The 280,000-sf Center for the Sciences and Innovation (CSI) is the largest development ever undertaken on the campus of Trinity University. The phased project includes 150,000 gsf of new construction, an 80,000 gsf gut renovation of Cowles Life Sciences Building, and a light renovation of the 50,000-gsf Marrs McLean Hall, to create an integrated academic complex. It houses teaching and research labs, an engineering studio, greenhouse, vivarium, and an Innovation Studio, and is home to the university-wide Entrepreneurship Center.

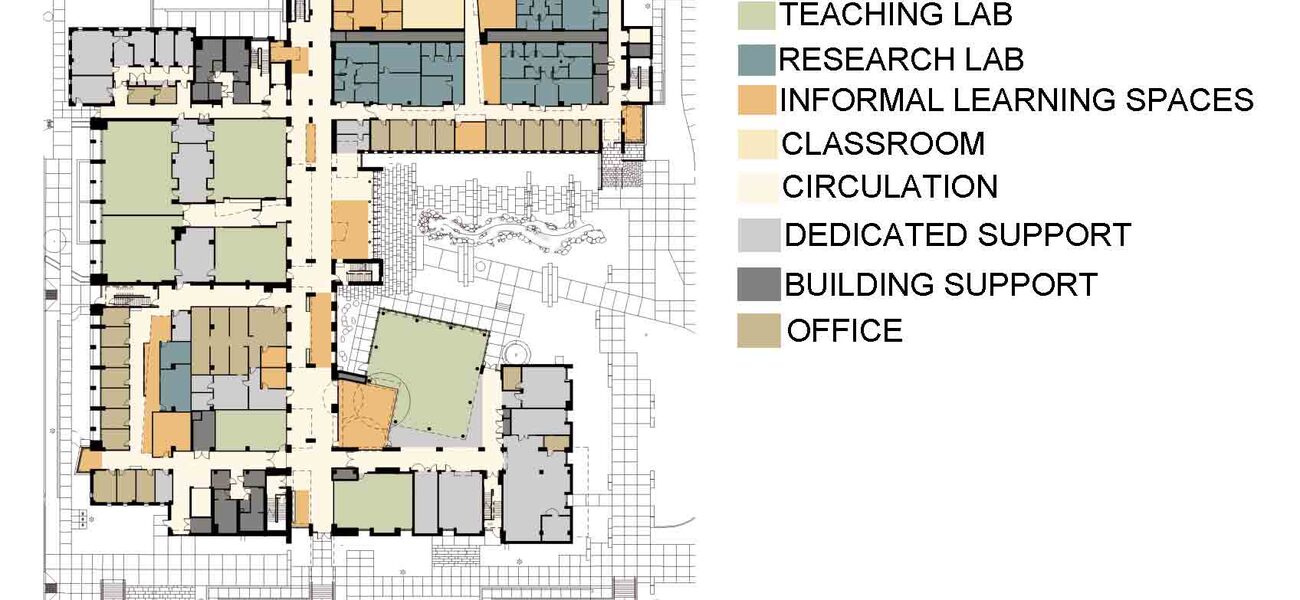

CSI features glass-walled classrooms, study areas, and faculty offices; 24 teaching labs and 43 research labs; café and gathering areas to stimulate student/faculty interaction; and a grand entrance, atrium, and elevated walkways.

The facility supports interdisciplinary teaching and research in engineering science, biology, chemistry, psychology, and computer science, as well as biochemistry and neuroscience. The new structure includes a bridge connecting it to Marrs McLean Hall, which houses geosciences, mathematics, physics, and astronomy. The renovation of Marrs McLean includes construction of a new entry and community spaces.

An extensive use of glazing puts science on display throughout interconnected neighborhoods of classrooms, laboratories, and offices. The building’s spine serves as a thoroughfare that connects the sciences to each other and to the center of campus.

The building itself serves as a laboratory: Soils on the green roof are tested for temperature to see which native grasses are the best at controlling heat, and an engineering faculty member is studying the capturing of condensate to reuse the water. Multiple sub-meters continuously monitor the building’s performance, enabling students and faculty to track and analyze the consumption of electricity, water, natural gas, and other resources; and engineering students are analyzing building systems to see where additional efficiencies can be leveraged.

Teaching labs are designed to engage students immediately in active science, using modern equipment that supports authentic research experiences. The “Cube” Innovation Studio—the 8,500-nsf engineering project lab—addresses the full spectrum of the engineering process: thinking, modeling, and making. The thinking spaces are comfortable and simple, like a lounge, where students and professors can discuss ideas. The modeling space supports team-based work with a computer visualization space and modeling areas for groups of five to seven. That area seamlessly flows into the making space, a two-story lab that can accommodate 10 groups of five to seven people, surrounded by shops and storage. All freshmen are required to take an interdisciplinary entrepreneurship seminar that meets in the Cube.

The facility is certified LEED Gold. A major sustainable feature is water conservation. The grasses on the green roof are irrigated by a storm water cistern, backwash from the reverse osmosis filtration system, and air conditioning condensate; and the building uses 100 percent gray water for flushing low-flow toilets. These measures and others earned a $1.3 million energy rebate; the building uses 35 percent less energy than an equivalent code-compliant design, and saves the University approximately $230,000 in annual utility costs.

| Organization | Project Role |

|---|---|

|

EYP Architecture & Engineering

|

Architect

|

|

RVK Architects

|

Local Architect

|

|

Joeris General Contractors Ltd.

|

General Contractor -- Phase I

|

|

Vaughn Construction

|

General Contractor -- Phase II

|

|

Jaster Quintanilla

|

Civil / Structural Engineers

|

|

Cavanaugh Tocci

|

Acoustics

|

|

Campbell McCabe

|

Security

|

|

Horton Lees Brogden Lighting Design

|

Lighting

|

|

Rialto Studio

|

Landscape Architecture

|

|

Haldeman-Homme, Inc.

|

Lab Casework

|

|

Automated Logic

|

Building Controls

|

|

McQuay International

|

Air Handlers

|