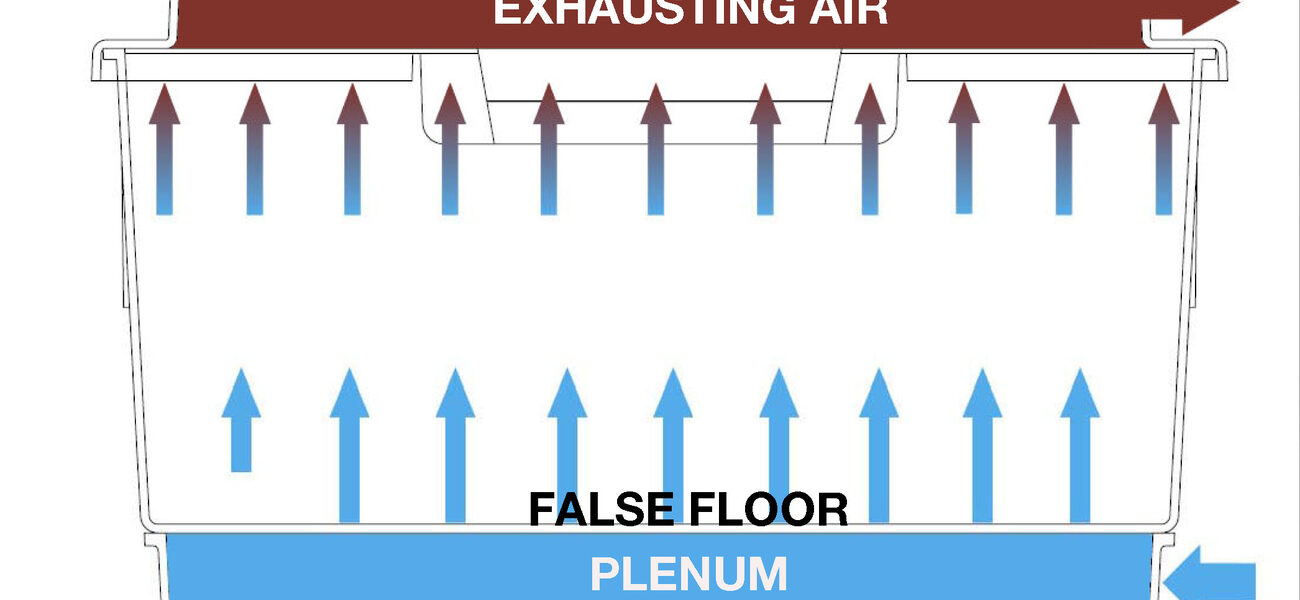

Newly designed, individually ventilated cages (IVCs) can potentially reduce HVAC costs by up to 75 percent and improve living conditions for the mice inside. The bedding sits on a perforated false floor, which is suspended over the normal cage floor to create an air plenum. Air percolates up from the plenum, through the false floor and bedding, and out the top of the cage. This airflow maintains a low relative humidity in the cage and actively dries the bedding. Bedding that is damp, whether from urine or water bottle leakage, produces ammonia, which is not only harmful to the mice but unpleasant for the researchers who may have to breathe the same air.

There are two traditional styles of cage ventilation. In the first, air enters through the sidewall of the cage and exits out the top. In the second, air both enters and exits through the top. These methods usually use ventilation rates of 60 or more air changes per hour (ACH). That much air passing through a cage can chill and dehydrate mice, dilute pheromones, and create disturbing levels of vibration and noise in the cage. Further, the more ACH you use, the larger the supporting HVAC mechanical systems and costs will be.

The type of ventilation scheme associated with the ventilated racks can have its own pitfalls.

Air supplied from the room, circulated through the cages, and exhausted back into the room raises the room temperature due to the body heat of the mice, and increases CO2 concentrations and humidity. Ammonia expelled into the room also is harmful to humans and smells unpleasant. Most likely, it will require increased room ACH to make conditions more comfortable for the researchers.

Air supplied from the room, circulated through the cages, but exhausted directly out of the room eliminates some of those problems but adds the need to replenish the air in the room, which again requires raising the room’s ACH. Another solution—circulating air directly into and out of the cages without ever passing through the room—requires an entire secondary HVAC component and once again raises the total ACH.

