Achieving the goal of near net-zero energy consumption in research facilities over the next decade and beyond will be more challenging than efforts that so far have resulted in a 40 percent energy reduction for many. Getting to 80 percent savings can put them in range, and the best way to tackle this final, achievable savings is by addressing energy and water consumption together using new technologies like more efficient lab equipment and better data center cooling systems, according to Steve Frei and Paul Erickson, principals at Affiliated Engineers, Inc.

Water has traditionally been a low-cost utility, but compared to natural gas or electricity, its price is increasing the fastest and projected to continue increasing due to population growth and other factors. Frei noted that cooling energy represented 11 percent of the building total energy breakdown in one project, while cooling-related water use was 57 percent of the building total water breakdown.

“If you can reduce the building electrical loads, you can reduce the cooling towers. If you make a 1 percent reduction in energy consumption related to cooling, the amount of water associated with that cooling is 5 to 6 percent, so even a couple of percentage points can have a very dramatic impact.”

Much of what has already been accomplished was “low-hanging fruit,” adds Frei. “Going forward, it is going to be a little bit more challenging.”

The current thinking is that the last 40 to 50 percent of energy savings can be found inside the building, says Erickson.

“Better envelopes, better heating and cooling systems, better glass, and better fans and fume hoods have made a significant dent in energy consumption, but the limit is being reached. What remains are plug loads, or direct consumption, which often represent 30 to 50 percent of a building’s energy consumption.

“That is a pretty big piece, so that is where we see the next big opportunity.”

Much Has Been Accomplished

From 2005 to 2015, energy consumption in most U.S. laboratories was reduced by 30 to 40 percent due to innovations like high-efficiency fume hoods, revised air quantity standards, and electrical load rightsizing.

High-efficiency hoods allowed face velocity to be reduced from a typical 100 feet per minute to 60 to 80 feet per minute, significantly reducing how much air is necessary in ventilation-driven spaces. Automatic sash closing is now being put into a growing number of facilities.

A reevaluation of the minimum air change rates needed to keep laboratory air adequately safe and clean for researchers has led to more customization. Previously, as many as 12 air changes per hour were required, but many institutions and organization are setting rates at 6 ACH, and specialized monitoring equipment allows rates to be even lower based on occupancy and active monitoring for contaminants.

A dozen years ago, lab space electrical loads were assumed to give off heat at 10 to 15 watts per sf, notes Frei, with lighting loads, people loads, and window loads added to that total. Now, designers measure the actual heat gain, which can be as low as 2 to 3 watts per sf, requiring a lot less air for cooling.

Efficient energy recovery technologies also have contributed to the reduction, notes Frei. “We take some of the energy and transfer it from the exhaust air stream into the incoming air stream, and in the winter we don’t have to heat the building as much, or in the summer to cool it as much.”

Lab Equipment: The Next Frontier

Achieving the final energy reduction toward net zero will require tackling lab equipment, says Erickson, but that presents several challenges:

- Lack of alternative products

- Procedural issues: “The people purchasing equipment don’t think about energy usage; they think about how fast they can get it there and what is the cheapest product.”

- Operational issues

- Lack of incentive

- Limited data on equipment energy and water performance

When looking at lab equipment, it’s important to narrow the focus, he notes. Commodity equipment probably won’t get much development focus. Specialized equipment, like growth chambers and MRIs, are often customized, with limited interest in increasing efficiency. Small energy users probably aren’t worth the effort required to change the designs. That leaves a set of items worth tackling: freezers, data centers, bulk sterilizers/autoclaves, and tunnel/glass/cage rack washers.

A new generation of energy-efficient ultra-low-temperature freezers (ULTs), such as one based on the Stirling engine and one using a variable speed compressor, promise an almost unheard of 50 to 60 percent energy reduction. The former has been delivering results for many organizations. The latter is just now coming to market, says Erickson.

The Stirling ULTs use the free-piston Stirling engine, a 100-year-old technology, to continuously modulate temperature without using oil or moving parts. The units operate on a fixed amount of helium gas that is transferred back and forth between a “cold” and a “hot” end of a long cylinder. The gas never leaves the unit, so there is no need for exhaust. The unit also uses an external heat source, which could be anything from gasoline to solar energy, according to company information.

