Georgia Tech’s Carbon-Neutral Energy Solutions (C-NES) building sets a new standard for sustainable design for buildings of its type by optimizing passive energy technologies, reducing energy demand, and maximizing the use of renewable energy: A prototype living, learning laboratory that offers lessons for future net-zero attempts. Net-zero energy defies the historical reality that laboratories can consume 10 times the energy of a typical office building, and one six-foot fume hood consumes as much energy annually as a 2,500-sf home.

The C-NES building contains three types of flexible laboratory spaces: High-bay (for large-scale research), mid-bay (for lower-scale projects requiring more stringent environmental control), and computation laboratories.

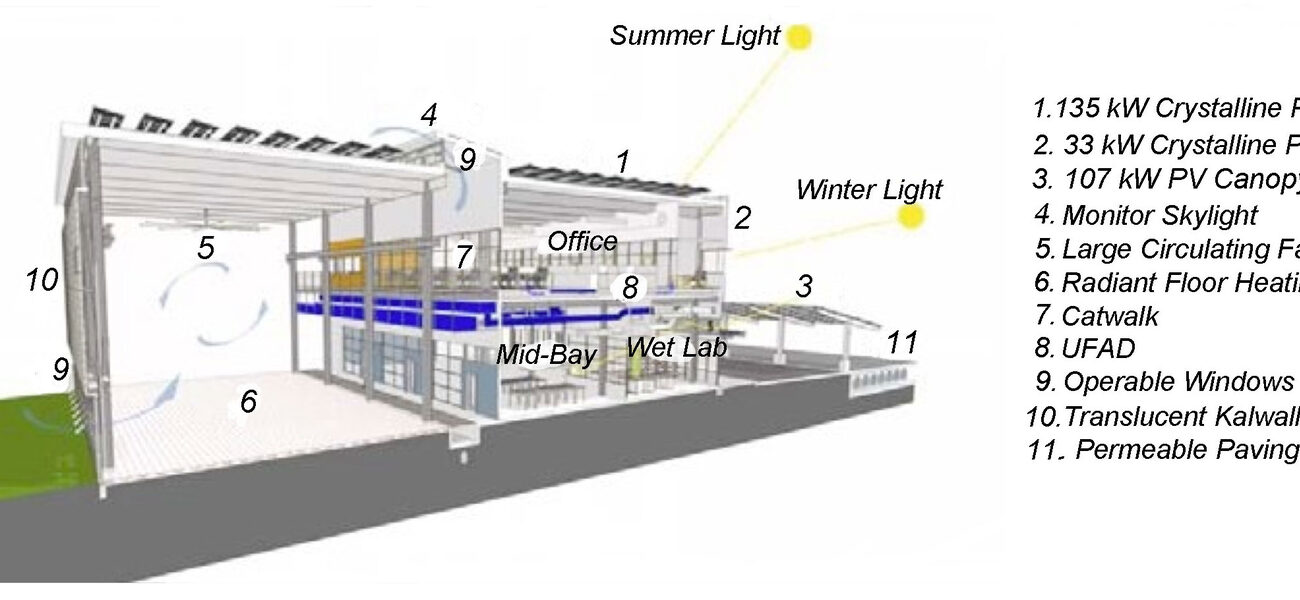

Stretched along an east-west axis, the building maximizes diffuse clerestory light in the middle of the structure on the long north façade, deeply illuminating the naturally ventilated high bay. The need for artificial light has been greatly reduced elsewhere in the building, as well, where lighting controls are multi-tiered to target lighting on an individual workspace without lighting unoccupied areas. Crystalline photovoltaic panels along the south wall, shading canopy roof, and parking area generate 296 kW of power.

The building contains 8,800 sf of office space, 7,500 sf of labs, and 8,300 sf of high-bay space. Lobby and conference areas comprise 990 sf. Offices and computational labs are stacked above the mid-bay labs, and both are adjacent to the high bay. Separation of program spaces allows for tailored temperature and humidity for each zone. The acceptable temperature range of the facility has been expanded to conserve energy used for heating and cooling, with greater air circulation and venting to maintain comfort. Radiant floor heat is used in the high bay.

Other energy components in the LEED-Platinum facility include PV panels, louvered windows for natural ventilation, energy recovery, solar desiccant recharge, displacement ventilation, and localized exhaust in small heat-intensive areas. The building also employs under-floor air distribution in office areas and dual-enthalpy wheel heat recovery AHUs. A 20,000-gallon cistern collects rainwater for toilet flushing and HVAC processes. No potable water is used for flushing or site irrigation, and low-flow fixtures and waterless urinals further reduce water consumption.