As scientific research increasingly moves toward a greater use of data, so too is the animal cage technology being introduced and developed by major manufacturers. Innovations designed to improve animal life, reduce costs, and enhance research are happening at the cage level, with technology allowing for control of conditions within individual housing units and data collection of cage-level variables.

“The proliferation of big data science is starting to reach the cage level,” says Jeffrey Zynda, academic science practice leader and principal at Perkins+Will architectural firm. “The industry is looking at various permutations of how to capture data at cage level and utilize it for scientific and husbandry purposes.

“We’re starting to see a different take on the role of the cage, from being thought of as merely a holding vessel to now being looked at as the primary source of data.”

There is also increasing collaboration between manufacturers and researchers. In a competitive market, it’s not enough to sell a new widget; meeting with clients to develop custom solutions is becoming more common, note Stephen Durkee, West Coast account manager for Alternative Design Manufacturing & Supply, and Brian Bilecki, director of vivarium design services for Allentown Inc.

Allentown Inc. partnered with Charles River Labs to develop the Sentinel™ EAD® (Exhaust Air Dust) monitoring system, a recent innovation that reduces or eliminates the need for sentinel animals and overcomes the known limitations of soiled-bedding sentinels, according to the Charles River website.

“Our partnership with Charles River is the culmination of many years spent focusing on both improving the accuracy of research tools, and at the same time making real strides toward 3Rs compliance,” says John M. Coiro, president of Allentown. “It’s also an extension of the kind of support technology we’ve been bringing to market recently – solutions like Wi-Com Sensus and WiVarium Plus.”

Allentown now has a doctor of veterinary medicine on staff and is taking a more holistic view of the industry, adds Bilecki. “We can’t do a good job providing the equipment if we don’t understand the science. Sentinel EAD was a big project for us, and for us to partner with Charles River Labs to provide the best possible new technology was a really neat collaboration.”

Durkee notes that as a smaller company, Alternative Design Manufacturing & Supply does a lot of custom work for people, and that’s how a lot of their new products get designed. “Ultimately, we see a lot of items that are designed to create efficiency for people’s work process,” he says.