Thermo Scientific’s ULT technology uses two cascading compressors; historically, one compressor lowers the temperature to minus 40 degrees Celsius and the other takes the temperature from minus 40 C to minus 80 C, says Frei.

“The one that was typically cycling on and off to keep setpoint at minus 80 C is replaced by a variable speed compressor (in Thermo Scientific’s model), so it can modulate smoothly up and down, and by doing so saves quite a bit of energy. The technology has been used in building chillers for a while, but this is the first time the concept has been used in smaller refrigerators; that’s part of the advanced technology.”

Bob Cowan, director of facilities and operations at the Fred Hutchinson Cancer Research Center in Seattle, says his facility has been using Stirling ULTs for two years and currently has 60 on campus. He estimates they save $15,000 to $20,000 per year in energy costs. “That’s just on freezer energy consumption,” adds Cowan. “There’s additional savings on cooling the buildings, because the units don’t produce as much heat.”

The ULTs come with a slight cost premium, but Fred Hutchinson is replacing old freezers with ULTs as they fail, and also is getting utility rebates that help offset the cost. The ULTs have several other significant advantages, says Cowan:

- They are much quieter, so can be located where freezers couldn’t be located before.

- The units are much smaller and lighter, so are easier to transport and use as “loaner” freezers.

- They can operate on either 220-volt or 120-volt connections by simply switching a cord.

- They use ethane refrigerant, and less of it than traditional freezers, so are better for the environment.

“The real benefit of these new generation ULTs is yet to be realized,” adds Cowan. “The real benefit is that it will significantly reduce the plug load and, hence the heat load in the equipment corridors. And by reducing plug load and heat load, you can downsize much of your equipment.”

“This is a big opportunity for savings, and we don’t usually see savings opportunities like this from any single technology. Really, on the HVAC side or architecturally, this is significant,” adds Erickson.

Data centers are another big energy savings opportunity. With the increase in quantitative research, a lot more lab spaces require heavy computing. A range of options affects infrastructure needs: towers at desks, server closets, centralized data centers (either building-wide or campus-wide), and cloud-based computing.

Giving researchers an array of Energy Star approved equipment choices (instead of requiring everyone to use the same pieces) is one way to start addressing efficiency, says Erickson.

For facilities with a more administrative or teaching component, computer labs are a good focus area. Instead of arbitrarily assuming a 2-watt-per-sf equipment load, facility designers can now come up with strategies that reduce the load to 0.5 watts per sf.

“We can downsize your cooling system and your electrical system. It is a big opportunity, not just in the energy but also in thinking up front.”

Data closets can be made more energy efficient by putting a chimney on them. Instead of all the warm air exiting the servers and mixing with cold air dumped by a fan coil, chimneys pull the heat off the top, and the air coming in can be much more effective, says Erickson. These chimneys recently achieved a 3 percent savings on a large lab project, which is significant for any one strategy.

