University of Oklahoma's Stephenson Life Sciences Research Center (SLSRC) is improving research productivity and attracting millions in grant funding thanks to a focus on transparency, flexible floor plans, and strategic multidisciplinary collaboration. The new academic research facility features an extensive use of interior glass, flexible modular furniture, and shared imaging resources, including NMR and x-ray crystallography equipment. Since completion in 2010, the center has noticeably improved student/faculty interaction, researcher collaboration, public awareness, and grant funding.

The 160,000-sf, three-story facility—which was built in collaboration with PGAV Architects—houses the chemistry and biochemistry department and supports multiple investigators who share equipment with each other, as well as with researchers from other units on campus.

“We didn’t just call it a ‘chemistry’ building,” says George Richter-Addo, professor and chair of OU’s chemistry and biochemistry department. “We called it a ‘life sciences’ facility because we do chemistry related to life sciences, whether it is bone repair, antibiotic resistance, neurodegenerative disease, or natural products.”

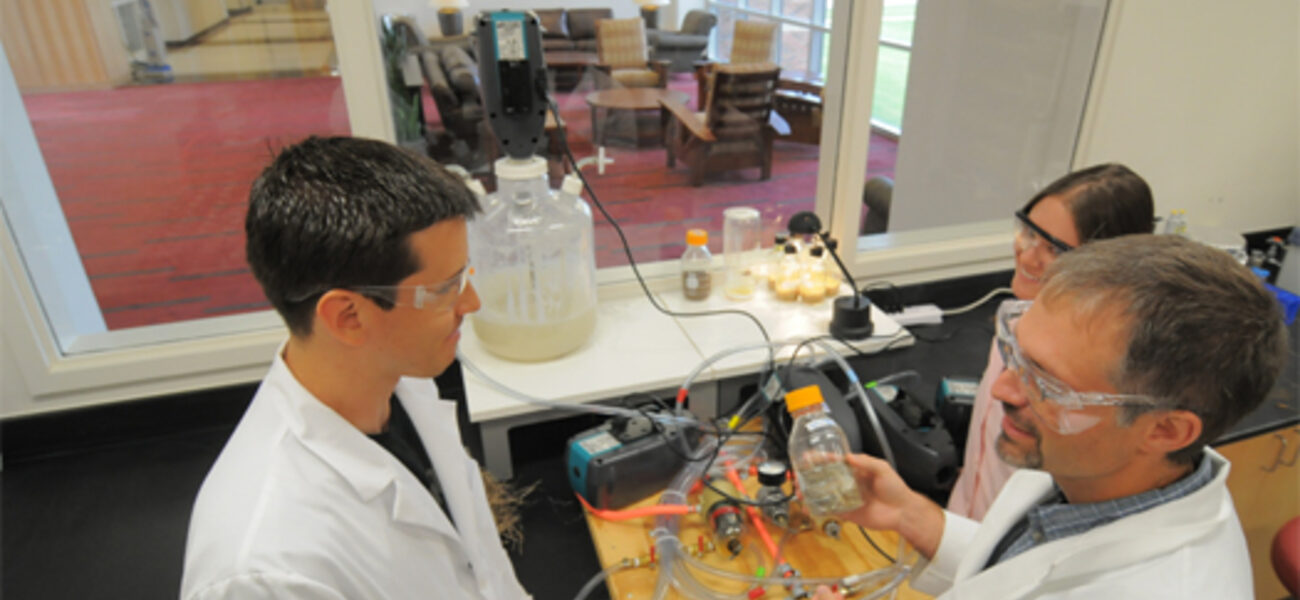

The advantage of an open lab model is that it improves synergies between researchers with common objectives, but strategic collocation is the key to successfully sharing resources, ideas, and objectives, says Robert Cichewicz, director of the newly formed Institute of Natural Products Applications and Research Technologies (INPART) that is housed in the SLSRC.

“Removing barriers enables a freer movement and a more fluid exchange of ideas that can really increase the collaborative nature of science,” says Cichewicz. “But you can’t simply build an open lab and expect collaboration to happen on its own. You have to support those initiatives by putting the right people in the right places.”

“Rather than locate investigators by the traditional subdivisions of physical chemistry, organic, or biochemistry and so on,” says Richter-Addo, “We ask the questions: ‘What concept area are you working in? Are you working in catalysis? Are you working in structure-function? Are you working in biomaterials?’ And then we collocate them accordingly.”

Sharing Resources by Design

In some multidisciplinary research facilities, much of the shared equipment may belong to a single large grant account associated with one research theme. But there can be some resistance to an open lab design by faculty members when each faculty member has his or her own grant. While Stephenson’s lab resources are shared among multiple investigators working on different grant-funded projects, there have been no significant territorial conflicts or property control issues to date.