ACH are costly to add. A study in 2011 reported that ventilation could cost as much as $9 per cubic foot per minute per year. “Your average rack, let’s assume, uses 50 cfm,” says Michael Semenuk, president of Lenderking Caging Products. “If we take that times the $9, we get a budget operating cost of $450 per year. If you have six racks in a room, it is $2,700 per year per room for the racks alone. As we all know, that $9 is not going down next year. It is probably going to go up.”

A Possible Solution

Lenderking’s design, currently in field testing, addresses the central problem of high ACH usage with its false-floor design. Blowing the air directly through the bedding—called Flow Thru BeddingTM—allows for a drastic reduction in the ACH required for a dry cage.

Seeking to prove this, Lenderking simulated a catastrophic bottle failure with completely saturated bedding. A traditional IVC (sidewall-in, top-out) operating at 60 ACH reduced the bedding moisture to 25 percent after 24 hours, but after 48 hours the bedding moisture remained stable at 25 percent saturation. Under the same conditions, operating at only 15 ACH, the Flow Thru Bedding design reduced the bedding to 10 percent saturation in only 20 hours, and in 36 hours the bedding was completely dry. “You would never know it had been wet,” says Semenuk.

The false floor in the cage requires an extra three-quarters of an inch of cage height to create the plenum underneath. A fringe benefit of this design is that even the total failure of a 16-ounce water bottle will not fill that space. “I doubt we will ever see cage flooding again,” he says.

Next, Lenderking tested the Flow Thru Bedding cage with five live mice, and monitored ammonia levels. “Most IVCs start losing their ability to dry the bedding adequately at about the tenth day, and that is when you start getting ammonia formation,” he says. At the end of their 21-day trial, bedding inside the Lenderking cage was still at zero percent saturation with no ammonia.

One notable exception in their test was an unplanned power failure on the 11th day. After this, predictably, moisture inside the cage rose to 12-15 percent saturation. “We just let the fans go back on,” he says. Shortly thereafter, the bedding inside the cage dried completely, as it remained for the duration of the test.

Unexpectedly, the mice inside the Lenderking cage consumed much less water. In their test of a traditional 60-ACH IVC, the mice emptied their 250-ml water bottle by the tenth day. Mice in the Lenderking cage went the full 21 days with no bottle change. “Can I tell you that is going to happen every time? No, I can’t,” says Semenuk. “But I do think that now you have a true 14-day closed cage where you do not have to disturb the cage in any way or break the barrier to service water.”

The Benefits of Low ACH

There is more to ACH reduction than potentially 75 percent lower HVAC operating costs. At only 15 ACH, the inlet velocity of air entering the plenum is only 21 fpm. To compare, the human standard for “still air” is 39-50 fpm. Not only that, but because the air passes not through one aperture but thousands, the velocity through any one hole is only 0.003 fpm, a speed so low that even notoriously sensitive mice are unlikely to notice.

Mice in the Lenderking cages can expect a completely dry, ammonia-free environment, with reduced vibration and noise rates, reduced chilling and dehydration, and reduced pheromone dilution. All these successes come at remarkably little cost. “I can’t think of what the downside might be,” says Lou DeTolla, chief of veterinary resources at the University of Maryland School of Medicine, where they are currently testing the design.

Semenuk suggests a number of other logical benefits from the Flow Thru Bedding cage design, including lower MEP costs on construction and replacement, a better macro-environment for research personnel, and even reduced water usage at the end of a cage cycle, as the completely dry cages will take less to clean than traditional damp, ammonia-laden IVCs. The cages’ reduced energy consumption could assist facilities seeking LEED certification, grants, subsidies, or tax breaks.

Perhaps most exciting for researchers is the potential for longer cage change intervals. Although they are not yet ready to release their test results, DeTolla suggests that the Lenderking cages may be able to go as long as a month between cage changes. Still, he is pleased by early results. “If the Lenderking IVC works as well as we think it will,” he says, “it will help to revolutionize the mouse care industry.”

By Braden T Curtis

This report is based on a presentation by Semenuk at Tradeline’s Animal Research Facilities 2012 conference.

| Organization |

|---|

|

Lenderking Caging Products

|