As demand for lab space continues to grow, research universities have been looking to upgrade their aging on-campus buildings to support state-of-the-art research. But doing so means they have to decommission valuable square footage, often for multiple years. For urban universities with little room to spread out, this is a particular challenge. As a result, more universities are exploring their off-campus options, in particular the opportunity to take advantage of adjacent office buildings sitting vacant since the onset of the pandemic. Just as some life science laboratories are renovating available space in urban high-rise buildings, universities are likewise looking at similar sites for their potential as decant and expansion space to facilitate on-campus renovation.

“Cities are crying out for new tenants, and research needs continue to grow,” says Jay Deshmukh, associate principal at Arcadis (formerly IBI Group) and practice lead for education projects. “When you have a campus that’s landlocked, it’s a win-win. There’s a lot of empty office space—it’s as simple as that.”

Of course, converting conventional urban office space to meet the needs of modern biosafety research is not so simple. There are some thorny technical obstacles to repurposing available high-rise space for use as wet labs.

That was the challenge facing the team at Arcadis, hired to redesign high-rise commercial office space into Biosafety Level 2/Containment Level 2 (BSL-2/CL2) labs for the University of Toronto’s Temerty Faculty of Medicine. The design had to offer spaces for wet benches, dry labs, offices, and training. Using interdisciplinary collaboration and an iterative design approach, however, the team zeroed in on a novel ventilation approach, as well as an adaptable design capable of meeting the university’s changing needs. The end result is an innovative, cost-effective solution that can flex to meet a variety of lab and support space requirements.

A High-Rise with Potential

The Temerty Faculty of Medicine is located in downtown Toronto, the fourth-largest city in North America. Ranked in the top 10 in the world for clinical, preclinical, and health programs, it supports more than 130 basic science wet lab principal investigators across three on-campus and two leased, purpose-built facilities. For the last decade, the medical school has been working to vacate its aging buildings, some of which are 150 years old. “They really no longer suit contemporary wet research,” says Heather Taylor, Temerty Medicine’s executive director for major projects and facilities management.

With no greenfield options at the landlocked campus, Taylor and her team turned their attention to nearby commercial office towers, whose building owners were increasingly willing to consider renting their unleased office space for lab research. Taylor had four requirements: a freight elevator big enough to transport research equipment, adequate clearance from floor to underside slab to accommodate mechanical equipment, access to roof space for ventilation, and proximity to campus. Only one building—777 Bay Street—fit the bill. It also happened to have enough space available on one floor—a fairly typical 20,000-sf floor plate—to support six BSL-2/CL2 principal investigators with an average team size of eight. A second floor was available to develop for administration and teaching purposes.

Questioning Assumptions Yields Innovative Answers

Jonathan Steel, global director of Arcadis’ Education Practice, was concerned about meeting infrastructure upgrade requirements within the building’s 12-foot floor-to-floor design. But he knew that if the team could tackle the technical challenges the project presented, they might emerge with a reusable solution that could benefit not only universities and commercial office building owners, but downtown city centers as well.

The design team’s early feasibility studies assumed that they would need to incorporate a method for exhausting fume hood gases via the roof of the office building. Since the research space was being planned for the 10th floor of a 30-floor building, it could require 20 floors of duct, typically involving the repurposing of an elevator core or core building shaft space, which would have cascading impacts on services for other building tenants. “It was costly and complex to construct,” explains Deshmukh.

However, the chemical usage required to develop credible research results had already been declining for the type of research the labs would be supporting—a byproduct of advances in measuring devices—so there was an opportunity to push back on assumptions about what substances lab users would require.

The design team recognized that a realistic calculation of what chemical usage the facility would need to support could open up the possibilities for how the designers might exhaust resulting fumes. The potential cost-effective solution was filtered ductless fume hoods. The reagent in the filter enables it to capture the fumes passing through it, setting off an alarm when it reaches capacity.

