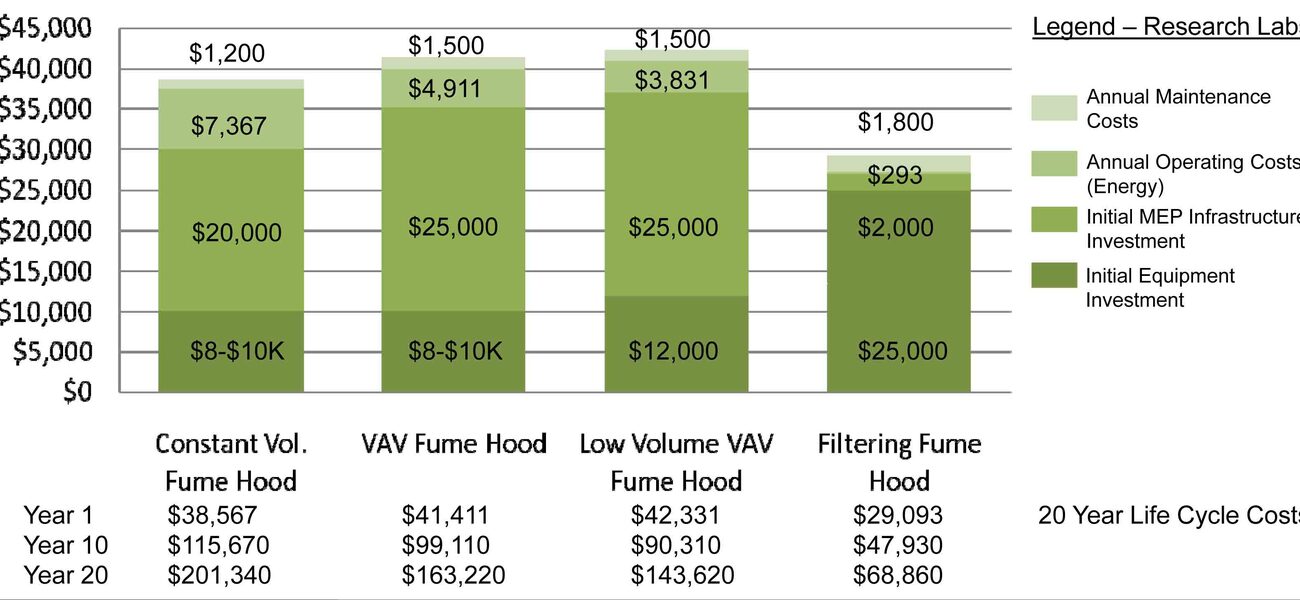

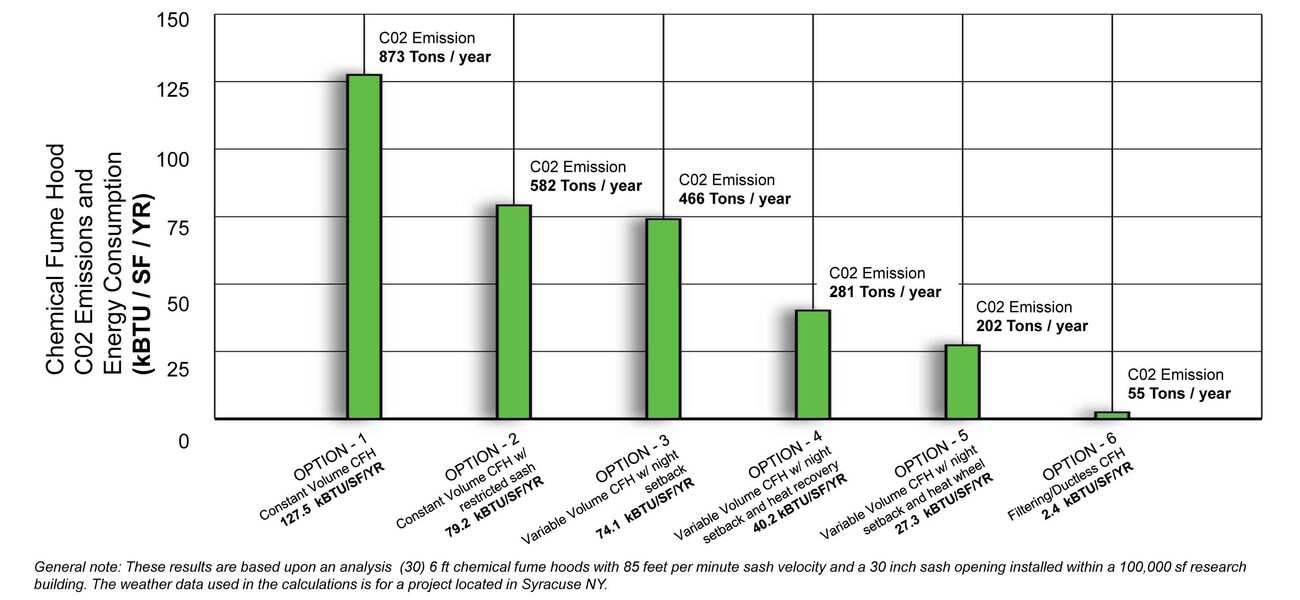

When compared to constant volume hoods (CV), variable air volume (VAV) hoods, and high-performance VAV (“low-flow”) hoods—based on a hypothetical 30-hood, 100,000-sf building—filtered hoods generate significant initial, operational, and environmental savings. This matters because chemical fume hoods used in commercial, research, and instructional laboratories are among the country’s biggest energy hogs. Each of the nation’s estimated 750,000 fume hoods costs labs on average $5,600 in annual energy costs while emitting an average of 15 to 20 tons of carbon dioxide and 150 pounds of hazardous chemicals into the atmosphere every year. Though next-generation filtered fume hoods have the potential to reduce first costs, operating costs, and emissions, knowing when they are appropriate depends on several factors, including the chemicals handled, hood density, and building infrastructure.

“We looked at six different scenarios for 30 hoods, in terms of first costs, including head-end infrastructure, controls, ductwork, and distribution,” says James Blount, principal with Cambridge-based Ellenzweig. “Then we looked at energy performance, the requirements for makeup air, and the total operational costs, including maintenance.”

In that comparison—conducted by Ellenzweig in collaboration with BR+A Consulting, R.W. Sullivan Engineering, and Vanderweil—filtered hoods outperformed other technologies in both first costs and ongoing operational costs.

From an environmental point of view, based on a study for a 100,000-sf research building with 30 chemical fume hoods, the filtered hood scenario is notably superior, consuming only 2.4 kBTU of energy per-sf/per-year, compared to an average of 127.5 kBTU per-sf/per-year for constant volume hoods, and 74.1 kBTU per-sf/per-year for VAV hoods with a nighttime setback. They also generated only a fraction of the CO2 compared to competing technologies, emitting only 55 tons of CO2 a year versus the 873 tons of a constant volume hood scenario.

Does it Work for You?

How, then, do you know if filtered hoods are the right solution for your lab?

