The Measurement, Materials & Sustainable Environment Center (M2SEC) at the University of Kansas School of Engineering is a 46,735-sf interdisciplinary engineering research facility focused on energy/transportation, global change, composite materials/technology, and sustainable building practices. Funded in part by a $12.3 million National Institute of Standards and Technology grant, the flexible research environments include:

Biological Materials Laboratory – Dedicated to the development of biomaterials, such as tissue engineering and cartilage regeneration, as well as new drug delivery. The lab allows collaboration among engineers, scientists, medical professionals, and industrial partners.

Carbon Fiber Composites Laboratory – Allows students and the KU Center for Remote Sensing of Ice Sheets (CReSIS) researchers to design and construct aircraft, sensors, and systems with ground-penetrating radar that captures data and generates accurate 3D maps of polar ice sheets down to bedrock. The lab contains a composites oven that is used to cure entire airframe structures and vehicle components.

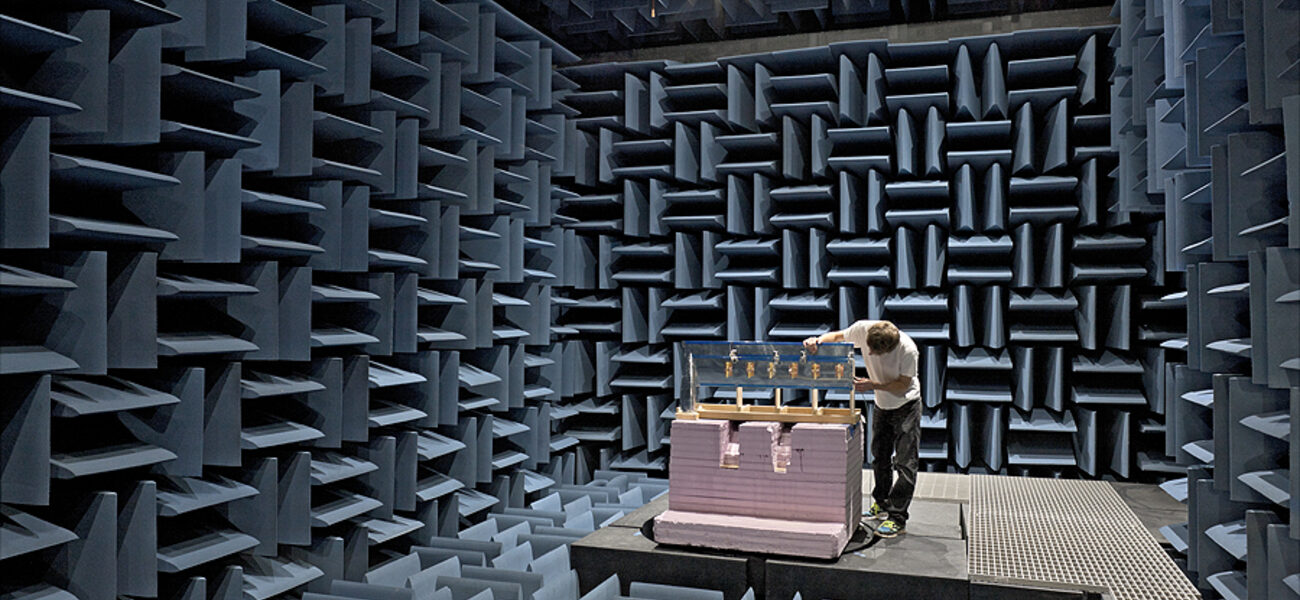

Acoustics Laboratory – Has one of the largest anechoic (EMI/EMC) chambers in the region. The anechoic chamber is an isolated 15-by-35-by-15-foot room that allows antenna characterizations and electromagnetic interference and compatibility studies in a controlled environment. The chamber walls, ceiling and floor are covered in anechoic foam wedges, which dampen electromagnetic wave signals and provide an interference-free environment.

Acoustic Reverberation Suite – Used to evaluate alternative test methods for noise reduction and test noise reduction qualities of new materials, including aircraft fuselage sidewalls and new building walls.

Phase Change Materials Laboratory – Researches ways to develop more efficient building envelopes. Two exterior walls of the building are lined with 63 interchangeable panels that allow testing and monitoring of different construction and building materials and provide better ways of controlling building heating and cooling. Sensors connected to the panels track heat transfer and allow evaluation of heat transfer efficiency.

Multi-Dimensional Fracture & Fatigue Laboratory – Tests construction industry structural members, such as bridge spans, as well as aerospace and biomedical components and systems in three dimensions. It features a specialized structural testing “strong room” containing multiple ceiling and floor anchors to mount test specimens. Each anchor can handle a tension force of 200,000 lbs (or 200 kips). The entire strong room structure is isolated from the building to minimize vibration that could affect nearby experiments.

Three Biofuels laboratories and a rooftop greenhouse – Produce, test, and certify alternative fuels extracted from algae. The Feedstock to Tailpipe Initiative© under KU's Transportation Research Institute strives to find economically and environmentally sustainable methods for the largescale, stable production of green gasoline, diesel, and jet fuels from algal feedstock.

Test Cell Laboratory – Includes a 350-hp dynamometer used to test the mechanical and emissions characteristics of the fuel produced in the biofuels lab. The test cell is also designed to provide regenerative power back into the grid.

The facility was designed to exceed ASHRAE 90.1 baseline energy efficiency standards by a minimum of 30 percent to meet the University of Kansas standards for energy efficiency. Major building components supporting this energy efficiency include:

- Chilled beams.

- Low velocity coils and filters.

- The energy stored in the building’s exhaust stream will be recovered and used in the preheat system.

- Stormwater reuse system and green roof research

- High-performance building envelope.

This is the first of a two-phase expansion project that also will include Learned Hall Engineering Expansion (LEEP2), 135,000 sf of instructional spaces, academic program support and tutoring areas, student fabrication and project spaces, project development, core and research laboratories, and a high bay structure on the KU West Campus. LEEP2 will connect M2SEC and the existing buildings.

| Organization | Project Role |

|---|---|

|

Architect of Record

|

|

|

Laboratory Planning

|

|

|

Interior Design

|

|

|

Construction Administration

|

|

|

MEP Engineer

|

|

|

Professional Engineering Consultants

|

Civil Engineer

|

|

Walter P Moore

|

Structural Engineer

|

|

Confluence

|

Landscape Architect

|

|

JE Dunn

|

Builder

|

|

A&A Sheet Metal Products Inc.

|

Chemical Storage Lockers

|

|

Nor-Lake Inc.

|

Laboratory Environmental Rooms

|

|

Hamilton Scientific

|

Lab Casework

|

|

MOTT Lab

|

Lab Casework

|

|

ETS Lindgren

|

Anechoic Chamber

|

|

Labconco Corporation

|

Fume Hood

|

|

Labconco Corporation

|

Biosafety Cabinets

|

|

Otis Elevator Company

|

Elevator

|

|

Ludy Greenhouse Manufacturing Corporation

|

Greenhouse

|

|

Advanced Glass

|

Glazing

|

|

Advanced Glass

|

Deflagration Panels

|