Bertelsmeyer Hall, a new facility for chemical and biological engineering under construction on the campus of Missouri University of Science and Technology, combines lab and specialized research space in one wing, with classrooms and offices in a separate wing. "Segregating the classrooms and offices from the labs allows us to make a lot of interesting decisions, including a completely different structural system. Identifying the impact of the specialty research spaces is key, and on this project it really drives how the building is shaped and how the spaces interact,” says Andy Stepp, senior principal with The Clark Enersen Partners, the Kansas City firm that designed the building.

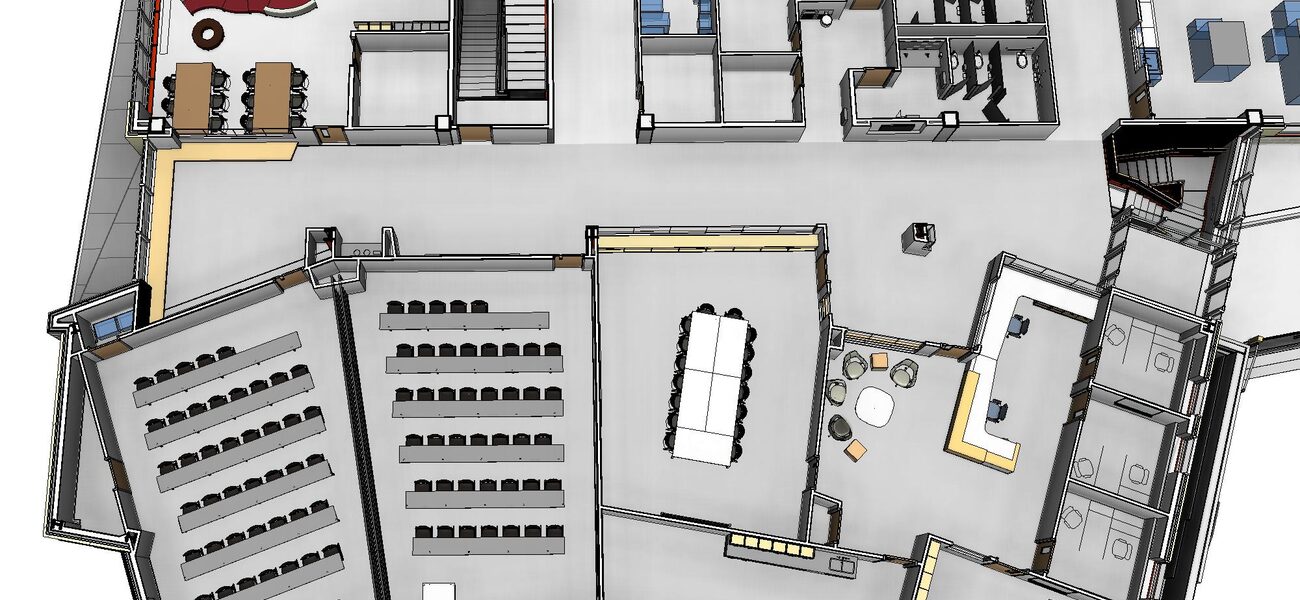

Bertelsmeyer Hall has a cohesive appearance and design, but each wing is built differently and can operate as a separate unit. The classrooms and offices, located in the south wing and accounting for 40 percent of the building, are constructed of steel decking and cast floors. The north wing, devoted to labs and specialized research space, uses cast-in-place concrete to support heavy apparatus and reduce vibration in lab areas containing delicate instrumentation. “The building is organized around space types. The flexibility is driven by the layout and the unique engineered systems in each wing,” says Stepp.

The design impacts not only structural materials, but also air handling systems and building security and access. Separate air-handling systems keep chemicals and contaminants from migrating from the labs to the classrooms. In terms of building security, staff can control access to areas involving hazardous materials, restricting students to the learning areas. “If you have 150 undergraduate students coming to class, you don’t want them entering areas involving radioisotopes. You can draw a hard line through the plan, providing opportunities to create public and secure spaces,” says Stepp.

With 8,000 students—2,000 in graduate programs—the Missouri University of Science and Technology in Rolla, Mo., enrolls between 400 and 500 students each year in its rapidly growing engineering and science programs, currently housed in 20,000 gsf, roughly one-quarter of Schrenk Hall. In 2006, Clark Enersen Partners contracted with the university to renovate Schrenk Hall. Several years into the renovation, the university received a donation allowing construction of an entirely new building for chemical and biological engineering, on a site about 150 yards across the parking lot. Upon completion of Bertelsmeyer Hall later this summer at a projected cost of $17.6 million, the chemical and biological engineering programs will move from Schrenk Hall, and renovations on that building will be completed.

“We’re not only giving them additional space, but also research spaces with greater capability for flexibility in space planning and adaptability of mechanical and electrical systems. It’s not just space to grow into, but also provides the infrastructure to adapt as their research changes,” says Stepp.

Specialty Research Space

Four programs in the chemical and biological engineering program require unique or specifically designed space:

- A radioisotope lab, used for research on nuclear reactors.

