tall.

“One of the keys to the successful integration of high bays and mid bays into a single building is maximizing the efficiency of the available real estate, creating an efficient building footprint and structural system,” says Howard Wertheimer, director of capital planning and space management at Georgia Tech. “This allows for sharing of common components, such as the loading dock, while providing cost-effective distribution of utilities and improved space allocation.”

Daniel Rew, vice president and design principal at HDR Architecture, calls the C-NES a “low-road” building as described by writer Steward Brand: It is flexible and highly functional with an infrastructure that can continually change. “High-road” buildings, on the other hand, are institutional structures that emphasize monumentality over flexibility, and “no-road” buildings refer to architecture that wins awards for fashion rather than functionality.

The rectangular building has a two-story high bay on the north side, while the south side features a mid bay on the first level and the computational labs and offices on the second level. A continuous balcony adjacent to the high bay provides an overlook to the high-bay space without disrupting its research.

“The creation of three space types allowed us to organize and segregate major elements of the program to optimally meet their individual requirements. The high bay is very flexible and used for large-scale experiments with less stringent environmental requirements,” says Rew. “The mid-bay space, while also flexible and connected to the high-bay, is more easily controlled and provides for tighter environmental parameters. The computational labs are segregated from the other laboratories.”

Successful Integration of Spaces

“Breaking the program into three types allows for maximum flexibility, especially between high- and mid-bay laboratories,” says Rew. “It also gives the team a way to evaluate each space type and challenge conventional design for each of them independently.”

If designed properly, high-bay spaces can provide the most flexible and adaptable research environments. Critical to their success are easy access and distribution of utilities, specialized services and systems; proper structural design; column locations; daylighting; appropriate ventilation; overhead cranes; utility trenches; loading dock, and truck access.

“Having the right structural grid and a column-free environment is important because of the large pieces of equipment,” says Wertheimer. “Column-free space is more flexible and adaptable for the future.”

High-bay space, with its roots in 20th-century manufacturing, often features an overhead hoist, enabling a flatbed truck to drive in and deliver new equipment or remove obsolete equipment. The high bays, which are tall, slab-on-grade spaces, allow large vehicles to easily enter and exit the building.

“Equipment can be lifted over other existing equipment without adversely impacting ongoing research,” says Wertheimer. “This is particularly useful when a piece of equipment needs to be replaced.”

The location of the loading dock and the ability to maneuver trucks in and out of the high-bay space are important to ensure the effective flow of materials. A tight site for the C-NES building made it challenging to determine the logistics for deliveries. The solution was to put the loading dock on the side of the building close to the vehicular entrance to campus so it is easy for trucks to maneuver without compromising pedestrian safety.

Natural lighting is maximized at the C-NES building. A wall of translucent panels on the north side of the high bay provides natural light into both the high- and mid-bay spaces. Artificial light is not required in the high-bay lab space during daylight hours. The 32-foot high-bay space in the C-NES building is essentially a large translucent box that allows daylight into the office and mid-bay space, providing a significant savings in lighting and energy costs.

Proper ventilation is more of a challenge. Because of its volume and openness, a high-bay space is often difficult and expensive to heat and cool efficiently, says Rew. As a result, the C-NES high-bay lab is naturally ventilated with supply louvers placed low along the wall and clerestory exhaust. Large industrial ceiling fans help ventilate the space and circulate the air in lieu of air conditioning. Radiant flooring makes it possible to keep the space warm in the winter by heating only the bottom six feet of the space.

“During winter months, the fans run at low speed to push warmer air back down into the space. Occasional forced ventilation is provided by higher velocity fans in the north-facing clerestory,” says Rew. “The forced ventilation system can be used to purge the space and provide the high bay with up to nine air changes per hour in the event of higher future space loads.”

The mid-bay space of the C-NES contains one chilled water VAV air handling unit that is fitted with dual energy recovery wheels. The unit is intended to meet ventilation requirements and provide the space with air temperatures that range between 68 and 72 degrees. Cooling for individual rooms is accomplished with individual fan coil units.

The computational lab and office area uses a displacement ventilation strategy with an under-floor air distribution system. Occupant-controlled floor diffusers are located throughout the space to maximize comfort.

The high-bay laboratory was designed with a temperature range of 68 to 80 degrees, anticipating that heavier work can adapt to that range. The mid-bay lab was designed with a 70 to 76 degree range with the ability to provide individual lab spaces with more stringent temperature and humidity controls. The computational labs and office space were designed to a temperature range of between 70 and 76 degrees, which is a non-typical adaptation of a traditional office environment.

“We think the connection of high-bay and mid-bay space in a very open, flexible environment is an interesting concept. The biggest challenge for the three space types involved identifying appropriate mechanical and utility distribution strategies without unnecessarily complicating the building,” says Rew. “The result is a building with three separate, yet integrated, mechanical solutions.”

Flexible, Accessible Utilities with Combined Space Types

The high bay at the C-NES building is well suited to accommodate research on sustainable energy solutions, including high-efficiency combustion engines, biomass gasification kinetics, biochemical enzymatic conversion of biomass materials, and the capture of carbon dioxide from power plants and combustion energy. The pressurized entrained flow reactor, also known as a gasifier, is a very large piece of scientific equipment that would not fit into a traditional research building.

The building is designed with an inherent flexibility to accommodate expanding, contracting, and evolving research programs; to minimize the need for modifications for different research programs; and to allow projects to be easily moved without the need for reconfiguration. A flexible utility system is critical.

“Having a flexible pathway system for the distribution of utilities and easy access is important,” says Wertheimer. “We want researchers to use the building in a plug-and-play manner where it is easy to understand the framework of utilities and it’s easy to get utilities where and when they want.”

The utility system features underground trenches where air distribution, power, and data come from the flooring system. Cords, hoses, and piping can be placed in the trenches around the perimeter of a space and distributed to any location in the building because there are no physical barriers preventing access to the utilities. Overhead distribution and power panels are also accessible to accommodate the researchers.

“The C-NES laboratory uses an east-west utility zone within the catwalk in the center of the lab as a utility distribution spine,” says Rew. “Utilities branch off to the north high bay in floor trenches and to the south in a horizontal utility plenum located directly above the mid-bay labs and below the computational labs and offices.”

Designing for the Long Term

Georgia Tech has a history of utilizing low-road buildings with high-bay space to meet its changing pedagogies. The Institute’s first free-standing research facility, the Hinman Building, was constructed in the early 1940s as a high-bay space with an overhead crane to facilitate research for the gyroscope, helicopter, and microwave. The Hinman Building was recently repurposed for the College of Architecture by converting some of it to studio space and exposing the tectonics to transform it into a living learning environment.

“The nice thing about properly designing a high-bay space is that it is adaptable and flexible forever, for the life of that building,” says Wertheimer. “We repurposed the building for the next 30 years and in 30 years, it could be something else because it was smartly designed 75 years ago.”

Designing flexible buildings that can meet the needs of today’s researchers and be easily reconfigured to suit the demands of tomorrow’s research requires a willingness to set ambitious goals and to be innovative. This may mean integrating several types of space into one building.

“The challenge is to keep it simple. We started out with a rectangular box and everyone wanted to explore other options,” says Wertheimer. “But every other geometric option had more challenges. We realized the rectangular geometric form is the most effective for a lab building because it provides clean lines, clean circulation, and the most connectivity from one space to another. You get the most space efficient laboratory.”

By Tracy Carbasho

This report is based on a presentation given by Rew and Wertheimer at Tradeline’s 2012 College and University Science Facilities conference.