“The answer is, it depends,” says Kenneth Crooks, director of GreenFumeHood technology at Erlab. “Are you using chilled beams or a cooled reheat system? What is your fume hood density? Is it a research lab? Is it a teaching lab? There are a lot of things that impact the decision.”

While some organizations will be attracted to filtered hoods for their low environmental impact, for most organizations, total cost of ownership and return on investment are the deciding factors.

“If your hood density is high enough that you can significantly impact energy consumption by using filtered fume hoods then, yes, there is a financial incentive,” says Crooks.

Another consideration is ensuring that none of the chemicals intended for use in the lab are on the manufacturer’s list of chemicals that are not appropriate for use in a filtered fume hood, a.k.a. “the short list.”

“Every manufacturer of a filtering fume hood, even ductless hoods, will have a short list,” says Crooks. “This is a list of chemicals that are not captured by that filtration; chemicals with very low boiling points—usually below 25 Celsius—and low molecular weight, such as hydrogen, methane, and nitrogen monoxide. Also, highly toxic chemicals like cyanide and mercury.”

There are also certain applications filtered hoods are excluded from.

“Any specialty hood—like a perchloric acid hood, an acid digestion hood, or a radio isotope hood with very specific requirements—is definitely not a filtered fume hood candidate,” says Crooks.

Crooks also recommends making the first hood in any chemical lab ducted.

“Your first hood in the lab should be a ducted hood, because you are going to need it to achieve your air change rates,” he says. “That is your safety hood. You are also going to need it for flexibility if you bring something new into the lab five years from now.”

Filtered vs. Ductless

Despite the fact that filtered and ductless fume hoods share the same feature of not attaching to an air duct, the two technologies are very different, primarily in that filtered fume hoods have two filters instead of one. The second filter—which sits at the top of the technology stack and has all the capability of the primary filter—functions as a redundant safety feature.