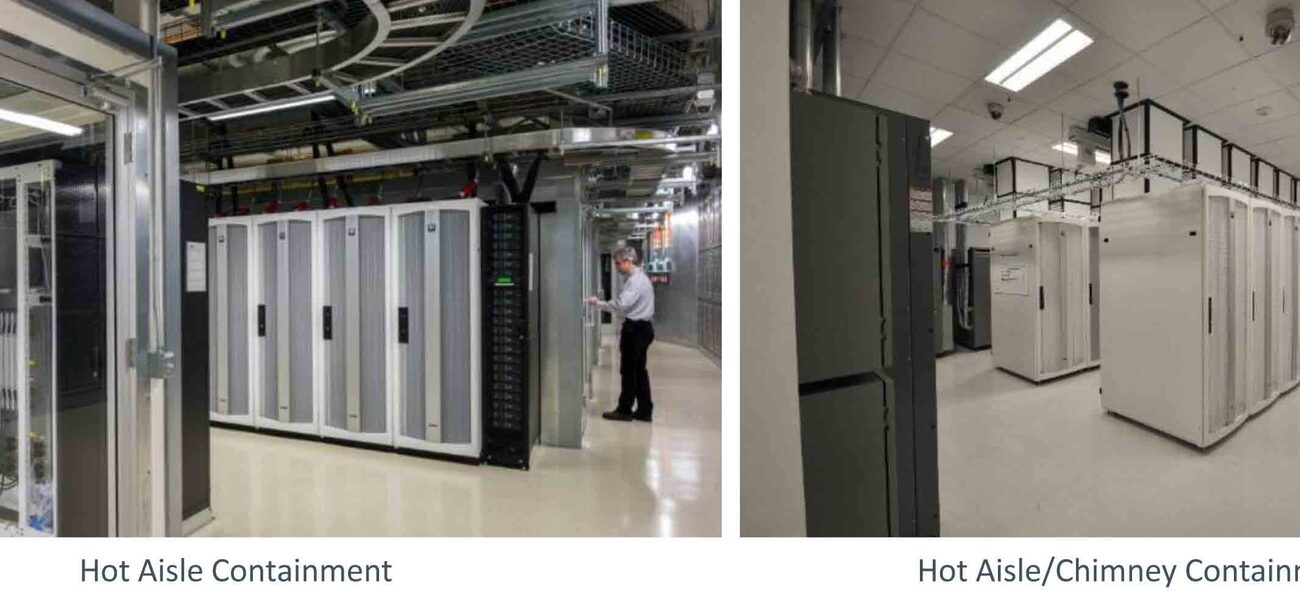

An even more significant opportunity for centralized computing is hot aisle containment, or hot aisle chimney containment, he adds. Similar to the server strategy, the idea is to increase the effect of the cooling. With hot aisle containment, the racks of computers draw air in from a “cold aisle” in the front and discharge to a “hot aisle” in the back. In lieu of the hot aisle, chimneys can be used to isolate the heat.

“You keep the two airstreams separate. By keeping the airstreams separate, you use air once and take it away, so you can get by with a lot less air (and energy),” explains Frei.

A hot aisle containment system at Kansas State University reduced the proposed airflow from 300,000 cubic feet per minute (cfm) to 60,000 cfm, translating to a savings of almost $400,000 a year in utility costs, says Erickson.

Whether chimneys or hot aisle containment work better for an institution depends upon the layout, he adds. Chimney systems are a bit more flexible than hot aisle containment, which requires the servers to be oriented a certain way. But, more ceiling space is required for the chimneys.

Sterilization and wash equipment represent the final piece of water/energy reduction possibilities. Cage wash and tunnel wash “reclaim” systems can take the hot effluent expelled from the machines, cycle it through a heat exchanger inside of a preheat tank, and preheat the next batch of water. The system adds a small capital cost to the equipment, but it can have a big impact, says Erickson.