Home Cage Monitoring

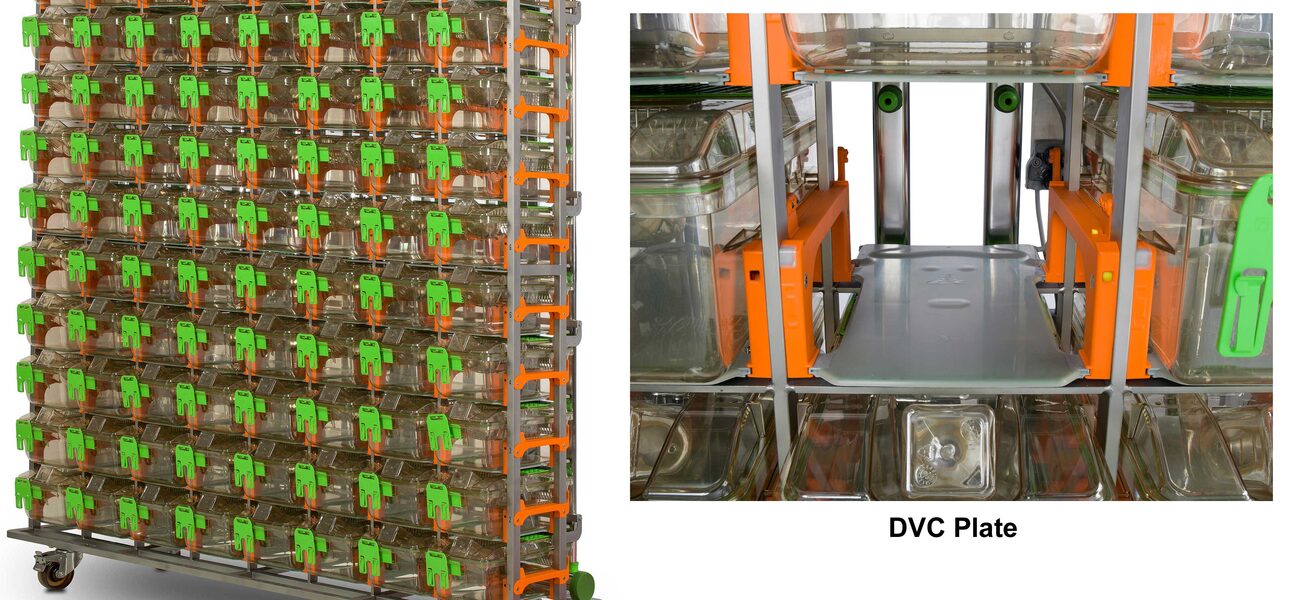

Two years ago, Tecniplast introduced a new mouse monitoring system known as a digital ventilated cage (DVC), which is currently being used by some renowned research facilities in Europe and the United States. The DVC system comprises proprietary software and hardware that captures and records data on intra-cage conditions, events, and animal activity without disturbing or affecting the animals via seven modules:

- Food and water levels

- Bedding conditions

- Animal activity

- Leak detection

- Facility planner

- Cage identification

- Cage census and location

The non-invasive washable and autoclavable system utilizes external sensors that monitor the intra-cage activity and conditions, said Richard Cluck, Tecniplast IVC product specialist for the United States. “It does this 24/7 and helps achieve desired optimal conditions, reduce cage changes, monitor the feed and water, etc.”

“Our goal was to bring standardization and improvement to animal welfare and provide facility managers with valuable information that would help increase operational efficiency and improve the management of the vivarium,” explains Marco Carrara, president and CEO of Tecniplast USA.

“Since this technology is not invasive and doesn’t affect the animals, the researchers have the advantage to obtain better data 24/7 and, therefore, improve research,” he adds.

While some of the DVC modules are strictly designed to detect changes for operational purposes (e.g. presence/absence of food and water), other modules are customized to match the facilities’ standards. For example, the judgment of what “dirty bedding” is can vary depending on the person conducting the research. To sort this variable, the DVC system goes on a six-week “learning” phase, explains Carrara, during which the customer is instructed to proceed as they normally would in changing dirty bedding. During this time, the system identifies what constitutes “dirty bedding” for that particular facility, after which the DVC is reprogrammed to match the facility standards.

From the IT standpoint, DVC is flexible and can be integrated with almost any animal management solution software. An onsite or a cloud-based server will store the data collected by the system. “The customer can utilize his own IT or cloud services to be merged with our system,” says Carrara.

The development of the DVC started approximately seven years ago and the technology has been beta tested at several sites in the United States. According to Tecniplast, during this phase, the facilities observed a 35 to 40 percent reduction in operating cost.

Solace Zone

Room temperature variations can have a significant impact on an animal’s micro environment and the reliability of research results, notes Durkee, which is why Alternative Design Manufacturing & Supply’s patent-pending Solace Zone creates a thermal neutral zone (TNZ) inside individual cages to alleviate cold stress in rodents.

The technology is especially useful for bone density studies and certain cancer studies, where temperature affects tumor growth rate, says Durkee. The ideal TNZ for mice is 85-90 degrees F, and most rodents are housed in environments almost 20 degrees lower—temperatures more comfortable for technicians.

“The Solace Zone balances that—the macro temperature in the facility can be appropriate for technicians and the micro temperature at the cage level can be appropriate for the animals that are housed there.”

A heating pad underneath each cage can adjust the temperature in 3- to 5-degree increments. The rack features include 45, 60, or 80 air changes per hour to cages, and the flexibility for use in permanent or temporary housing. A mobile unit can be unplugged and moved from place to place, with two battery backups that will provide air changes for at least 24 hours.

