The Koch Institute for Integrative Cancer Research is a pioneering research facility that brings together biologists working to understand the disease at a molecular level and engineering faculty devoted to solving problems related to cancer. The ultimate goal is to accelerate the discovery of cures for cancer. The building accommodates 27 research groups and 460 researchers, various support spaces, 15 "core" laboratories, faculty and administrative offices, a 220-seat divisible meeting room, 14 conference rooms, a public café, and a street-level public gallery that displays video and images generated by the MIT cancer research community. The building also includes a below-grade loading facility and tunnel service connections to adjacent buildings.

Research initiatives include exploring the molecular and cellular basis of metastasis, cancer immunology, detection, and monitoring; personalized medicine; and the development of nano-scale devices and drugs for targeted delivery of cancer therapies.

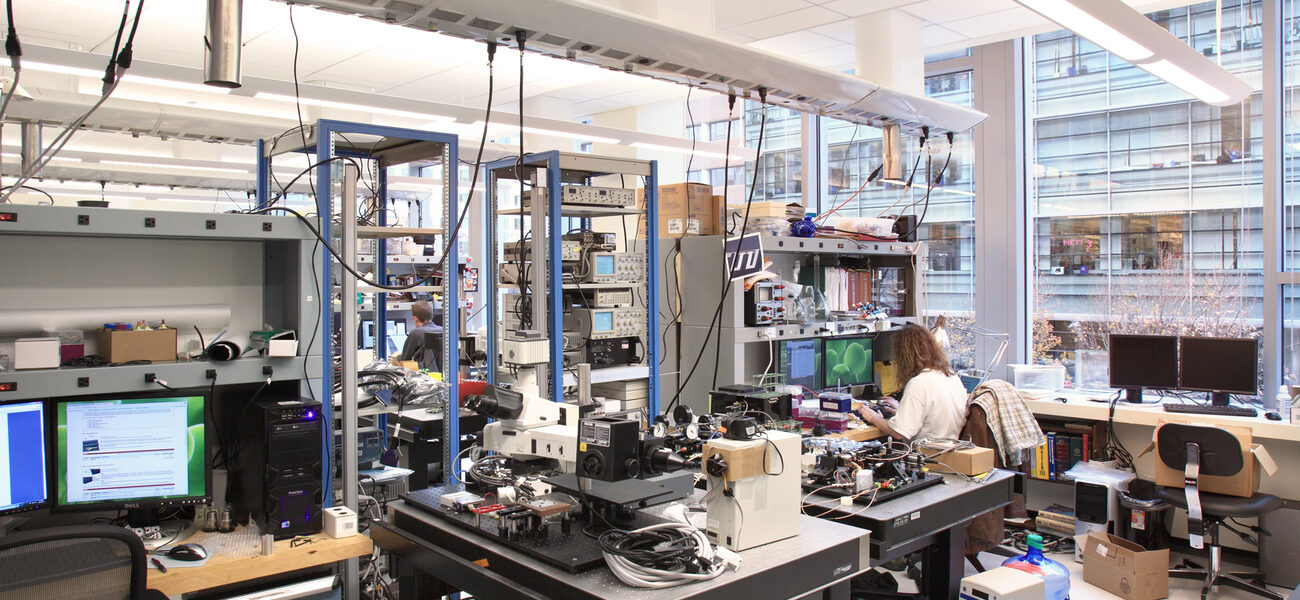

The compact laboratory floors are organized to maximize the interaction of the researchers and opportunities for shared use of both space and research equipment. The research layout features a central, shared laboratory support zone bounded by a “race track” corridor. Bench laboratories on the perimeter enjoy generous daylight. Faculty offices, open lounges, meeting rooms, tea rooms, office support, and vertical circulation are all located at the center of the research floors. This layout generates efficiencies in the researchers’ use of resources, and opportunities for the unplanned, serendipitous encounters that contribute to research advances.

Prominently located at the northern edge of the MIT campus, and at the heart of the developing biosciences district of Kendall Square, the building knits together the campus and the urban fabric of Cambridge, creating an important new campus gateway, a pedestrian-friendly streetscape, and the largest new campus courtyard since the Cambridge campus was constructed almost 100 years ago.

The LEED Gold-certified project has achieved an energy performance superior to the original energy model, which projected that energy consumption would be 35 percent better than a “baseline” laboratory building. Metering confirmed that the building instead performs 38 percent better than the baseline. This level of energy performance resulted from an integrated design process between design team and owner:

- A managed approach to lab flexibility set a future maximum of 1.5 fume hoods for each 540-sf lab module, for a maximum of 200 fume hoods in the building. (Upon completion, the building included one fume hood per lab module.)

- Electrical plug-load assumptions were based on metered data from similar facilities, resulting in reduced electrical loads compared to conventional engineering guidelines.

- Re-evaluation of conventional thermal comfort standards resulted in a setting of 72 degrees vs. 74 degrees.

- The centralized office zone facilitated the use of a cascading ventilation system and active chilled beams over a large part of the floor plans.

- MIT’s environmental health and safety group approved new energy-conserving ventilation standards:

- Fume hood design face velocity was 60 feet per minute.

- Actual fume hood operation was accepted at 60-80 feet per minute, based on ASHRAE 110 commissioning tests.

- Air-change rates in occupied spaces were reduced to 6 ACH.

- Air-change rates in unoccupied spaces were reduced to 4 ACH.

Further energy conservation measures included:

- A heat-pipe heat recovery system integrated into the air handling systems.

- Perimeter lighting controlled by a daylight dimming system, which is also integrated with the mechanical building automation system.

| Organization | Project Role |

|---|---|

|

Architect

|

|

|

Suffolk Construction Company

|

Builder

|

|

The Design Initiative, Inc.

|

Consultant - Furniture

|

|

Reed, Hilderbrand

|

Consultant - Landscape Architect

|

|

Lam Partners Inc.

|

Consultant - Lighting

|

|

LeMessurier Consultants Inc.

|

Consultant - Structural Engineer

|

|

The Green Engineer

|

Consultant - Sustainable Design

|

|

Armstrong World Industries

|

Supplier - Accoustical Ceiling Tile

|

|

TMI Climate Solutions

|

Supplier - Air Handlers

|

|

Schneider Electric

|

Supplier - Building Automation Controls

|

|

Karastan

|

Supplier - Carpet

|

|

TBJ Inc.

|

Supplier - Downdraft Tables

|

|

Otis Elevator

|

Supplier - Elevators

|

|

PPG Solarban 70XL

|

Supplier - Glazing

|

|

Lutron

|

Supplier - Lighting Controls

|

|

D-sign by Caesar

|

Supplier - Porcelain Ceramic Tile

|

|

Keystones by Daltile

|

Supplier - Porcelain Ceramic Tile

|

|

Quarra Stone LLC

|

Supplier - Stone

|

|

Kawneer

|

Supplier - Windows

|