A hands-on, interactive, and problem-oriented approach to learning is taking campus planning and design by storm, focused on equipping students with the skills they need to tackle near-term and future challenges globally. Increasingly, universities are recognizing students’ desire to connect their educational experience with real-world applications, and “maker spaces” provide that intersection. They also appeal to big industry and help to connect students with job opportunities, particularly in STEM fields. All of this adds up to a wave of change that architects, planners, and engineers should be prepared to catch.

Although they trace their origins to DIY and hacker cultures, maker spaces in schools may be loosely defined as on-campus locations where tools, resources, and knowledge are available to be shared. They differ from traditional learning environments in that students drive every effort; they may be assigned a challenge or task, but are largely responsible for identifying problems themselves and working together to solve them. Experts—including professors and graduates familiar with the sophisticated equipment that is made available in a typical maker space—are there for training and to answer questions.

This shift in pedagogy has required a reciprocal shift in planning, designing, and implementing the next generation of learning facilities. “Maker spaces are gaining huge traction,” says Terry Brown, senior project manager with San Diego-based Research Facilities Design (RFD). “In the past four or five years, we have done two or three a year.” Some projects reimagine underutilized facilities as maker spaces, increasing value without sacrificing existing space; others are wholly or partly new construction.

While some students and student groups use maker spaces primarily for discussion and ideation, advanced manufacturing training is without question the use with which maker spaces are becoming synonymous. “The idea of maker space is really about product realization,” says architect Sean Towne, also of RFD. “It’s about teaching the process from design to implementation to product.” A primary impetus for universities is connecting students with the workplaces that will eventually make their investment in their education pay off.

The Top Four Issues

According to Jim Shackelford, senior project manager in the University of Texas (UT) System’s Office of Facility Planning and Construction, four core findings drive the planning and design of a successful maker space. Firstly, the need for such spaces is student-driven. “Young people need physical spaces to collaborate, network, and test ideas,” he says.

The second core finding builds on the first: In a maker space, students ideally are also building social capital—exchanging ideas and learning from one another. “Innovation becomes a social enterprise,” says Shackelford. “Students are making connections that are vital to their success.”

Third, traditional pedagogies have not historically equipped all students with direct career paths, or with the hands-on skills and problem-solving attitudes they need to appeal to employers in their chosen fields. In addition, the exponential evolution of technology requires a degree of agility and curiosity that many industries might not have previously valued as highly has they do today. “A lot of schools are not built to prepare students for today’s economy,” says Shackelford. Many of the larger maker spaces that RFD designs use the same infrastructure and are working models of what engineering students will encounter in the real world. “They need real-world infrastructure in order for product creation to take place,” says Brown. “The equipment and knowledge they’re accessing could be for Boeing, or Chrysler.”

Lastly, those fresh from college or graduate school face issues of equity in entering the workforce. The Millennial generation is still facing a tough economy, and in many if not all industries, experience still trumps youth. “We want to make sure that the students who are graduating from our institutions of higher learning are prepared to compete for jobs in the marketplace,” says Shackelford. This means providing opportunities to gain vital experience before graduation.

Building and Equipping an Effective Maker Space

Access and ease of use are non-negotiables for any maker space. The UT Cockrell School of Engineering found that its engineering students were arriving without hands-on experience with some basics, including welding. Its Longhorn Maker Studio, now housed in the Mechanical Engineering Department, offers training for all of the space’s machines and software. Longhorn now includes not only 3D printing (fairly standard for university maker spaces in 2016) but also laser and plasma cutters, mixed signal oscilloscopes, and advanced software, such as myRIO and AutoCAD variants. “A student can drop by the studio during regular operating hours and receive training on any of the machines,” says Shackelford. “And the lab is open a lot of hours—14 hours Monday through Friday, and then 12-7 p.m. on weekends.”

Duke University’s maker space, The Foundry, provides similarly flexible hours, and has found that this openness tends to foster more extracurricular use. “Prior to its renovation, Gross Hall (where The Foundry is located) housed eight different groups or centers, making it a prime candidate for a highly flexible maker space, says Rebecca McDuffie, a senior associate with Foundry designers Lord Aeck Sargent. “Additionally, being centrally located on campus afforded the ability to bring in even more groups, including the School of Engineering and Physics, which further enriched the possibilities for cross-disciplinary learning and discovery.”

Flexible access enables students to complete projects in shorter timeframes, as well. “All the tools they need are in a single location,” Shackelford points out. Since its opening in 2014, the Longhorn facility has been used by over 2,500 students in eight of the courses offered. These include aerospace, biomedical, architectural, chemical, electrical/computer, mechanical, petroleum, and materials science engineering.

Connections with Private Industry and Research

Private industry is increasingly taking an interest in contributing to these environments and the tools that drive them. At UT’s Cockrell School, approximately 60 percent of the equipment for the Longhorn Maker Studio was donated by private industries specializing in microconductors, computers, and electronics. At other institutions, including the University of Virginia (UVA), formal or informal partnerships are being explored. UVA is part of a consortium—the Commonwealth Center for Advanced Manufacturing (CCAM) —which includes the Commonwealth of Virginia, Virginia Tech, Rolls-Royce, and NASA, among more than 20 other institutions and private companies. CCAM is explicitly devoted to connecting the research taking place on campus with manufacturers that have commercial challenges to solve. “Universities are really good at coming up with solutions looking for problems,” says Barry Johnson, a UVA senior associate dean.

