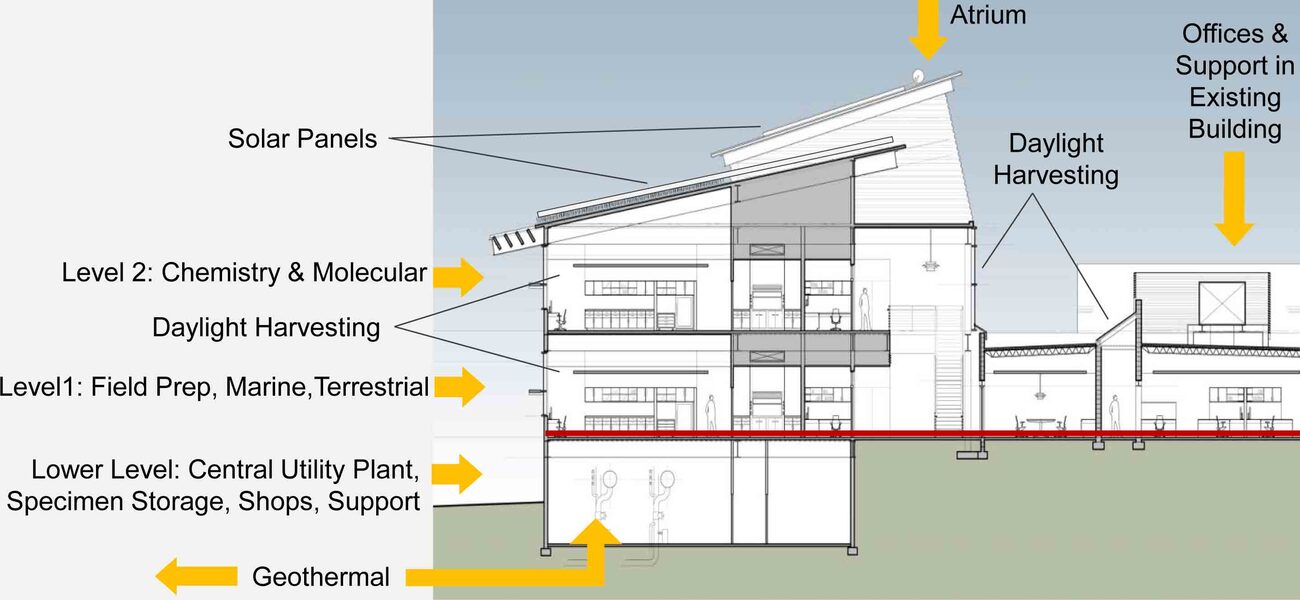

A three-story, 69,000-sf addition and 21,000-sf renovation to the Mathias Laboratory at the Smithsonian Environmental Research Center greatly enhance the Institution’s capacity for environmental research in Chesapeake Bay. A two-story atrium connects the old and new sections and creates collaboration space for more than 180 researchers, technicians, and students investigating global climate change, the effects of nutrients/chemicals on the environment, fisheries, biological threats, and wetlands/woodlands protection.

Renovations to the existing building include the relocation of many of the labs and the creation of much-needed offices; training, conference, meeting, and storage spaces; and loading docks. The addition was built into a slope to maintain a lower profile in keeping with the adjacent structures.

The facility was designed to cluster researchers in “guilds” that share research and equipment: trace element chemistry, environmental chemistry, molecular ecology, marine studies, estuarine ecology, and terrestrial ecology. The labs are organized by single and double 11-by-44-foot modules, separated by a full-height wall. Service carriers are overhead, with fixed benches along the perimeter and moveable ones in the center aisle. Exhaust snorkels are also moveable. Fume hoods are segregated in equipment rooms.

The facility was the first Smithsonian property to earn LEED Platinum certification. Sustainable features include:

- High-efficiency enthalpy wheels that recover energy from exchanged air

- Demand-control ventilation of lab spaces

- An HVAC system supplied by 300 geothermal wells 350 feet deep

- 1,015 solar panels, which generate 352 kilowatts of electricity

- Low-flow fume hoods

- Storm-water management with cisterns and wetlands made up of a series of cascading pools lined with native plants to receive runoff

- Solar panel recharging stations for electric vehicles

In addition, all of the water used in the building, as well as rainwater collected from the roof, is filtered through a wastewater treatment plant on campus, then reused for fire protection, irrigation, and bathrooms. The result is 100 percent reclaimed water and 60 percent reuse of domestic water. Utility savings are $384,000 annually, with an annual reduction in carbon emissions of 2,600 tons.

| Organization | Project Role |

|---|---|

|

EwingCole

|

Architect

|

|

Hensel Phelps

|

Construction Manager

|

|

EwingCole

|

Interior Designer, MEP Engineer

|

|

Woods Peacock Engineering Consultants

|

Structural Engineer

|

|

Alpha Corp.

|

Civil Engineer

|

|

Environmental Design Consultant

|

|

|

LaSalle Engineering

|

Fire Protection/Life Safety Engineer

|

|

GeoConcepts Engineering

|

Geotechnical Engineer

|

|

J and P Engineers

|

Geothermal Engineer

|

|

Froehling & Robertson

|

Environmental/Hazmat Consultant

|

|

Poole Design

|

Landscape Architect

|

|

Cornerstone Commissioning Inc.

|

Commissioning

|

|

Goodwin Brothers

|

Motorized Shades

|