“Initial fears that a lot of faculty voiced against the open lab concept turned out to be nonissues,” says Richter-Addo. “In two years, we’ve had zero complaints about lab items going missing. And the increased productivity and funding indicate that it’s been a real success.”

In addition to sharing lab resources across departments, the University offsets the capital costs of expensive imaging equipment by collaborating with other schools and programs across the state. The NMR suite also features a teaching area with a whiteboard and moveable tables, as well as a nearby conference room and laboratory prep area.

“It is very difficult to prepare your samples 100 miles away and then drive here to take the measurements,” says Richter-Addo. “Sometimes you want to bring in the precursors, prepare your sample, and run them right away. So we built that capacity into the units, and it is really helping regional schools come in and use the facilities.”

Such a diverse range of occupants also requires heightened attention to accessibility.

“Initially, many faculty members wanted an ADA bench in their lab,” says Richter-Addo. “In the end, we exceeded the University’s ADA requirements by a factor of five. We have ADA benches and fume hoods spread throughout the facility. And they’re not just for those who are or may be permanently disabled. I could break a leg and be in a wheelchair for six months, and I would appreciate the opportunity to be able to continue working.”

Every Faculty Office is a Small Classroom

Instead of clustering faculty offices at the ends of the building to inspire collaboration between faculty investigators, offices are spread throughout the facility, in direct response to students’ wishes, to drive better collaboration between students and their faculty mentors.

“Many of the important observations that lead to great discoveries and patentable innovations come from the students,” says Richter-Addo. “So the most important collaborations in the facility are happening between the students and faculty. We did our best to help facilitate that.”

Another feature that improves student/faculty collaboration is that every faculty office is also essentially a small classroom.

“The average size for a science office in the U.S., at the time, was around 130 sf,” says Richter-Addo. “We changed the thinking around this to instead create mini-classrooms that are 210 sf. They have a faculty desk in the back, but there’s also a student desk area, and a whiteboard. The return on investment has been that a lot more students are using office hours now.”

Flexible floor-plan modules and moveable furniture mean that a lab can be moved in a single day, instead of several weeks or months, and portable pedestal-style storage units allow students to move their desk spaces just as easily. Space can also be quickly re-adapted to meet evolving research needs.

“The flexibility of the module layout allowed us to create a cleanroom adjacent to the lab of a researcher who utilizes an adjacent mass spectrometry laboratory and is interested in technology transfer,” says Richter-Addo. “That helped the center win our first million-dollar Phase II Small Business Technology Transfer grant. So, while a facility like this can be expensive to build, the return is realized in increased grant funding.”

Science on Display

Extensive use of interior glass throughout the facility maximizes visibility between investigators and also gives the public an unprecedented view of science in action.

“We did not build a basement to put the NMRs in,” says Richter-Addo. “They are in public view because we want people to see the interaction of humans and machines for the benefit of human health. We’ve also found that when you can see from one end of a 24-module wing to the other, it creates a sense of partnership and community that we did not have before.”

In addition to a glass-lined public entry and windows in most doors and walls, the building’s second floor features a glass-walled interactive viewing lounge called the “Chemical Zoo,” which is designed to inspire public engagement with the process of discovery.

“You will not find Post-It® notes on the glass windows in the laboratories and offices,” says Richter-Addo. “Because eventually a Post-It® note becomes a postcard; the postcard becomes a small painting, which becomes a calendar, and suddenly we are closed in again. So, for physical transparency reasons tied to laboratory visibility/safety and the comfort level of students during office hours visits, we don’t permit the blocking of the glass windows.”

Same People, Better Results

The success of the open lab model at OU is evidenced by a corresponding increase in documented research, publication rates, and access to funding. Strategic collocation of investigators and resources helped the center recently attract $10 million from the Centers of Biomedical Research Excellence (CoBRE), and an additional $3 million for the natural products group.

“One of the big take-home points is the importance of keeping a focus on the students,” says Richter-Addo “We wanted to create an environment that would challenge the minds of the faculty and inspire visitors, but above all we wanted to challenge and inspire the students.”

“The thing about a facility like this is that if you’re thinking about solving big problems and moving away from a single-investigator format, it’s going to work,” says Cichewicz. “But if you’re doing it just because everyone else is, you probably aren’t going to be successful. In order for it to really work, there has to be a greater sense of purpose behind the science, where it’s not just about supporting the individual; it’s about supporting teams.”

By Johnathon Allen

This report is based on a presentation by Richter-Addo at the Tradeline College and University Science Facilities 2012 conference.