Not knowing which specific research teams might use the space, the facilities team polled a representative subset of researchers about the types and volumes of substances they typically use. The Arcadis lead consultant team reviewed the resulting list of 300 chemicals with filtered fume hood manufacturers and found just three that were not exhaustible. (Standard operating procedures were created to cover those exceptions.) This became the basis for calculations about the actual ventilation requirements. At this stage, the team took a page out of electrical system design: Just as the whole load of a building’s electrical wiring installation won’t be in use at the same time, neither would the research teams be using all the substances on the list at maximum levels at once.

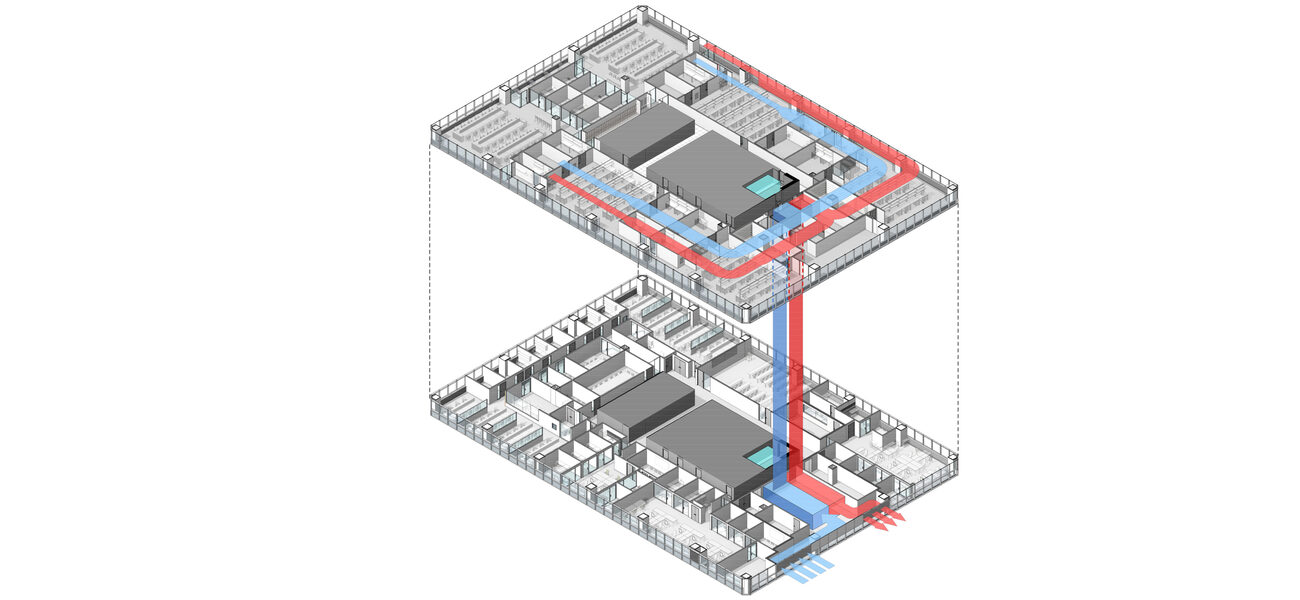

Further, the design team combined the filtered fume hoods with a back-up thimble exhaust system capable of drawing more than 100 percent of the air that is expelled by the fume hoods and venting it out of the building horizontally. While not technically necessary, “it allowed a sense of comfort for the university and building owner because they had never had labs in the building,” says Deshmukh. “People worry when there is a change from what’s typical.”

In a commercial office building, there typically will be requirements for six air changes an hour (ACH) with 20 percent of that being outdoor air. For a CL2 lab, the requirements are more stringent: 6-12 ACH using 100 percent outside air. “It’s the 100 percent piece that really pushes you above feasibility,” says Steel. “The way that we make that work in a responsible and sustainable way is to have air sampling in each of the individual rooms in the wet lab spaces. The mechanical system is programmed to ramp up and down according to a schedule, but sensors override that schedule.”

A Modular Plug-and-Play Solution

When designing purpose-built on-campus research spaces, architects are often beholden to the very specific requirements of a certain high-profile investigator. “Because we were building this off campus without individual occupants identified, we had to be more open and more experimental in our approach,” says Deshmukh. Specifically, they developed a more modular and adaptable solution.