- High bay research space to accommodate large or heavy equipment and apparatus.

- Space meeting class I, division II requirements, as defined by OSHA, for research involving a high risk of explosion or flammability.

- A unit operations area, for modeling real-world engineering solutions and work environments.

The radioisotope lab accommodates research involving radioactive materials. “We met one researcher who creates scale models of nuclear reactors using cesium markers to track how marbles move through reactors columns. He was working in an area that did not shield his work, and he was having trouble meeting the requirements of the university environmental health and safety team,” says Stepp.

The new lab, located in the basement of Bertelsmeyer Hall, features a 9-foot-deep, below-grade pit to house the reactor columns. A primary drainage loop surrounding the pit collects storm- and groundwater, with a secondary holding area, without a sump, to contain any hazardous spill.

The class I, division II space in Bertelsmeyer Hall is rated for flammable and explosion hazards. Work in this area may off-gas carbon dioxide, methane, and hydrogen, creating an explosion risk. “The solution we came up with is to basically build a bunker in the lower area of this building,” says Stepp.

In case of an explosion, a weak point in one exterior wall of the bunker blows out into an unoccupied area to the north of the building. An 8-inch pre-cast plank forms the top of the box. “We had to decide whether to build that reinforcement into the cast-in-place structure or leave space so that after we build the cast-in-place structure, the pre-cast plank slides in from the side, which is what we ended up doing,” says Stepp. Otherwise, there would be no way to remove the formwork, and it would have to be abandoned in place.

Other safety measures include a push-button-activated exhaust fan, an elaborate gas detection system, and a manual override allowing occupants to kill power to the entire suite if there is an accident. “We are monitoring the methane, oxygen, and carbon monoxide levels in the space, so that in the event of a catastrophic happening, people know there is something wrong and get out,” says Adam Golubski, principal and mechanical engineer at Clark Enersen. “Everything is explosion-proof in the class I division II space.”

The unit operations area in Bertelsmeyer Hall more than triples the current 800 sf available in Schrenk Hall, and also includes high bay space for pilot-scale models of oil refineries or chemical plants. “The heart and soul of the chemical engineering program is unit operations. Every chemical engineering program in the country needs this type of space to set up apparatus that mimics what students will see in the real world. It requires a large flexible space that can accommodate building very tall apparatus or pilot projects,” says Stepp.

Flexible Design in Lab and Learning Spaces

A modular design in the lab accommodates alterations as research needs and equipment change. “Modular design allows us to create building blocks for lab design. We can easily change the layout from the current design featuring three lab spaces shared by two or three researchers, to create several smaller labs,” says Phil Walter, principal and electrical engineer at Clark Enersen. The design also adapts easily to accommodate large equipment or isolate specialized work areas, limiting the impact on other parts of the lab.

For this project, modules are 11 feet wide by 24 to 36 feet long, with a 5-foot aisle. Walter notes that decreasing laboratory module square footage is not necessarily a quick fix to trim the budget, since MEP costs remain relatively unchanged. “You might achieve a 9 percent reduction in area if you go to a 10-by-30-foot module, but you still need similar HVAC systems, piping, and electrical load density. You might save a little on materials, but your effort is potentially better spent seeking reductions in other parts of the building and keeping the modules within a standard size,” explains Walter.

The lab ceilings remain open to provide maximum flexibility and functionality, accommodating floor and bench-mounted equipment or traditional peninsula benches with shelving. The overhead electrical busway system easily adapts to changing electrical needs. “With the electrical service, it is critical to plug and play and not have to pull wire every time they get a new piece of equipment. Most of the power in the lab environment comes from overhead, and you quickly modify electrical equipment feeds in a variety of different ways,” says Walter.

Flexibility is also important in the learning wing, which includes classrooms, a student lounge, a 150-seat auditorium, office space, and a department conference room that doubles as a small seminar room. A 188-seat lecture room can be divided to create two 44-seat classrooms via a specially designed retractable wall that drops from the ceiling. “Usually, moveable walls move horizontally. In this case we employed two vertically acting moveable partitions. It’s a novel approach to subdivide the rooms,” says Stepp. While this style costs about twice as much as horizontal partitions—about $100,000 for the two walls—it creates space within the room by eliminating the wall pocket needed to stow the partitions.

The building includes 3,430 gsf of geothermal space and houses one of four regional pumping stations for the campus geothermal loop. As part of achieving LEED certification credits, a condensate reclaim system will gather cold condensate from the air handling unit cooling coils in the penthouse and pump it back to the geothermal plant cooling tower. While re-using the water is desirable as a green concept, the system still costs money to operate. “The costs of the pumping equipment maintenance and electricity are estimated to be about $10,000 more than just paying for the water, but the owners really wanted to re-use this water rather than dumping it down the drain,” says Golubski.

By Mary Beth Rohde

This article is based on a presentation by Stepp, Walter, and Golubski at the Tradeline 2013 College and University Science Facilities Conference.