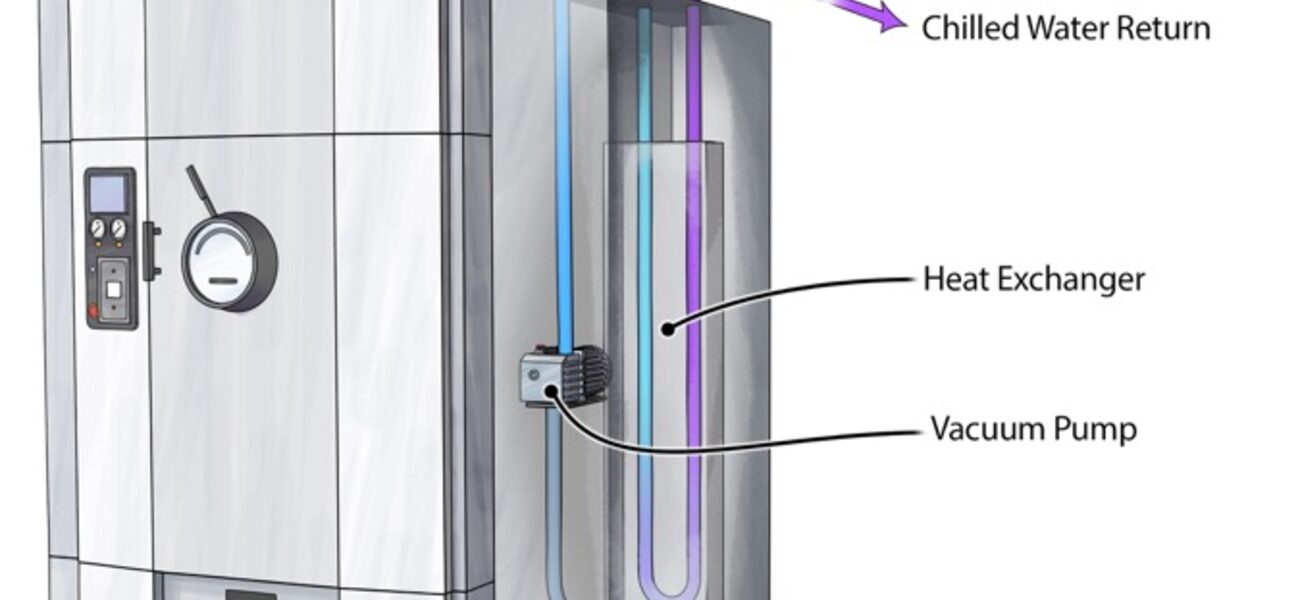

Facilities with centralized, sterile cage wash/tunnel wash, glass wash, and autoclaves that use city water must cool the effluent before putting it down the drain, and traditionally use hundreds of gallons of cold water to do so. But, if they utilize a closed-loop system to recirculate the water, these facilities can pull the heat away more effectively and save water, says Frei.

“We can recirculate either cooling tower water, water from a geothermal ground loop, chilled water from a chiller, or water from some other source,” adds Erickson.

The owners of a planned University of Pittsburgh Medical Center project wanted to save on water and sewer charges, so they opted to use a chilled water system. This solution meant more equipment cost up front for the recirculation heat exchangers and more energy costs for the chilled water used, but the 80 to 90 percent reduction in water tipped the balance, saving nearly $40,000 per year after paying for the additional energy cost, says Erickson.

“Even where water rates might still be relatively low, they are changing quickly enough that it is beginning to tip the balance if you look at both water and energy rates simultaneously,” he adds.

A 400,000-sf hospital facility on a greenfield site in Madison, Wisc., recently realized a 70 percent reduction in potable water usage with strategies such as heat recovery chillers, energy efficiency measures, water efficiency measures, recapturing condensate (the moisture wrung out of the air from air handling units), and rainwater usage.

“That is in a place where water is cheap and it doesn’t drive those decisions. It is really a shift that we are seeing that provides a huge opportunity,” says Erickson.

Change Management Required

Achieving the final percentage of energy reduction requires not only embracing new technologies, but also change management strategies. One challenge is that not every owner or every institution is ready to take the necessary steps, notes Erickson.

“We find that we may come into a project with the 10 best strategies, but in order to get any one institution to adopt all 10, change management can be the biggest challenge. Begin to think about how you can engage users, how you can engage different types of champions or stakeholders.”

Various sustainable lab planning groups are doing great work and are happy to share what they do, he adds. And, don’t be overwhelmed by all of the opportunities, but begin by taking reasonable steps that work for a particular institution.

“I think the key is finding a good team, finding people who are going to be champions. It is going to take some change within the organization. As you are doing that, think about the water piece as well. Think not only about equipment, but also about how you can do things a little bit differently. Not just to save energy but in some cases to downsize systems, fit it all into smaller spaces, and hopefully do so without adding cost to the project,” says Erickson.

Adds Frei: “Going forward it is going to take a real team effort, particularly with owners and other stakeholders, to change some of these purchasing policies that we as designers have very little control and limited influence on changing, but that is clearly where the opportunities are going to be if we are to further reduce how much energy and water is consumed.”

By Taitia Shelow

This article is based on a presentation Frei and Erickson gave at the 2015 Tradeline Strategic Facility and Space Planning for Science and Research conference.