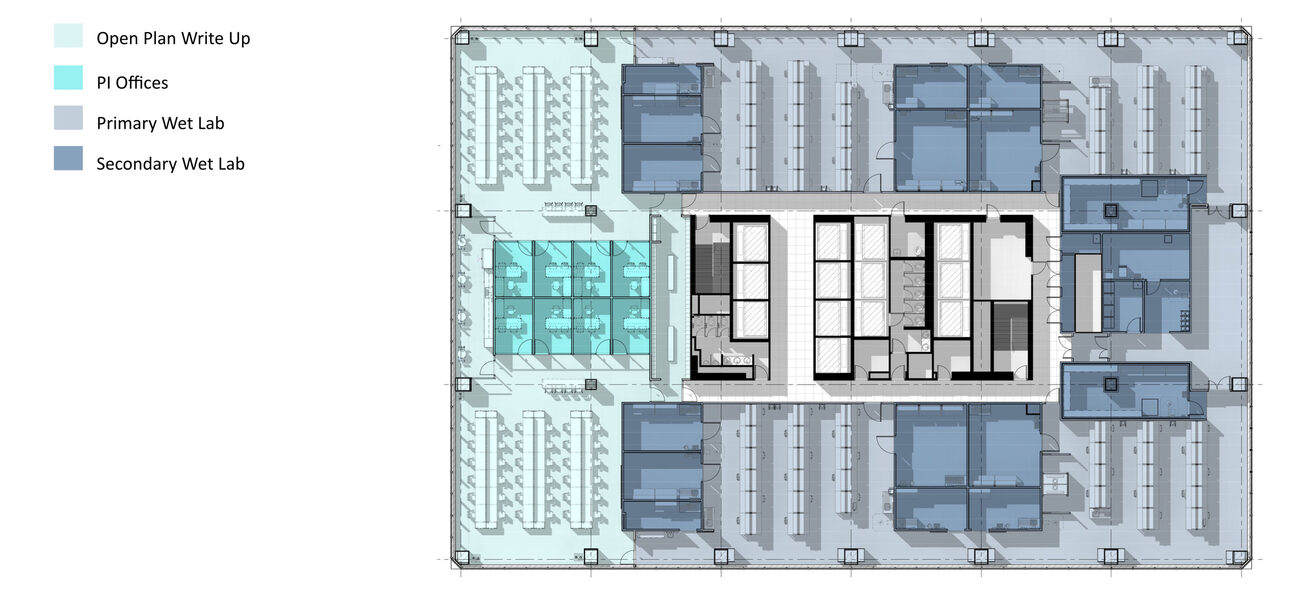

The resulting design for the Temerty Faculty of Medicine devotes about a third of the space to wet benches (14,000 sf), another nearly one third to dry labs (12,000 sf), and around a third to office, training, and infrastructure (12,000 sf, including some HVAC systems that would otherwise be on a roof). But within each footprint, there is significant flexibility.

The university was signing a 10-year lease at 777 Bay Street, and any number of different teams might make use of the space over that time. “What we developed was a very flexible solution that allows research leaders and groups to change,” says Deshmukh. “It gives U of T a lot of flexibility.”

The secondary lab space, for example, can be configured into small, medium, or large sizes, depending on the types of equipment that future research teams might need. In addition, because they designed a continuous circulation loop around the space, there is the option to give one group more space than another.

And because the design no longer demands roof space and ventilation, the two-floor module could be reused anywhere up or down the tower, or in another similar high-rise. “By releasing ourselves from some very important constraints in terms of both cost and constructability, we were also able to come up with a design solution that can be applied more widely,” says Deshmukh, “even in situations where you’re not looking at a landlocked, highly urban environment like the University of Toronto.” Deshmukh credits the close collaboration with mechanical engineers, the university, and the base building operators for coming up with the innovative solution.

Commissioning is scheduled for August, and research teams will begin relocating in the fall. “If we’re able to demonstrate success here, more people may consider these more flexible, modular designs for labs,” says Steel. “There is potential for a triple win: landlords, universities, and urban environments.”

By Stephanie Overby