The types and scales of projects students tackle in maker spaces vary widely. They may be as complex as a super-high-efficiency vehicle or as elegantly simple as a custom mobile phone holder. All components, from circuit boards to chassis, can typically be designed, prototyped, and refined using instruments and materials found in the maker space itself. One team at Duke has created a tick-gathering robot, aimed at furthering Lyme disease research. Another is focused on human-centered design improvements to the built environment, addressing issues from accessibility to ergonomics.

At UT’s Cockrell School, one project with far-reaching implications has been an award-winning, low-cost patient monitor. FreePulse, the brainchild of UT student Reece Stevens, provides basic monitoring for heart rate, pulse oxygen rate, and electrocardiogram signals.

During travel in Rwanda, Stevens had been appalled that a hospital he visited was equipped with only five patient monitors for its 400 beds. Recognizing that the economic threshold of $1,000 to $10,000 per unit was the primary challenge, he went about designing and eventually producing a low-cost patient monitor; FreePulse units come in at only $200. “Every component, which includes circuitry, touch screen, and a rugged case, was created in the Cockrell School’s maker space,” says Shackelford.

FreePulse was awarded first place by the global organization Engineering World Health, as well as third place in the National Institutes of Health’s Design by Biomedical Undergraduate Teams (DEBUT) contest. More importantly, it is already in the hands of Rwandan doctors. Leveraging the tools made available to him in a maker space, Reece Stevens has made a lasting impact on world health.

The Way of the Future?

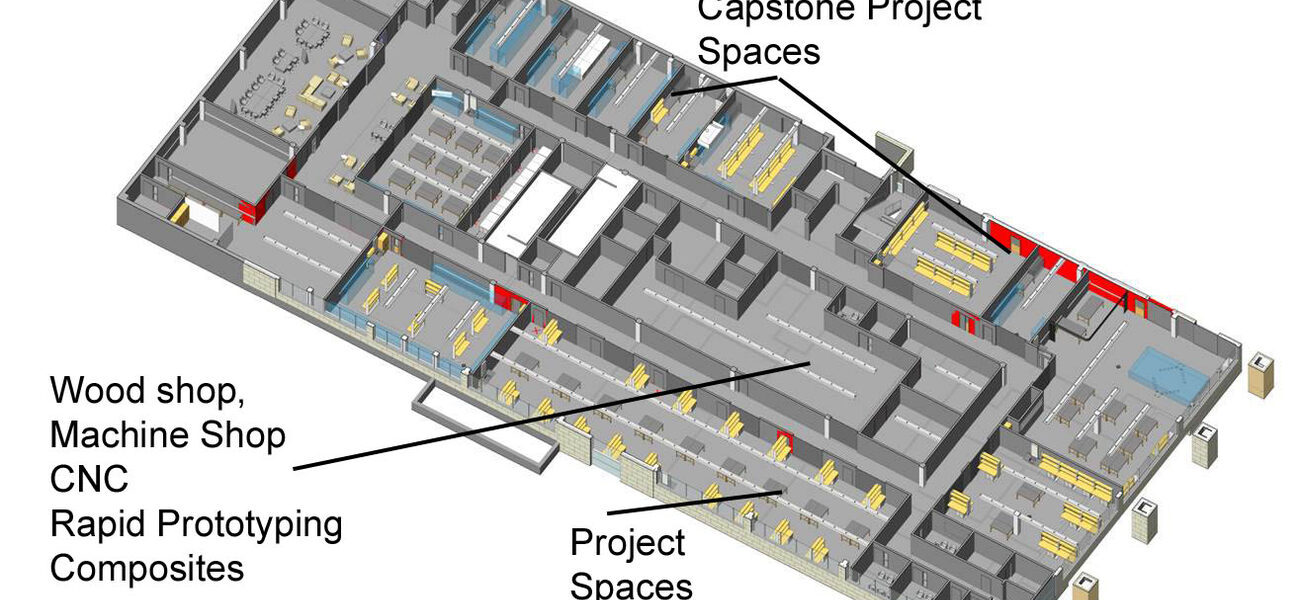

Maker spaces are not going away any time soon. Even at institutions without dedicated maker spaces, the trend is toward less structured learning, and informal breakout spaces where students can interact and collaborate. Brown counsels fellow architects and planners to understand what is driving the desire for a maker space on a particular campus, and to investigate innovative and cost-effective ways to establish them. “Is it a donor of a building who wants a maker space? Is it a renovation? Is there a need for a new building replacing something else, and here is an opportunity?” At Brigham Young University, RFD helped design a new engineering building that includes an all-encompassing, 21,000-sf maker space that occupies the entire floor plate and includes the four common components of maker spaces: design ideation, shop and manufacturing, project assembly/storage and testing spaces. “Other schools may tend to develop a loosely affiliated, fairly independent ‘necklace’ of user spaces,” says Brown. “It depends on the need, the budget, and the opportunities presented by a strategic plan.”

Maker spaces and the pedagogy they support provide the opportunity and the incentive for students, faculty, and private industry to unite in applying fun, edifying, and real-world problem-solving to the far-reaching benefit of all. “Make a financial commitment to making the maker space successful and usable by the students,” says Shackelford. “And don’t forget to make it fun. I suspect that the kids who created the FreePulse device had a lot of fun in designing, building, and testing it. They learned a great deal, and they helped a struggling 400-bed hospital half a world away.”

By Liz Batchelder