Other Innovations

Animal Care Systems, Inc. has introduced CageTalkers®, a unique take on inventory control systems that have been used in the retail industry for decades, says Rich VanDewater, director of sales for the company. Animal Care Systems’ technology uses an infrared system (as opposed to radio frequency used in most other census applications) to automatically take a cage census throughout a facility, even as cages are moved around. This unique application allows each cage to be located, counted, and identified, thereby providing an accurate census of cages without the need to enter every room to scan individual barcodes.

A base station controls up to 32 rooms by an ethernet cable hung in a lab. This electronic cage card system eliminates the need for paper cage cards and printers. The information that a facility’s existing animal management software sends to a physical printer is now sent to CageTalkers®. This e-card is half the size of a paper cage card and up to three full screens of data can be electronically inputted and archived, explains VanDewater.

The microbiome research world is on the cusp of exploding, says Allentown’s Bilecki, and Allentown is redeveloping its fully sealed biocontainment system from a negative pressure environment to a positive pressure system. These research animals can then be isolated and kept completely germ-free (not even populated with the normal microbiota found on/in a rodent) and ready to take part in the experimental phase of the research. This fully sealed cage system has unidirectional airflow, insuring all areas of the rack and caging are always under positive pressure, protecting the animals from outside contamination. It also utilizes redundant systems including motors, battery backup, and the first-to-market, certified, in-cage HEPA cartridge.

Allentown has created racks with 48 micro isolators, a significant innovation over currently used individual isolators that take up more room and require three to five weeks’ setup time, notes Bilecki.

“Our product allows them to do tenfold the research, because they can have two or three cages with each study group on one rack, and 10 groups on one rack as opposed to 10 individual isolators. The outcomes they are looking for are truly groundbreaking, next generation treatments and curative agents, so for us to be a part of that is exciting.”

Continuing and Future Trends

Allentown’s Sentinel™ EAD® system is headed into its second year of use, and the field of environmental air testing continues to grow, say Cheryl Perkins, scientist II, molecular diagnostics laboratory services, and Kenneth S. Henderson, Ph.D., senior director, laboratory services, both of Charles River Laboratories. Only eight presentations at the American Association for Laboratory Animal Science (AALAS) national conference dealt with the subject two years ago; the number rose to about 20 in 2016, says Perkins.

Sentinel helps facilities monitor colony health by collecting exhaust air duct particulate at the top of the vertical exhaust plenum. The collection media can then be evaluated for a custom list of pathogens by real-time polymerase chain reaction (PCR) at Charles River.

“This is going to change how diagnostics are done in this industry,” predicts Allentown’s Bilecki. “It's a better technology, you’re saving animal lives, you’re saving money, its better for technicians—this technology ticks all those boxes.”

Zynda, of Perkins+Will, says the shifting focus on environmental stability at the macro environment to the cage and rack level reduces the loads on exhaust and supply air systems as well, which can improve redundancy and overall energy efficiency in animal research facilities. “I think the industry has thankfully put a real eye on sustainability when it comes to providing products.”

Zynda also believes that while the primary focus of these innovations to date has been on rodent cages, the focus will quickly advance into other populations like aquatics.

“We’ve already seen that shift over the years in aquatics—the shift from macro system to micro system. I would imagine you’re going to start to see that type of technology applied much more widely.”

Aquatics are also becoming a greater portion of the research population. Ten years ago they represented maybe 2 percent of new or renovated facilities, and now are more than 25 percent in many cases, says Zynda. With that shift comes different housing technology, and a focus on temperature and humidity settings and water quality.

From an overall design perspective, the paradigm shift from macro to micro environment should translate into a marked decrease in facilities costs and a slight increase in equipment costs, adds Zynda.

“The real game changer here is what if we can push cage changes to 30, 60, 90 days or more without affecting animal health or scientific output? Now all the rules and metrics compiled over the past 30 years are kind of thrown out the window.”

By Taitia Shelow