“No longer, as with the limitations of the ductless world, do you have to select a filter based specifically on the operation being done inside the fume hood,” says Crooks. “Filtered fume hoods offer one universal filtration system. There are now carbon-based filters that can handle acids, solvents, and bases simultaneously.”

Another feature that sets filtered fume hoods apart from ductless hoods is the placement of sensors between the primary and the secondary filter that detect acids and other compounds. These sensors identify when the first molecule breaks through the primary filter, triggering an alarm indicating the need for a primary filter change.

Filtered hoods also feature temperature sensors that can automatically shut down the fans if there is a fire inside.

When and Where

Obviously, safety is the first concern when selecting fume hoods. If filtered fume hoods are confirmed to be a safe solution, the next consideration is cost.

“Looking at it just from a dollar standpoint,” says Crooks, “if your hood density is low enough that filtered hoods don’t reduce the exhaust air, (for example: if you have a large life science lab where there is one hood in an alcove in the center) then going filtered will just add to your operational costs by requiring you to change filters every two to three years.”

“Also, if your cooling requirements are greater, and you need more cool-reheat, then filtered fume hoods aren’t going to reduce your energy consumption,” says Crooks. “That would drive you to a ducted hood.”

However, filtered hoods can often be the ideal solution for high hood-density labs, lab renovations, and retrofits.

“If your makeup air system is already overtaxed, like many labs, then filtered fume hoods are worth a look,” says Crooks. “Also if there are structural challenges to installing ductwork or other issues that are limiting airflow.”

Case Studies

When Framingham State University added a 70,000-sf instructional lab building to an aging science complex, filtered hoods were initially considered but excluded, only to be reintroduced later.

“The project was very challenging in that they wanted to maintain connections to the existing building,” says Blount. “The entire 170,000-sf building had about 60 fume hoods, which is very dense for a teaching research building. A lot of the energy costs and long-term paybacks were right in line with the first costs for the infrastructure. So we started to look at filtering fume hoods as a value engineering option. After meeting with the scientists to do a lifecycle analysis, we determined that using the same number of filtered hoods would result in a 25 percent reduction in head-end infrastructure cost. That was including the ductwork, the controls themselves, and the head-end equipment.”

In a less fume-hood-dense example, the Bridgestone Technical Center in Akron has 11 filtered hoods and one floor-mounted ducted hood.

“Before committing to buy all 11 hoods, they tested one with everything they could throw at it just to make sure it would work for them in the future as they continue to invent the next generation of racing tires,” says Crooks. “That testing included 306 chemicals over 20 months.”

Bridgestone’s biggest issue was containing mercaptan—the smell put into natural gas—which had led to neighborhood complaints and complaints of re-entrainment in the old research building.

“That was the first issue they came to our lab with and said, ‘Solve this, and we’ll talk,’” says Crooks. “We put it in the hood, popped it open, and you couldn’t smell a thing. We actually evaporated everything that was in the vial with no problem whatsoever. We estimate they’ve already saved close to $150,000, and, in their estimation, they will continue saving about $5,000 a year per hood.”

“The capacity of new filters is phenomenal,” says Crooks. “Is it universal? Is it a silver bullet? No. There are no silver bullets. Deciding if the technology is right for your lab will always depend on the situation.”

Filtration Innovations for the Future

Filtered fume hoods have spawned an innovation that uses similar technology to improve the indoor air quality of labs with room-level filtration mounted in the ceiling.

“Common feedback from those using filtering fume hoods is that their lab has the best indoor air quality of any room in their building,” says Crooks. “That’s because the filtering fume hood is running and scrubbing the air all the time. The idea is, why not take that same fan and filter module and mount it in the ceiling? If you are a researcher and you have a spill, a ceiling-mounted filtration unit isn’t going to protect you. But it’s a great way to increase decay rates and remove that lab smell.”

Ceiling-mounted filtration systems have just finished development by different manufacturers.

“We are trying to determine the optimum spot in the room where you can get the benefit of 10 air changes but at the operating cost of four,” says Crooks.

By Johnathon Allen

This report is based on a presentation by Blount and Crooks at Tradeline’s 2014 International Conference on Research Facilities.

| Organization |

|---|

|

Erlab, Inc.

|

|

BR+A Consulting Engineers

|

|

R.W. Sullivan, Inc.

|